Automatic storage battery discharging device with optimized heat dissipation channel and use method

An automatic discharge and heat dissipation channel technology, applied in battery circuit devices, different battery charging, circuit devices, etc., can solve the problem that the discharge device cannot realize the automatic charging and discharging function of the battery, the activation function of the battery, cannot automatically monitor the state of the battery, and cannot meet the requirements And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

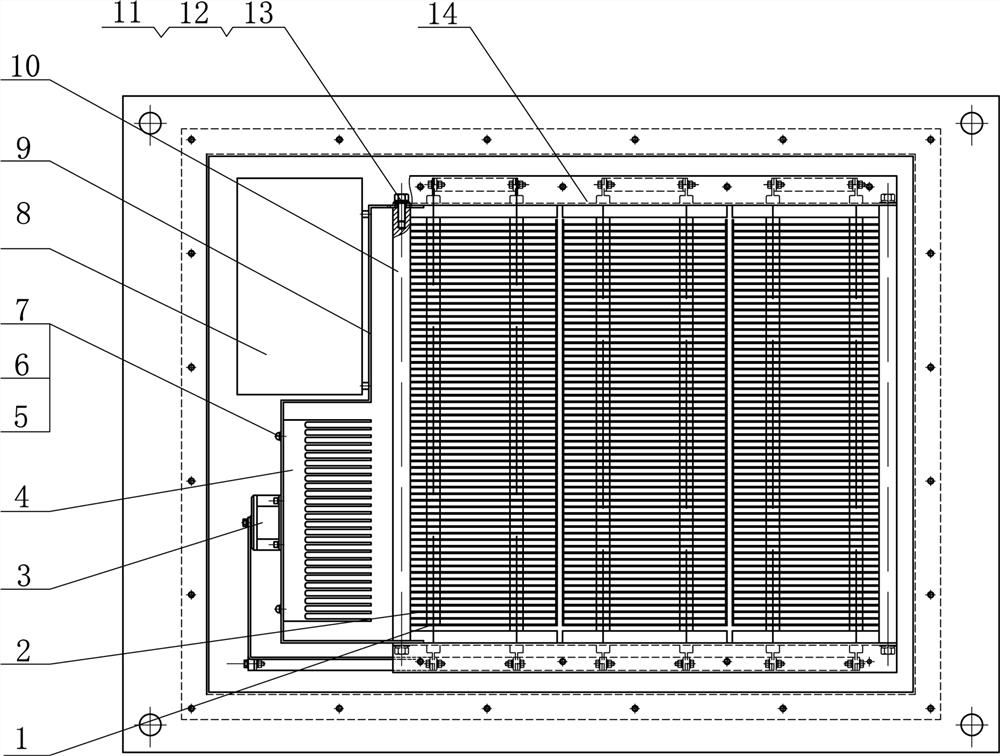

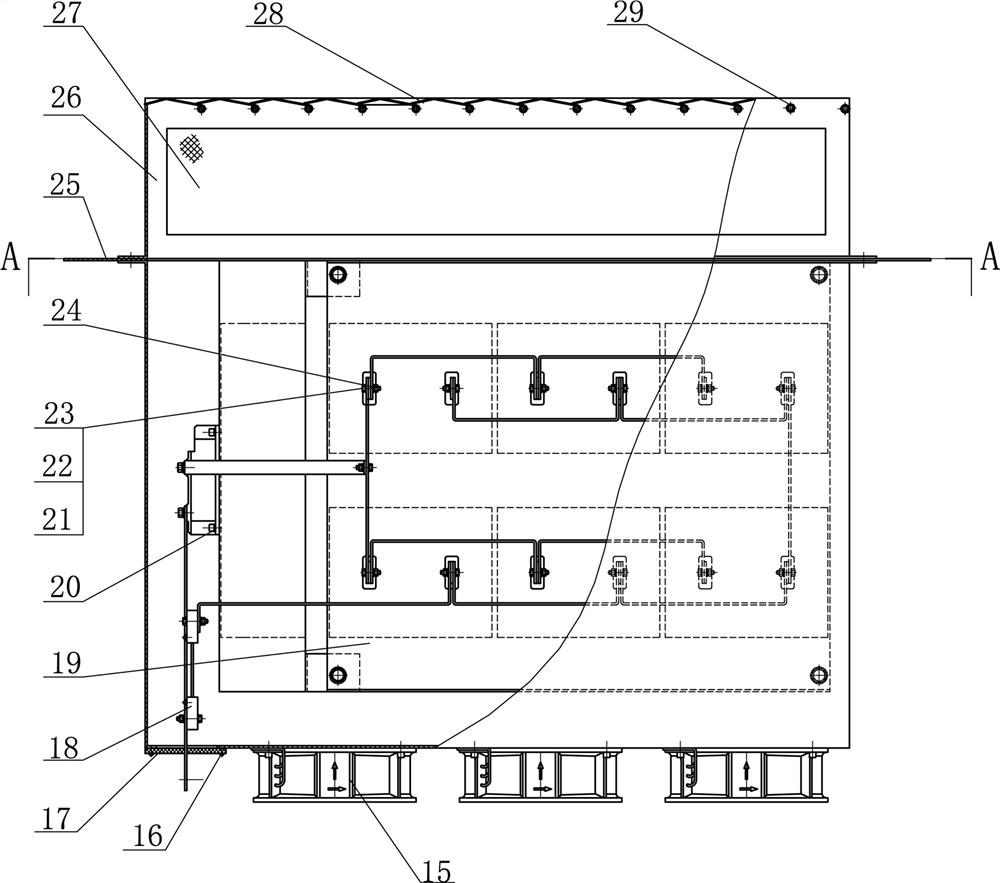

[0039] Such as Figure 1~Figure 7 Among them, an automatic discharge device for storage batteries with optimized heat dissipation channels, including an outer cover 33, a discharge resistor 1 is arranged inside the outer cover 33, and both ends of the discharge resistor 1 are connected to the left side plate 14 and the right side plate 19 of the outer cover 33; the surface of the discharge resistor 1 The heat dissipation fins 2 are inlaid; the heat insulation plate 9 is connected between the left side plate 14 and the right side plate 19 to form a rectangular heat dissipation air duct; the top of the left side plate 14 and the right side plate 19 is connected with an annular top plate 25, and the surface of the top plate 25 is A fixing hole is provided to connect with the DC cabinet.

[0040] Preferably, a top cover 26 is connected above the top plate 25, and the side surface of the top cover 26 is provided with cooling holes, and the surface of the cooling holes is connected ...

Embodiment 2

[0048] Preferably, the above-mentioned method for using an automatic battery discharge device with optimized heat dissipation channels includes the following steps:

[0049] S1, remove the top cover plate of the original DC panel, install the discharge device on the top of the DC panel as a whole, the outer cover 33 is located in the DC panel, and the top plate 25 is connected and fixed to the top edge of the DC panel;

[0050] S2, connect the positive terminal 34 and negative terminal 35 with the discharge switch of the battery pack with cables that meet the requirements; install the operation panel on the front door panel of the cabinet, and use the communication cable to connect the RS485 communication port of the automatic discharge module to the DC system The centralized monitor is connected to the RS485 communication port of the battery inspection instrument, and the parameters are adjusted and then put into operation;

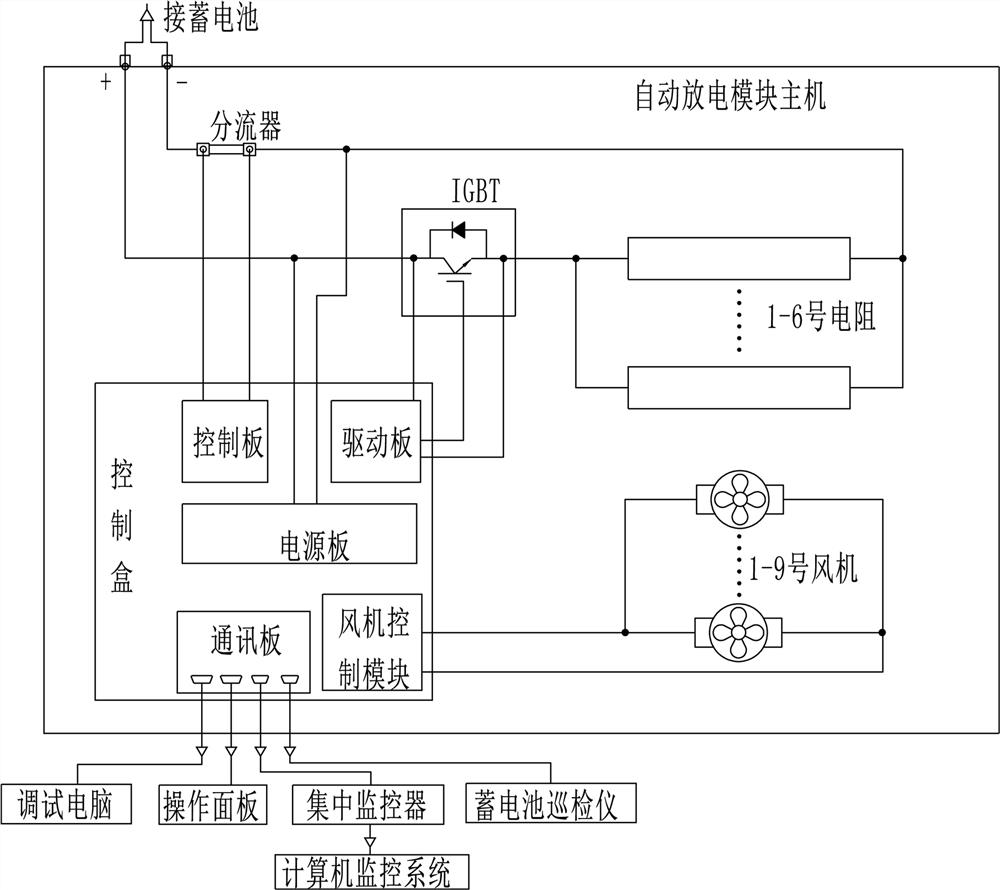

[0051] S3, such as Figure 8 As shown in the figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com