Patents

Literature

44results about How to "Control duty cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rotating speed control method and device of brushless DC fan, fan and refrigerator

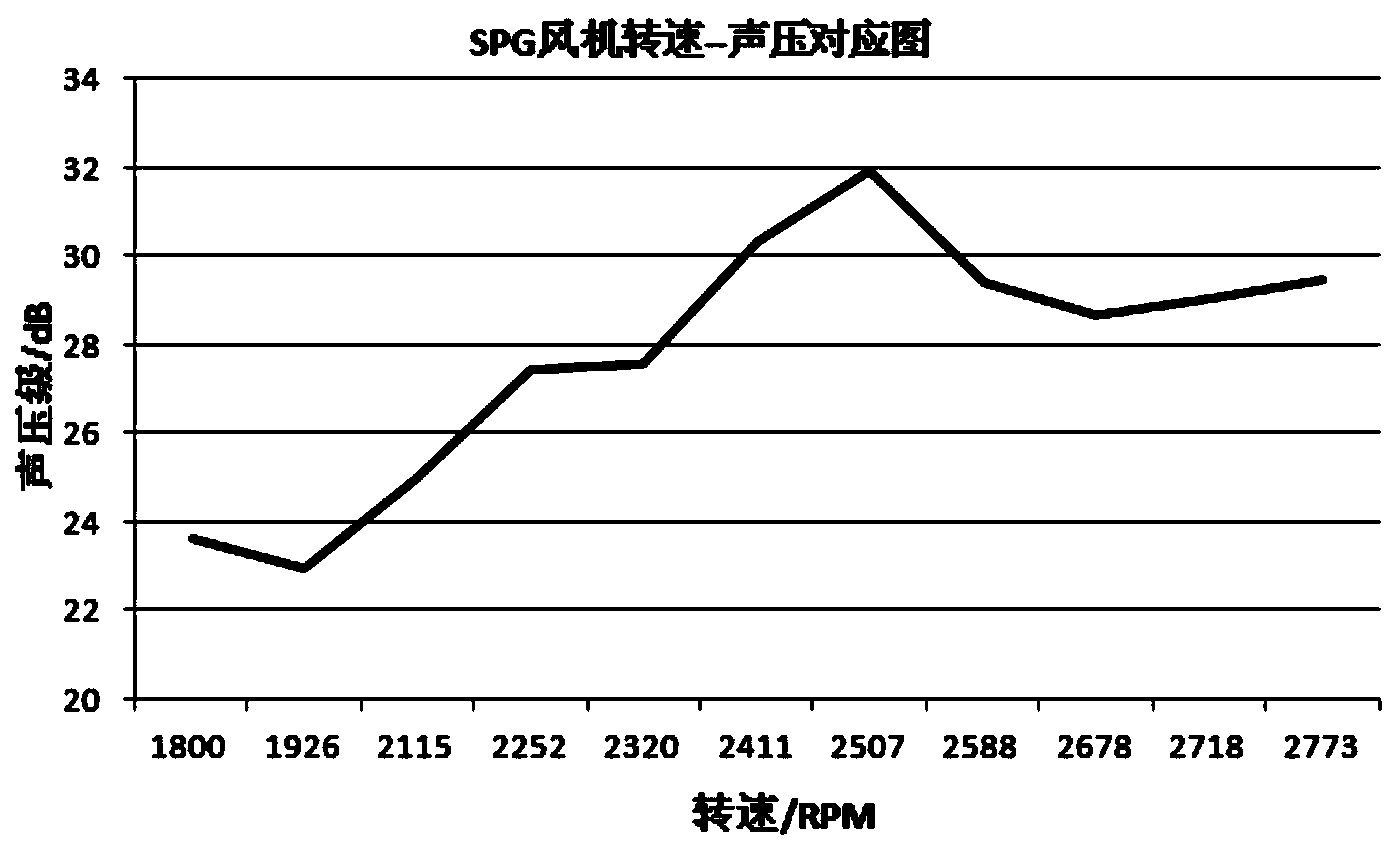

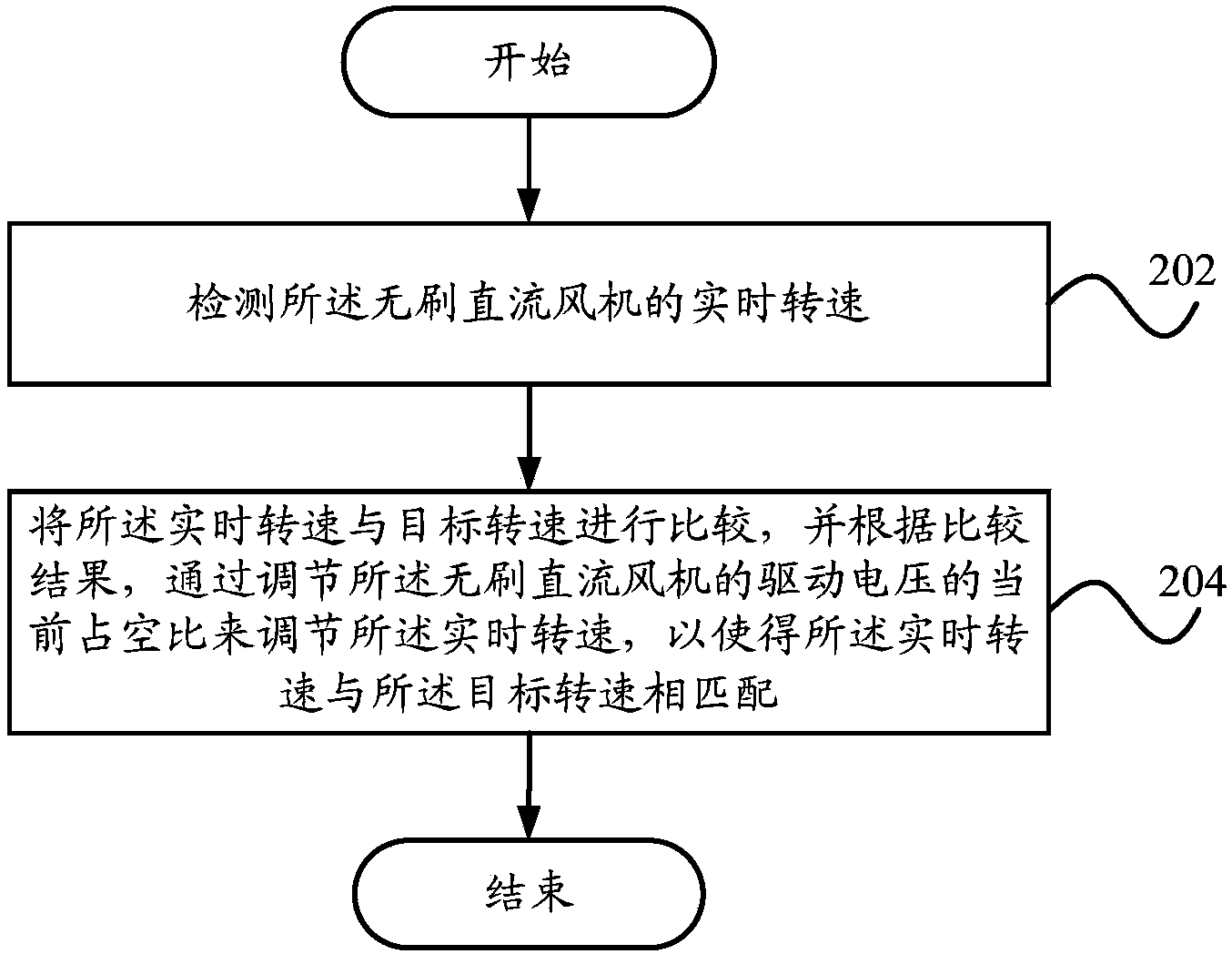

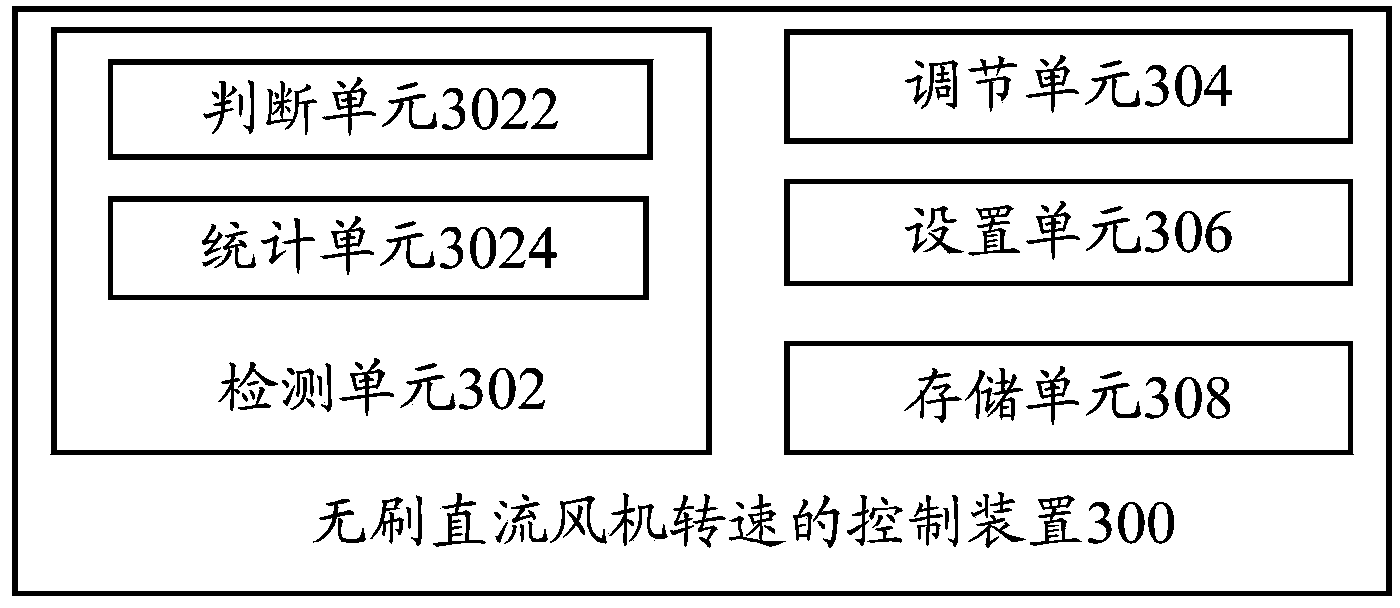

InactiveCN104265669AReduce noiseHigh control precisionPump controlNon-positive displacement fluid enginesRefrigerated temperatureDuty cycle

The invention provides a rotating speed control method and device of a brushless DC fan, the brushless DC fan and a refrigerator. The rotating speed control method of the brushless DC fan comprises the following steps: detecting the real-time rotating speed of the brushless DC fan; comparing the real-time rotating speed with a target rotating speed; adjusting the current duty ratio of the driving voltage of the brushless DC fan according to the comparison result, so as to adjust the real-time rotating speed to be matched with the target rotating speed. According to the technical scheme, the rotating speed control method of the brushless DC fan has the advantages that the duty ratio of the driving voltage of the fan can be accurately controlled, thus the output voltage of the fan can be accurately controlled, and as a result, the accurate control of the rotating sped of the fan is realized, and the noise of the refrigerator is minimized.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

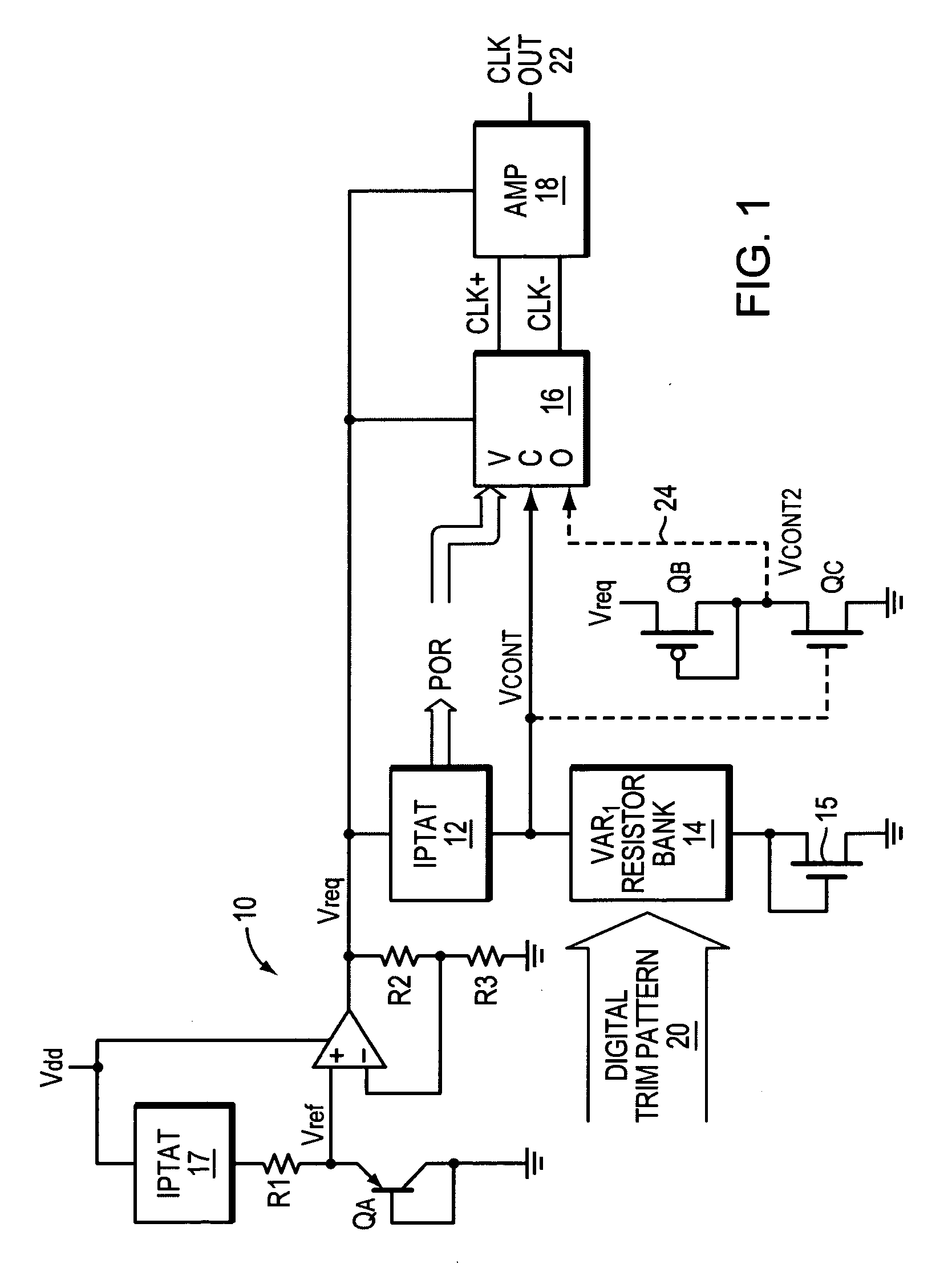

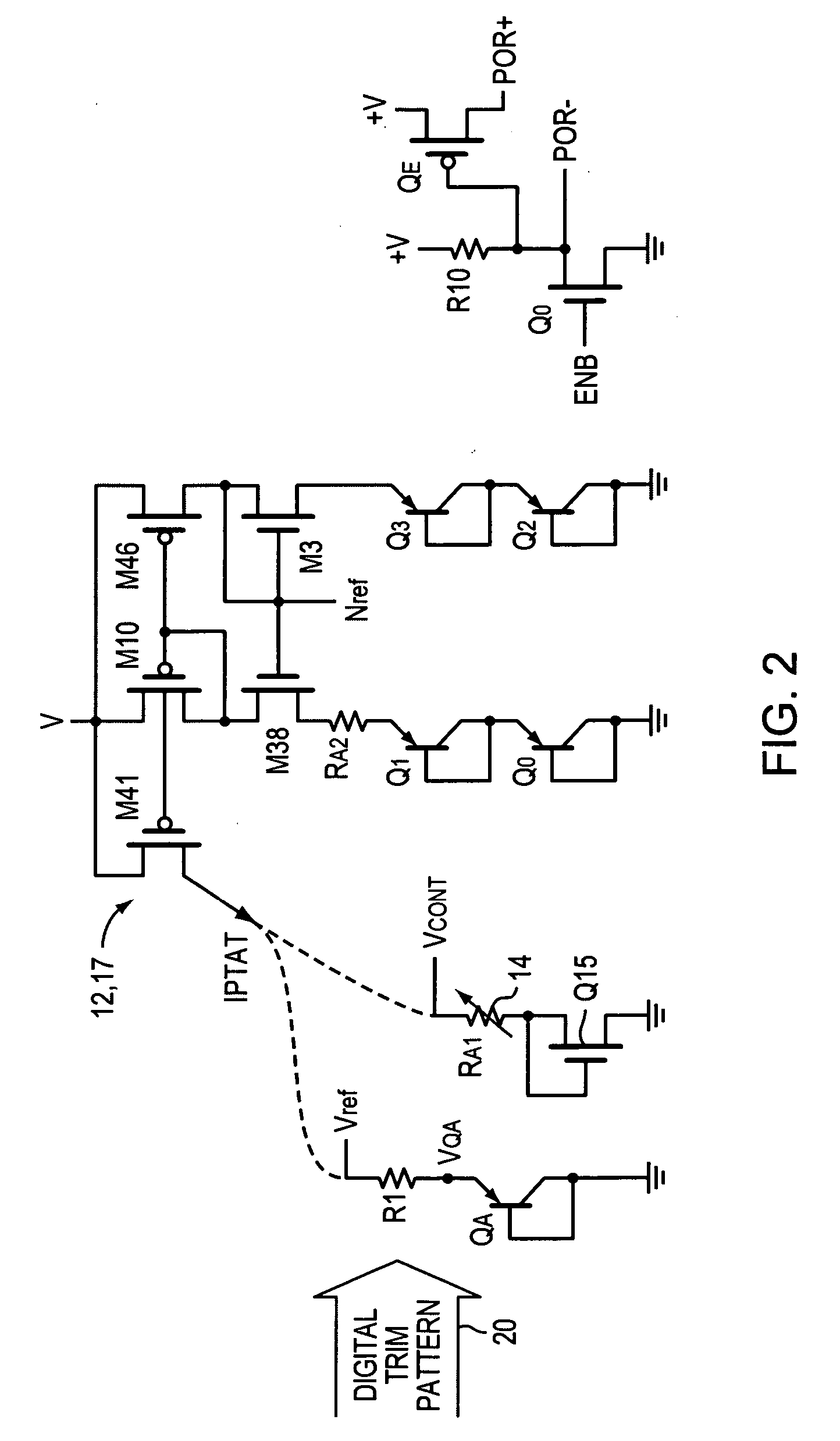

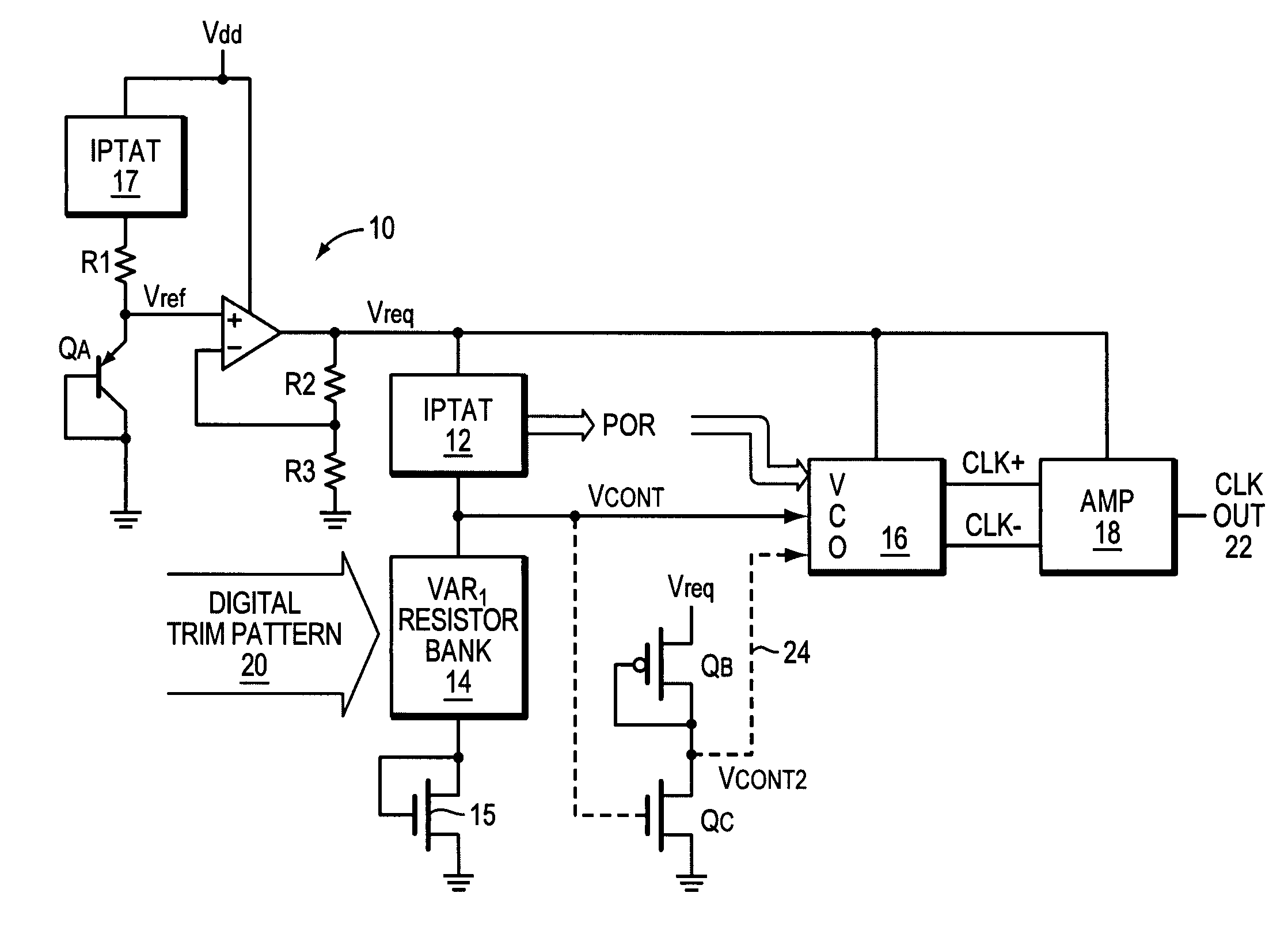

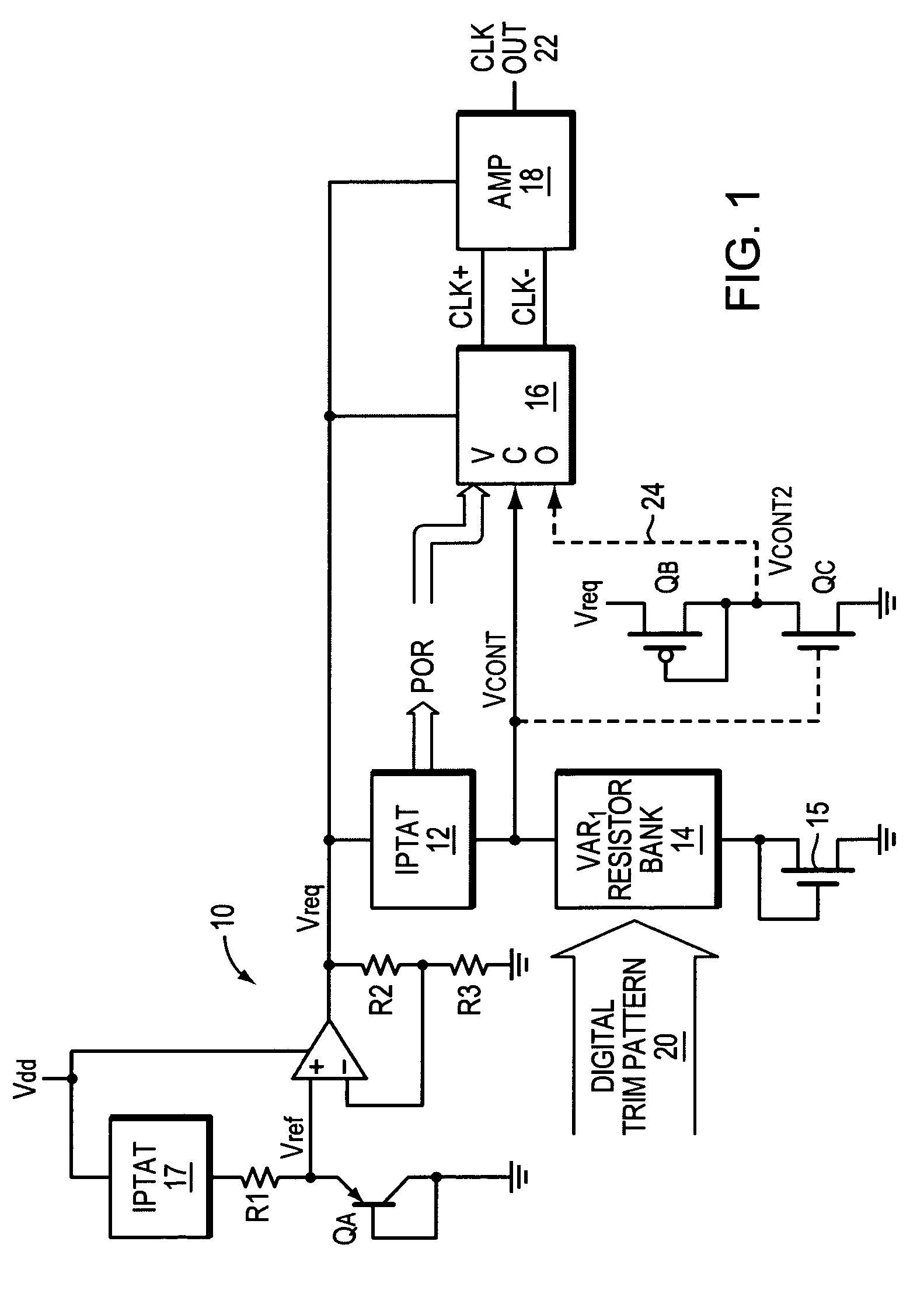

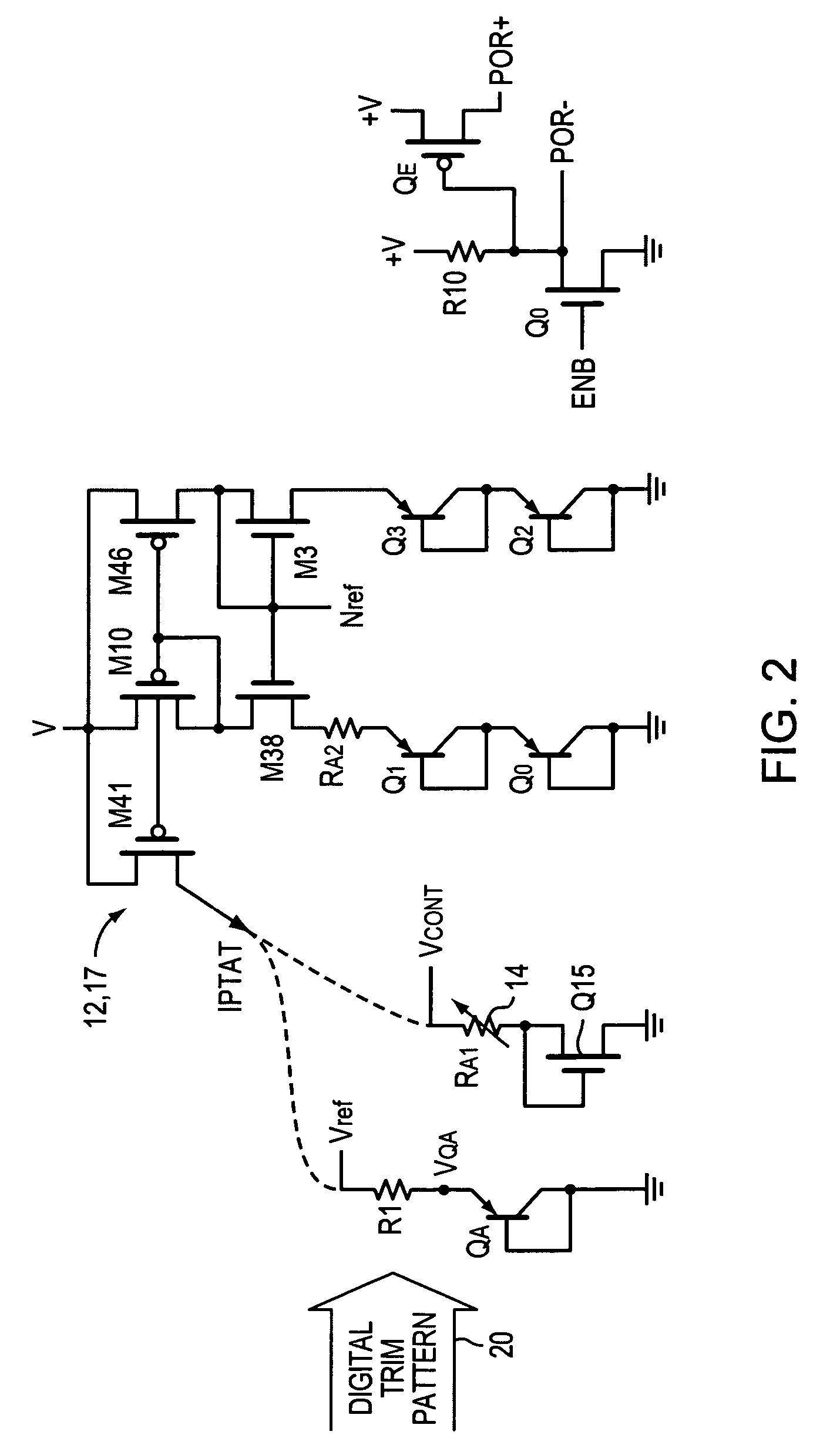

Low power, temperature and frequency, tunable, on-chip clock generator

ActiveUS20070273453A1Offset effectControl duty cyclePulse automatic controlGenerator stabilizationElectrical resistance and conductanceManufacturing technology

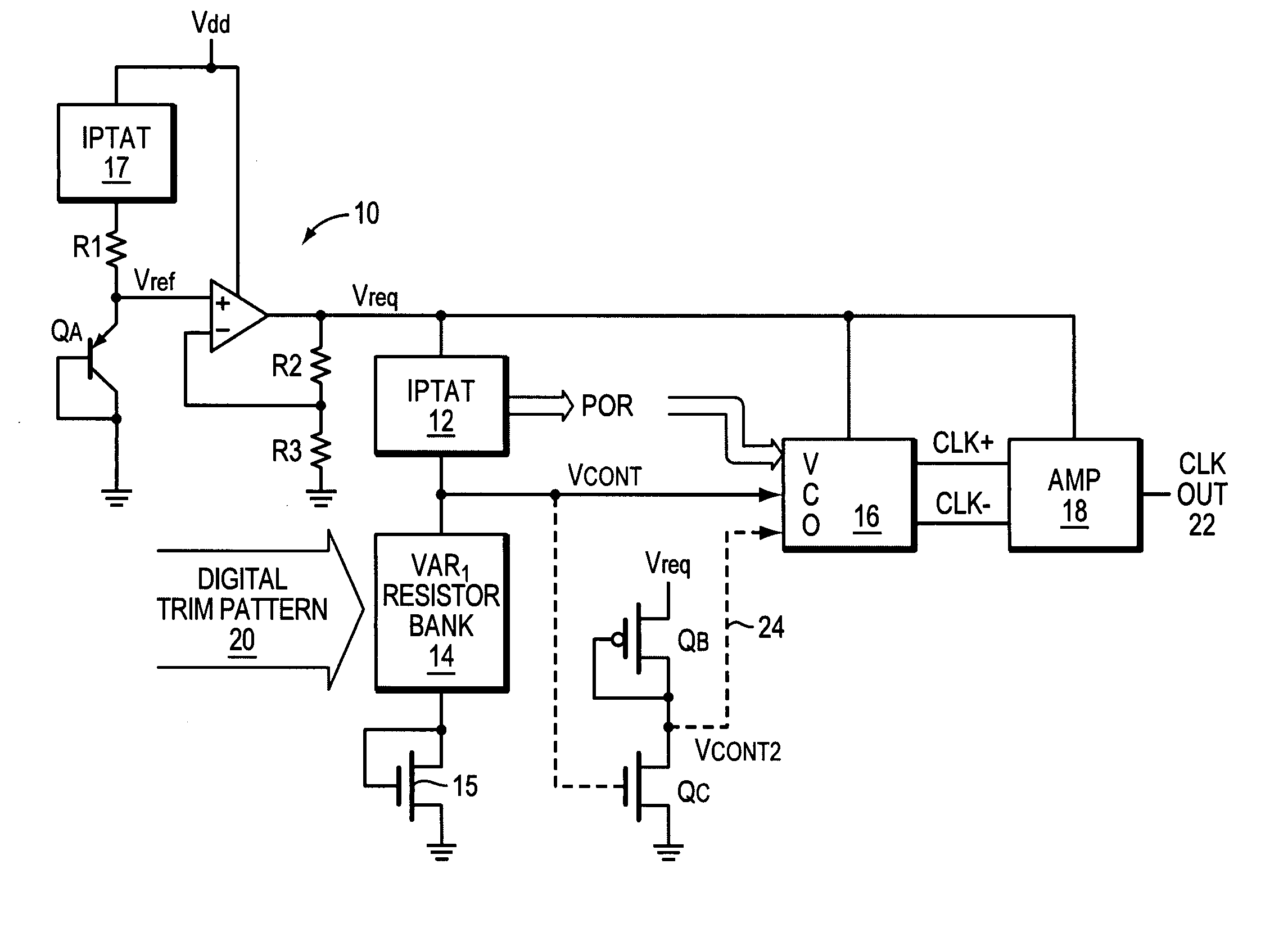

A tunable, low power clock generator employs a voltage regulator, one or current generators and a variable resistor bank that, together, produce a control voltage for trimming a VCO. The control voltage is arranged to also compensate, at least, for the variables of temperature, supply voltage and fabrication processes as they affect the VCO output frequency. The current generator is well characterized over the variables discussed and the resistor bank is a flexible series / parallel array of resistors made from differing materials exhibiting different temperature coefficients. The resistor bank provides for various overlapping resistance values simultaneously with various overlapping temperature coefficients wherein the temperature coefficient profile of the clock generator over frequency and temperature is controlled.

Owner:SEMICON COMPONENTS IND LLC

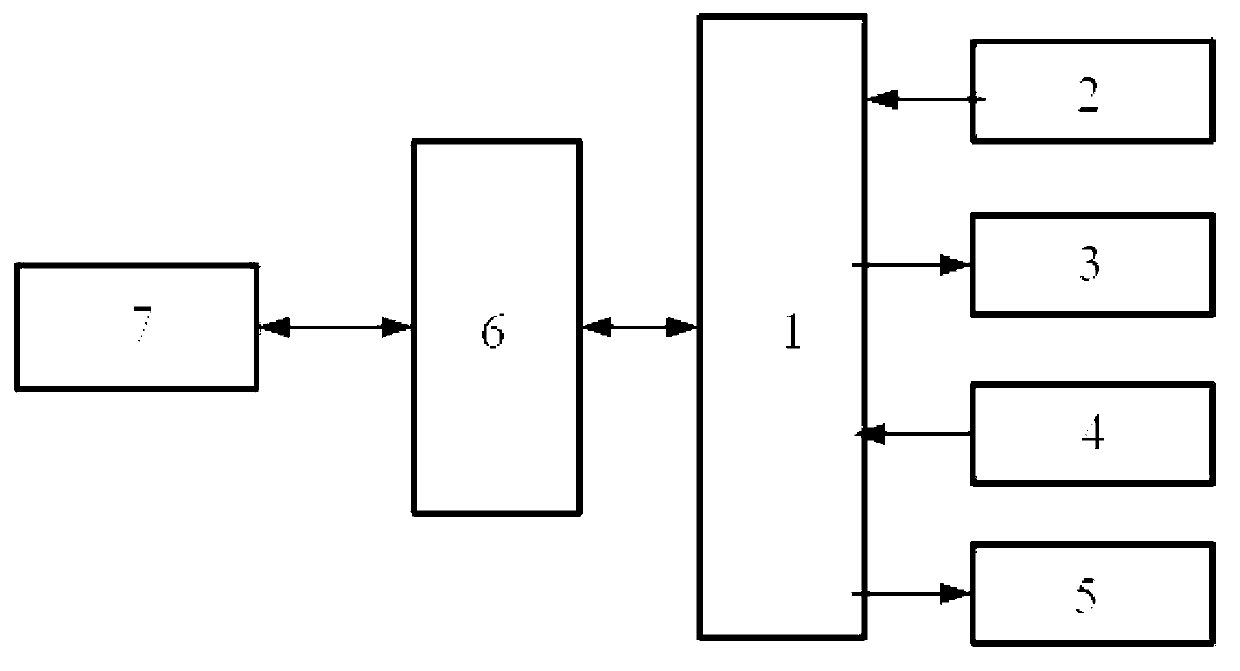

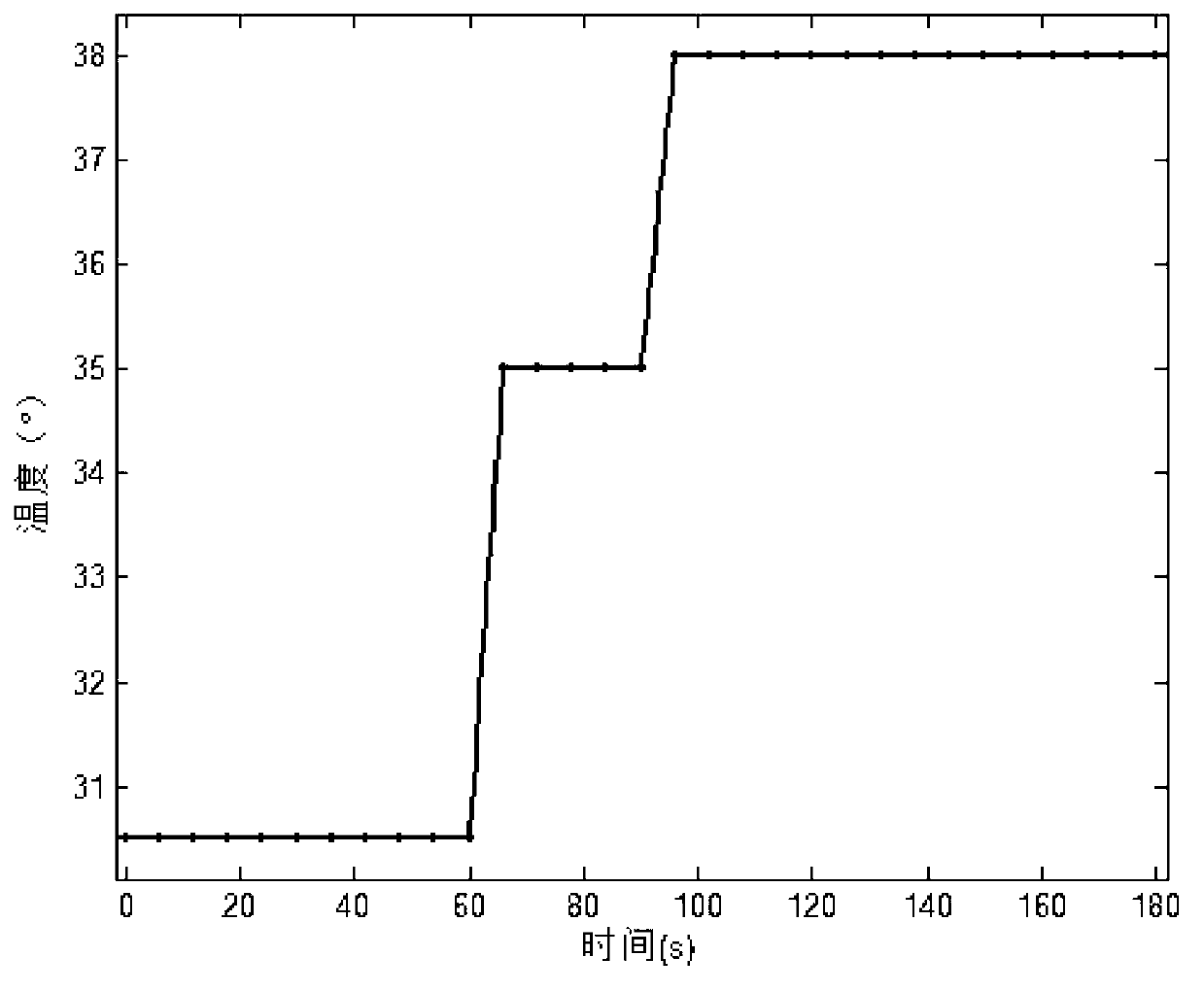

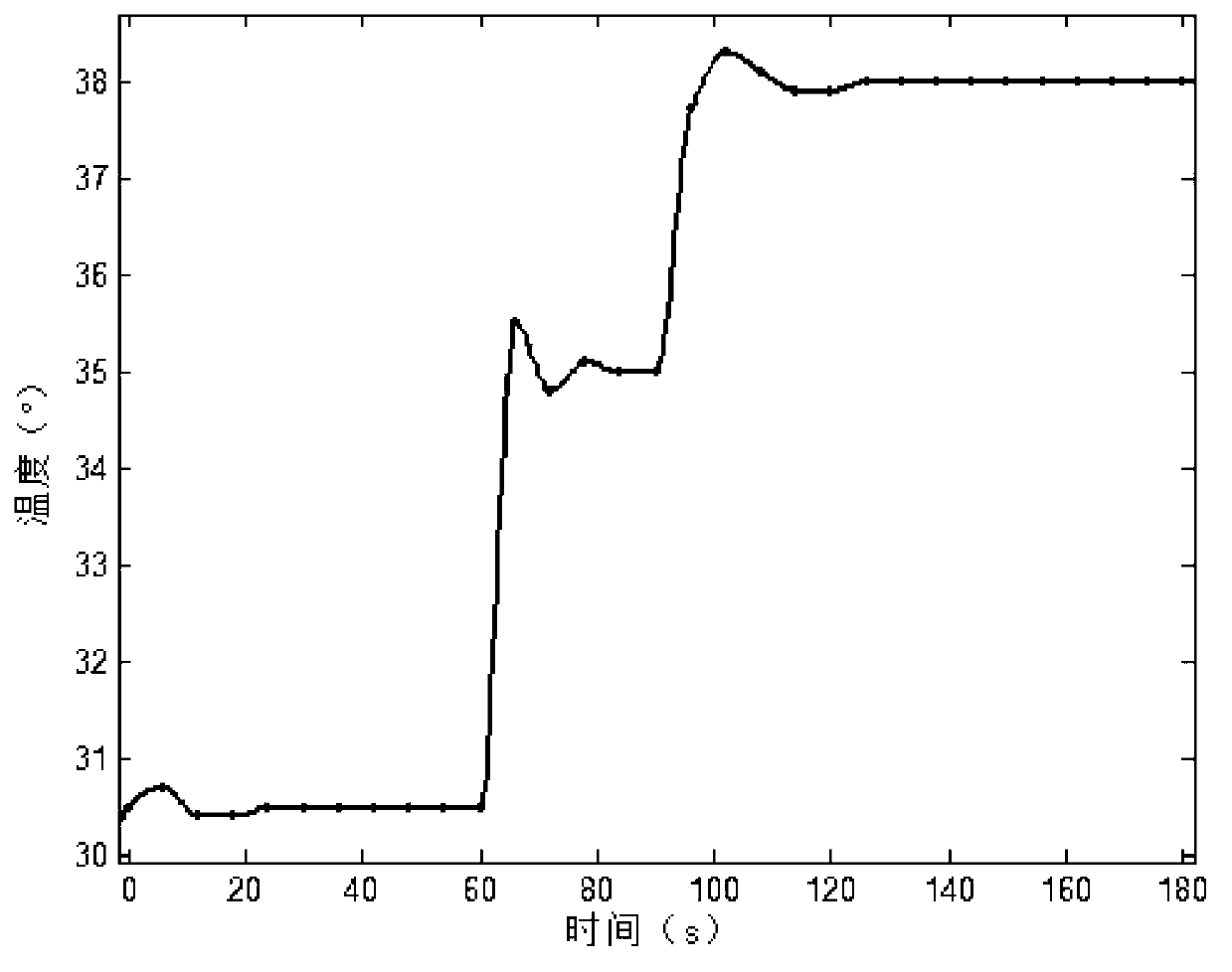

Temperature control system

InactiveCN103279155AIncrease the level of automationRealize temperature gradient change controlAuxillary controllers with auxillary heating devicesInteractive softwareDisplay device

The invention discloses a temperature control system, which comprises a lower computer and an upper computer, wherein the lower computer consists of an automatic voltage regulation (AVR) single chip microcomputer, a temperature sensor, a light-emitting diode (LED) display, a temperature setting circuit and a temperature heating circuit; and the upper computer consists of a personal computer (PC) and interactive software. According to the system, temperature and time for keeping the temperature can be input to the upper computer according to a temperature curve required by a user, the lower computer controls the gradience of the temperature and the system can meet requirements of users on different temperatures at different moments, responds sensitively and has higher accuracy.

Owner:CHANGAN UNIV

Low power, temperature and frequency, tunable, on-chip clock generator

ActiveUS7535309B2Control duty cyclePulse automatic controlGenerator stabilizationElectrical resistance and conductanceVoltage regulation

A tunable, low power clock generator employs a voltage regulator, one or current generators and a variable resistor bank that, together, produce a control voltage for trimming a VCO. The control voltage is arranged to also compensate, at least, for the variables of temperature, supply voltage and fabrication processes as they affect the VCO output frequency. The current generator is well characterized over the variables discussed and the resistor bank is a flexible series / parallel array of resistors made from differing materials exhibiting different temperature coefficients. The resistor bank provides for various overlapping resistance values simultaneously with various overlapping temperature coefficients wherein the temperature coefficient profile of the clock generator over frequency and temperature is controlled.

Owner:SEMICON COMPONENTS IND LLC

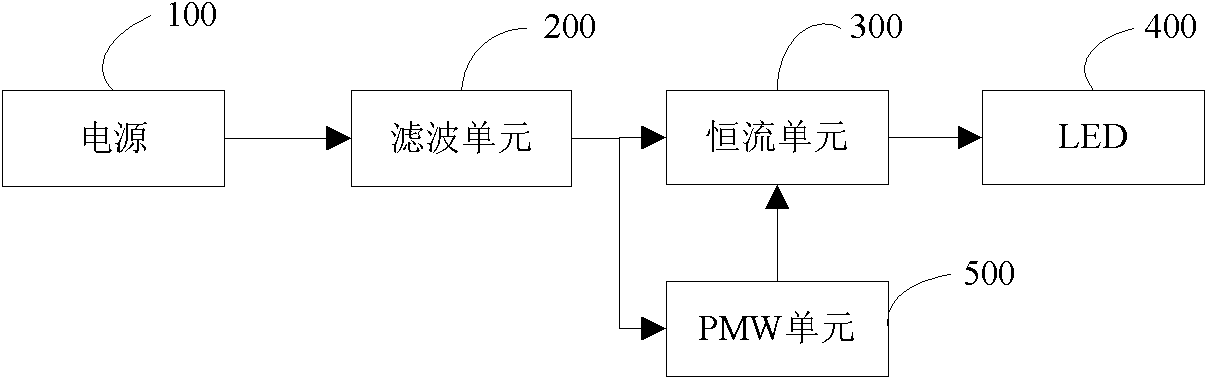

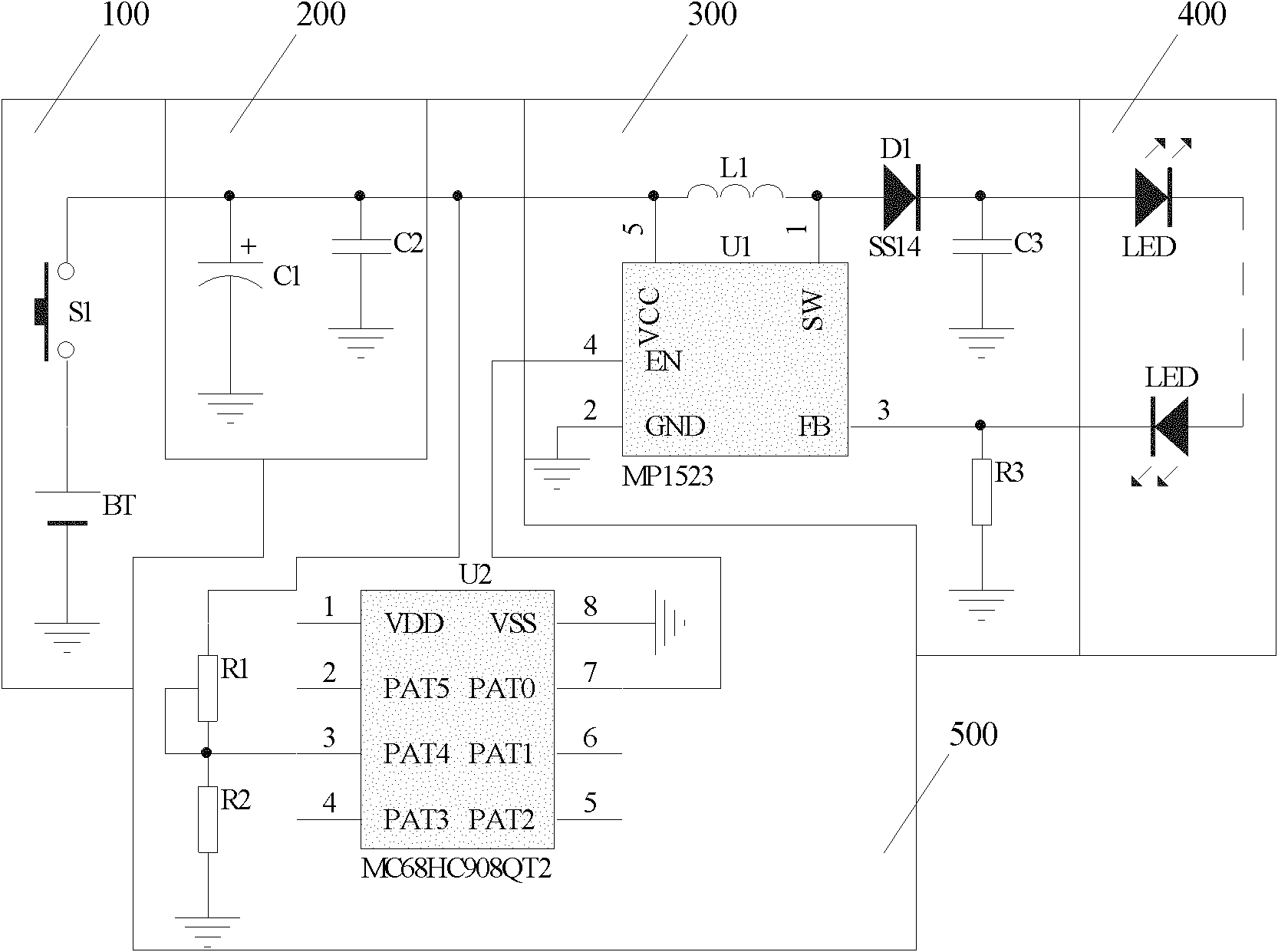

LED (Light Emitting Diode) constant-current drive circuit and LED lamp using same

InactiveCN102612196AMeet the needs of dimmingRealize stepless dimmingPoint-like light sourceElectric lightingElectricityEngineering

The invention belongs to the field of LED (Light Emitting Diode) drive circuits and discloses an LED constant-current drive circuit and an LED lamp using the same. The LED constant-current drive circuit comprises a power supply, a filtering unit, a constant-current unit and a PWM (Pulse Width Modulation) unit, wherein the filtering unit is electrically connected between the power supply and the constant-current unit, the constant-current unit supplies a constant current to an LED, the PWM unit is electrically connected with the constant-current unit, and the PWM unit controls the constant-current unit through outputting a variable PWM pulse duty factor. The design of the circuit is simple and reliable, and the stepless dimming of the LED can be realized through only changing the variable PWM pulse duty factor output by the PWM unit, so that the circuit has the advantages of simplicity, convenience, stability and reliability.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

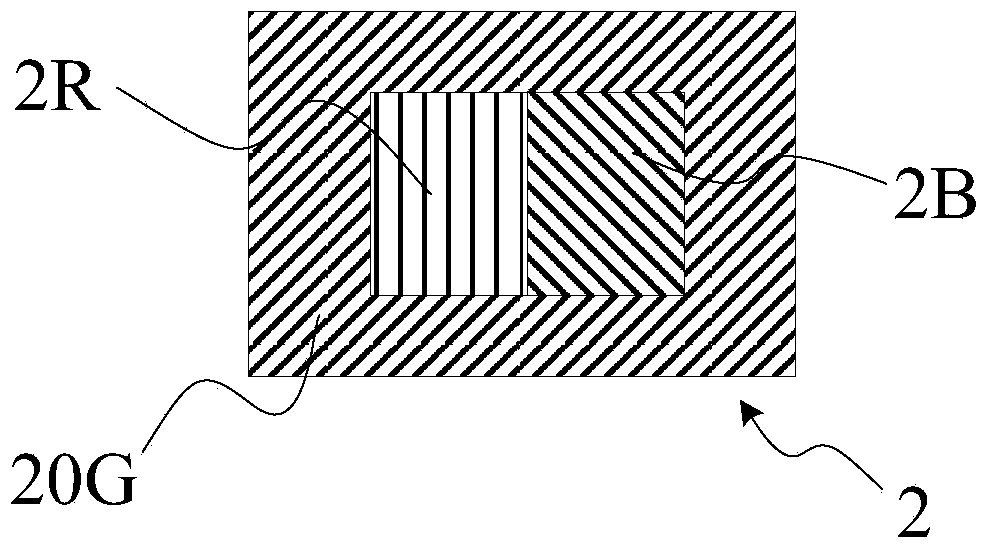

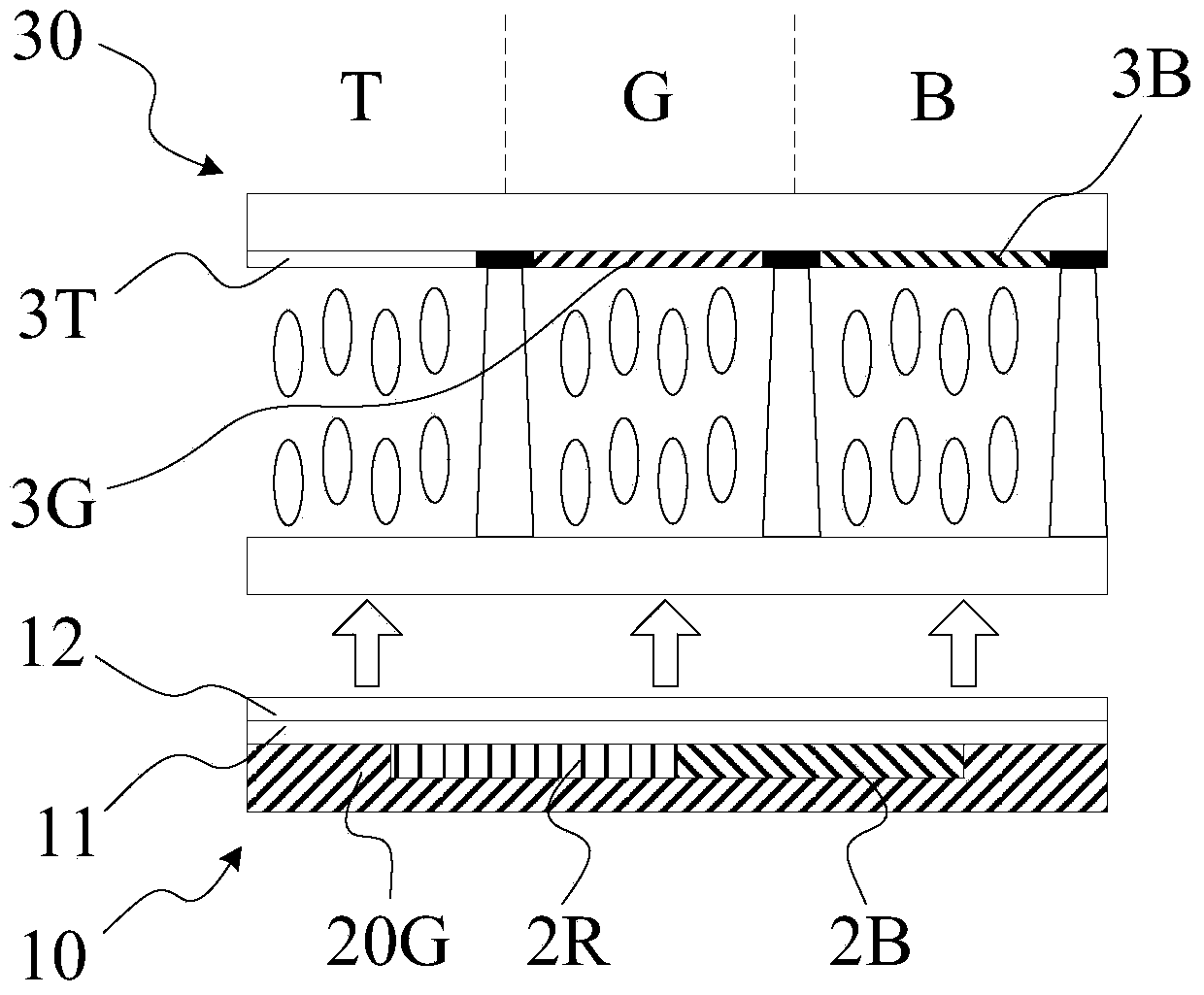

Backlight module, display device and drive method of display device

InactiveCN104019404AReduce power consumptionIncrease profitStatic indicating devicesSpectral modifiersDisplay devicePersonal computer

The invention discloses a backlight module, a display device and a drive method of the display device, and belongs to the technical field of displaying. The technical problem that the color crack phenomenon exists in an existing FSC liquid crystal displayer is solved. The backlight module comprises a controller and a plurality of partition backlights. Each partition backlight comprises at least two light sources with different colors, wherein the two light sources are independently driven. The controller controls the turning-on time of the light sources with different colors in all partition backlights. The backlight module can be used for liquid crystal display televisions, liquid crystal displays, mobile phones, tablet personal computers and other display devices.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

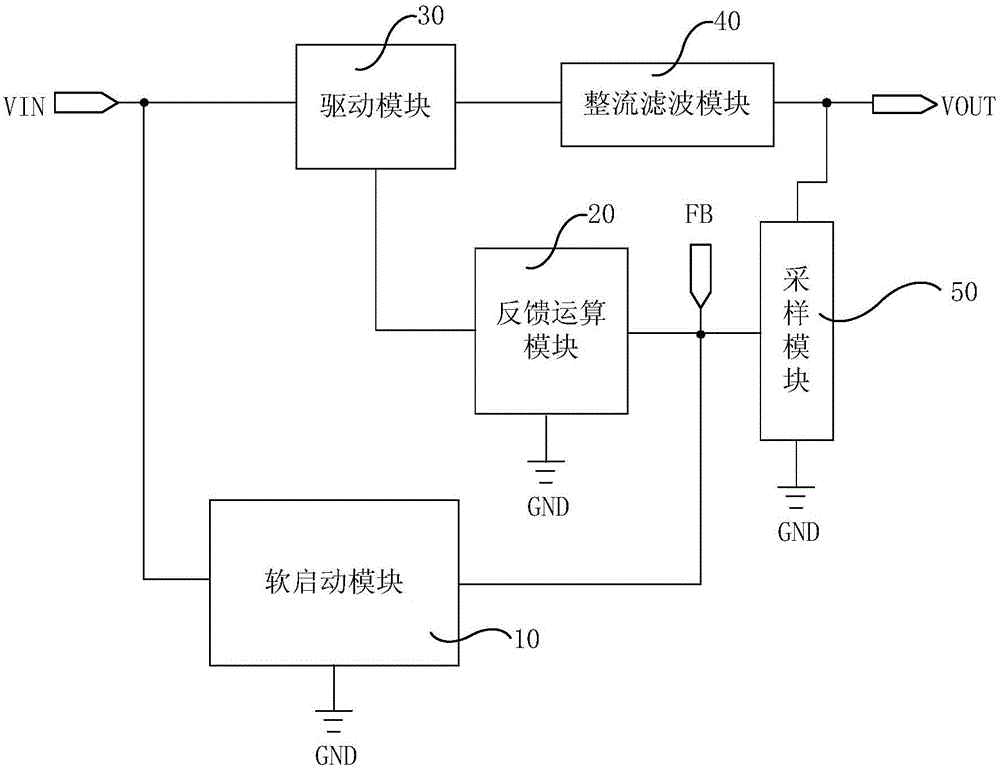

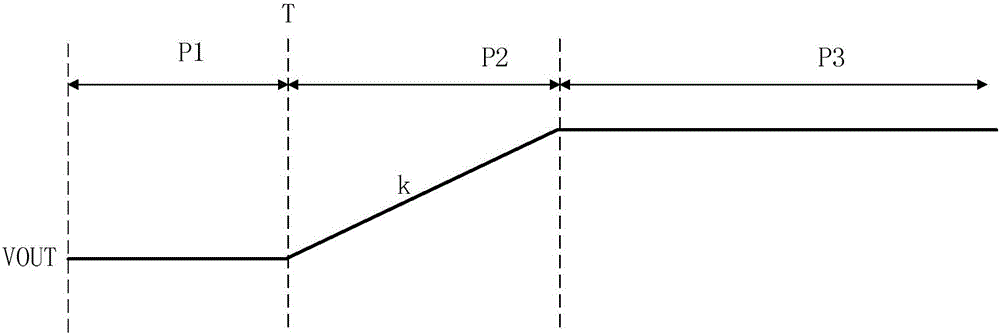

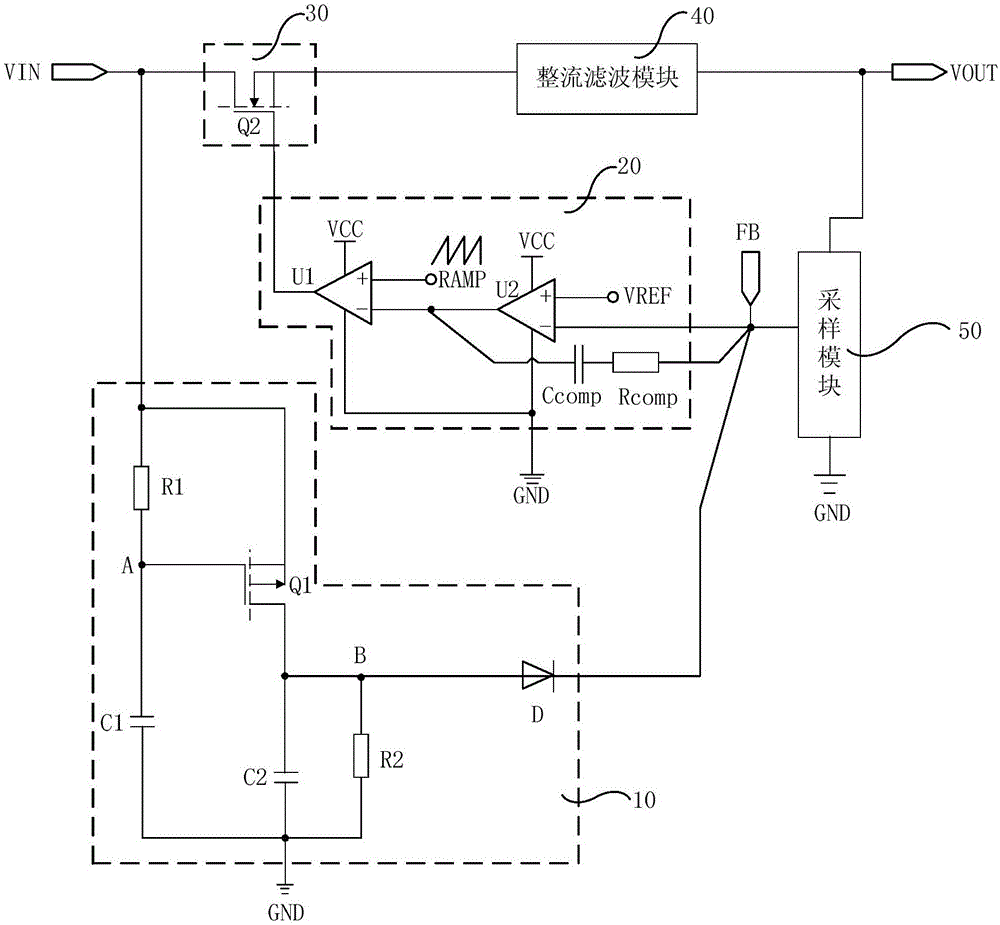

Soft start power supply circuit and control method thereof, as well as display device

ActiveCN106357104APrevent overshootControl duty cycleElectroluminescent light sourcesAc-dc conversionFiltrationComputer module

The embodiment of the invention provides a soft start power supply circuit and a control method thereof, as well as a display device, relates to the technical field of display drivers, and aims to solve the problem of overshooting of power supply voltage output at the moment of starting. The soft start power supply circuit comprises a soft start module for pulling up the potential at a feedback voltage end to a potential at an input voltage end, or pulling down the potential at the feedback voltage end to a potential at a grounding end, a feedback operation module for controlling on and off of the driving module according to the voltage of the feedback voltage end, a driving module for outputting a signal of the input voltage end to a rectification and filtration module in a start state, the rectification and filtration module for rectifying and filtering the signal output by the rectification and filtration module and outputting the signal to an output voltage end, and a sampling module for sampling the signal of the output voltage end and outputting the signal to the feedback voltage end. The soft start power supply circuit is used for realizing soft start in a power supply voltage outputting process.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

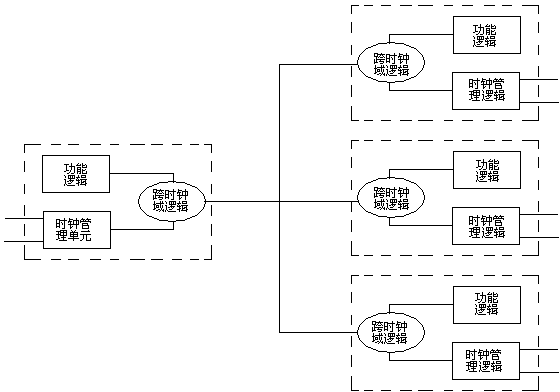

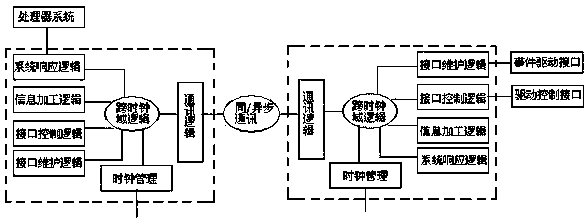

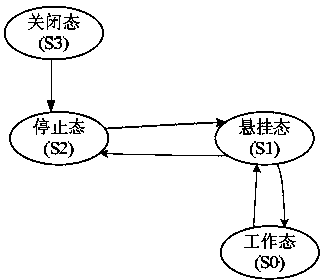

FPGA zero-dynamic power consumption design method

ActiveCN103926996AReduce power consumptionControl duty cyclePower supply for data processingEmbedded systemDesign methods

The invention discloses an FPGA zero-dynamic power consumption design method. A system clock tree and local clock trees are established. Clock management logic is established according to a state machine method and is established through the steps that functional logic or clock signal work of a clock drive source is identified as a work state, the function logic or the stagnation of the clock drive source is identified as a stop state, a hanging state used for judging the control method of a clock is established, and information interaction used for switching working modes and multiple systems or multiple clock domains is established. By setting the clock management logic based on state detection and clock drive control, the clock drive source for the corresponding functional logic is powered off, and the power consumption lowering design method for the 0Hz clock is achieved. Thus, the duty ratio of reactive power in the device is controlled, and the maximum efficiency for use of dynamic power consumption resources is achieved.

Owner:SHANGHAI SPACEFLIGHT ELECTRONICS & COMM EQUIP RES INST

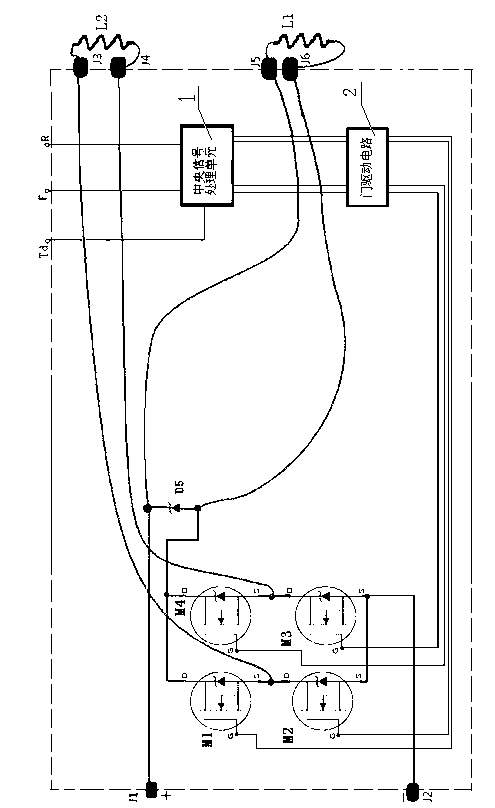

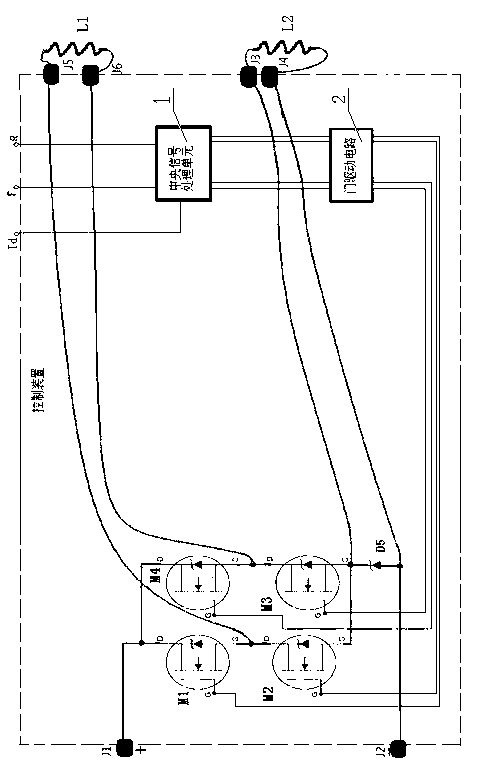

Series direct-current motor four-switch topological device and control method thereof

InactiveCN103312239AControl duty cycleRealize commutationStopping arrangementsGenerator control by field variationDriver circuitCurrent meter

The invention discloses a series direct-current motor four-switch topological device and a control method thereof, and relates to the technical field of brushed direct-current motors. The series direct-current motor four-switch topological device comprises a full-bridge circuit, a center signal processing unit, a gate drive circuit and a flyback diode, wherein the full-bridge circuit comprises semiconductor switch elements. The full-bridge circuit which is composed of the semiconductor switch elements is utilized to control one of windings of the series direct-current motor, then the other winding is in series connection between the full-bridge circuit and bus directly, and the flyback diode is in parallel connection with the winding reversely. Since one of two power supply switches of the full-bridge circuit can be selected to control current direction of the windings connected to the full-bridge circuit, reversing of electromagnetic torque of the motor is realized.

Owner:YANGZHOU DADE JIDIAN TECH

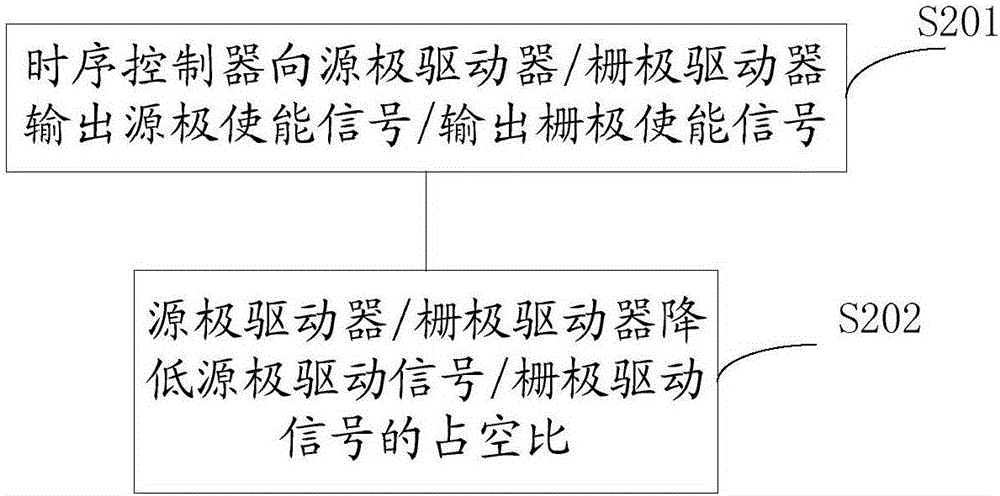

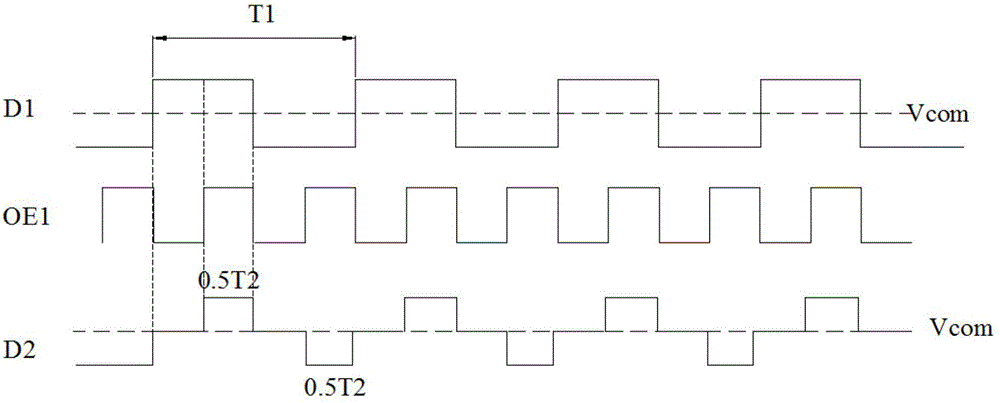

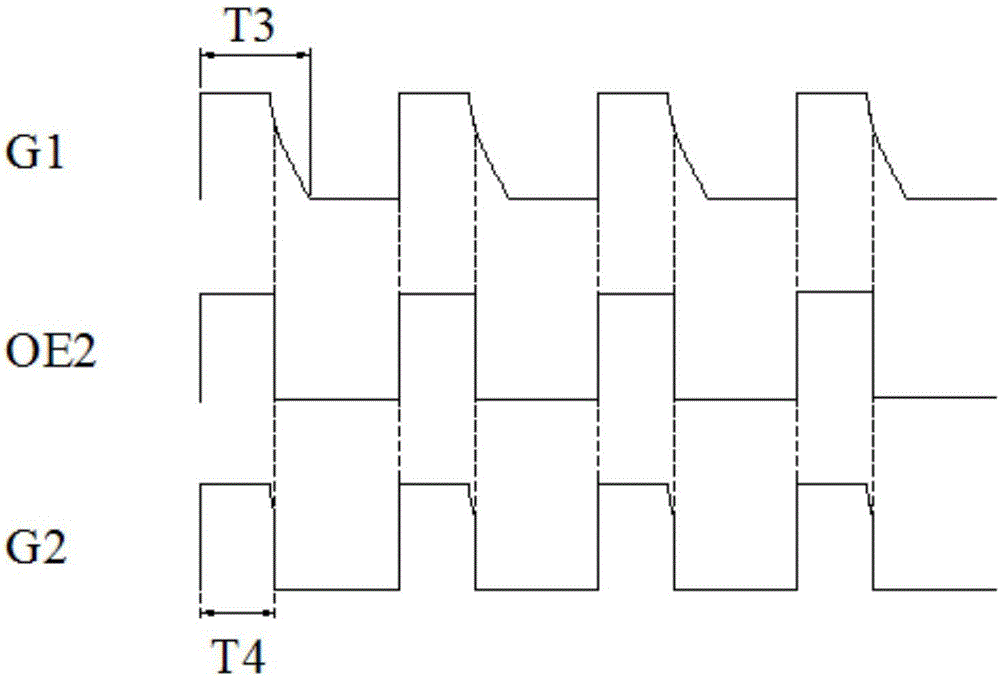

Liquid crystal display, driving method thereof, and electronic device

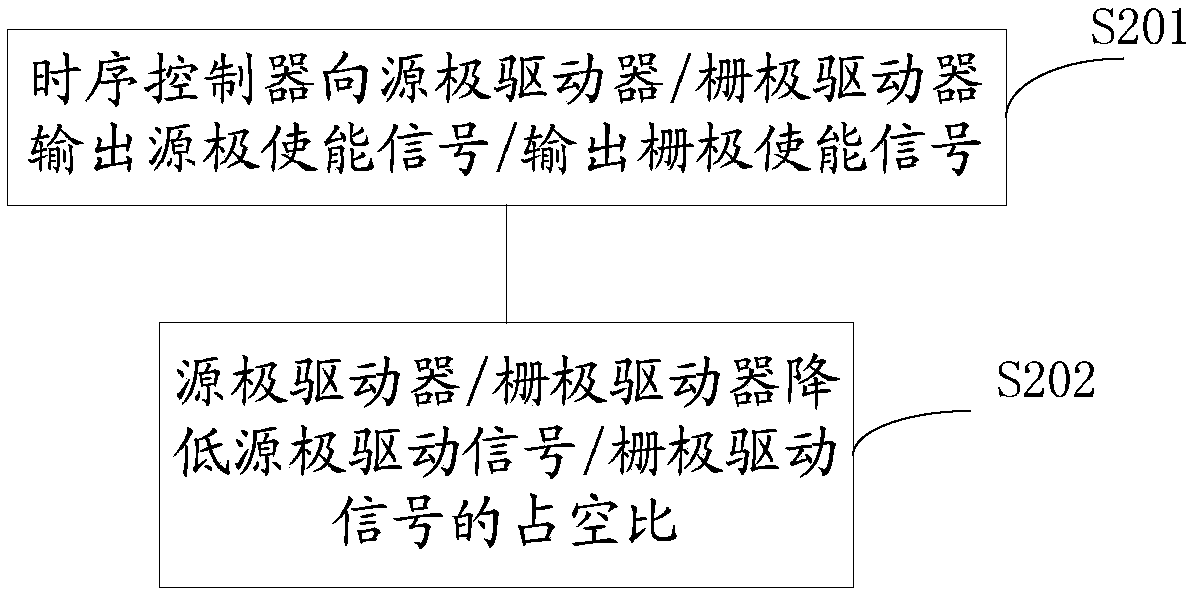

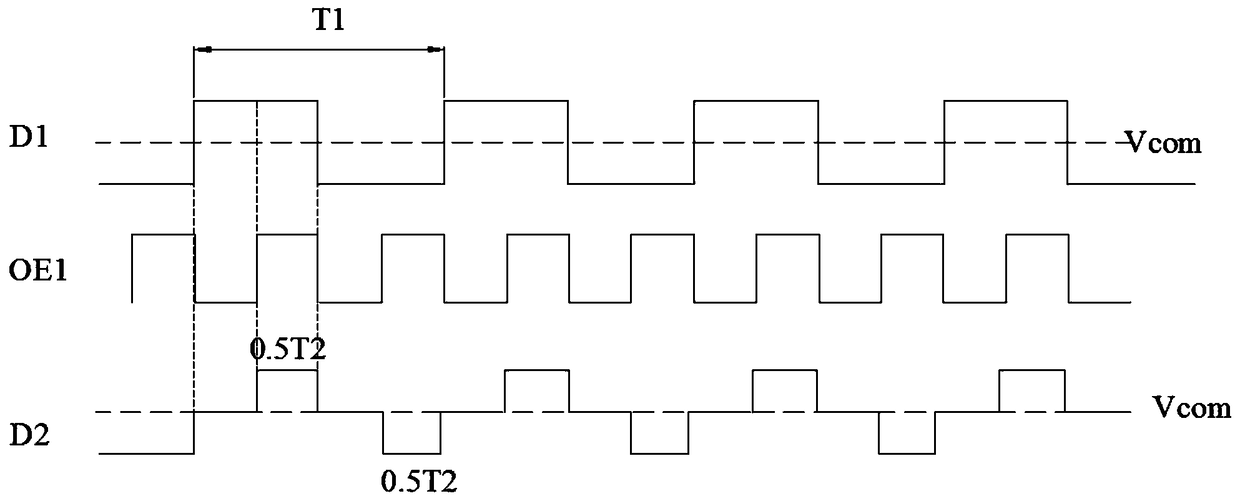

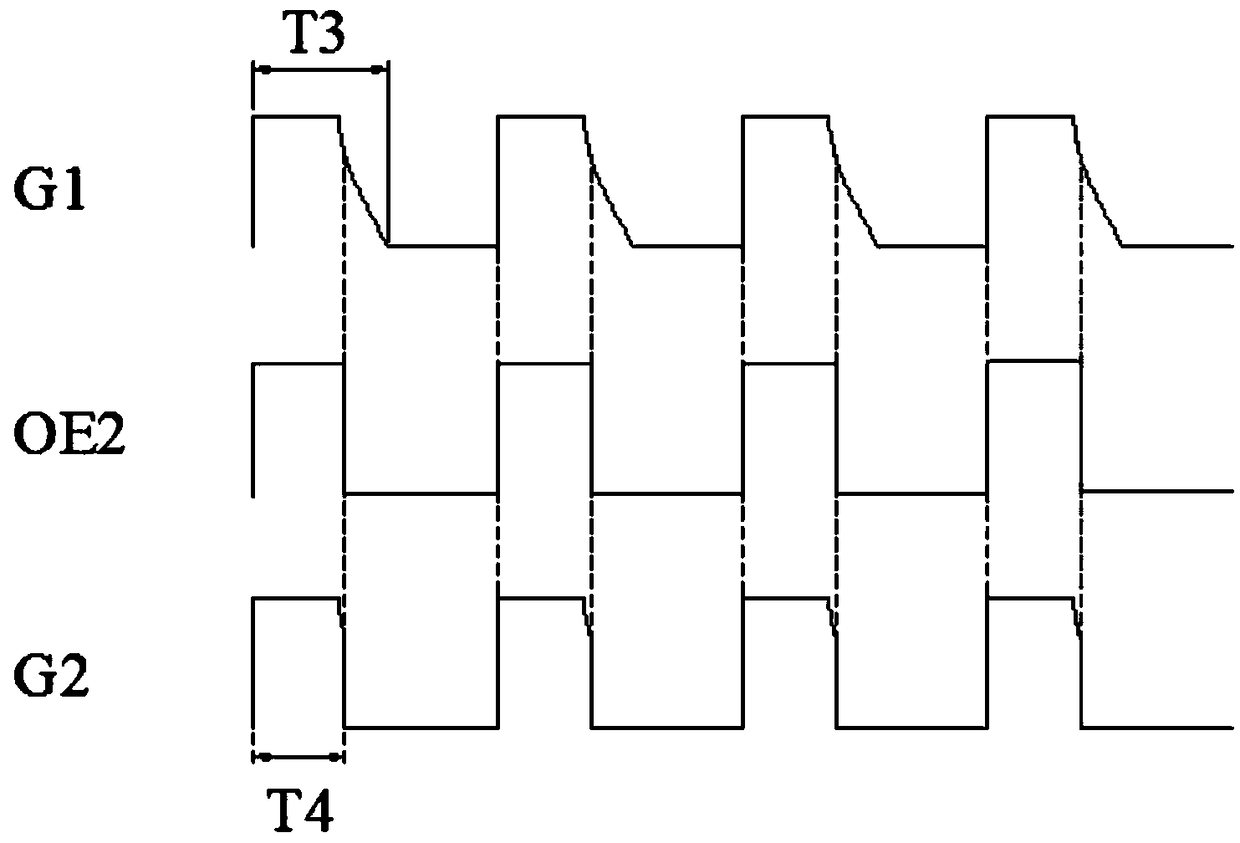

ActiveCN106098012AIncrease opening ratioAchieve color cast compensationStatic indicating devicesTime scheduleLiquid-crystal display

The invention provides a driving method of a liquid crystal display. The driving method of the liquid crystal display comprises steps that a time schedule controller is used to output a source electrode enabling signal to a source electrode driver, and is used to output grid electrode enabling signal to a grid electrode driver; the source electrode driver is used to receive the source electrode enabling signal, and a duty ratio of a source electrode driving signal output to a source electrode line is reduced based on the source electrode enabling signal; the grid electrode driver is used to receive the grid electrode enabling signal, and a duty ratio of a grid electrode driving signal output to a grid electrode line is reduced based on the grid electrode enabling signal. The invention also provides the liquid crystal display and an electronic device. The liquid crystal display can be provided with a four-domain structure, and a quantity of electronic components is reduced based on improvement of color cast, and then an aperture ratio of a pixel is improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

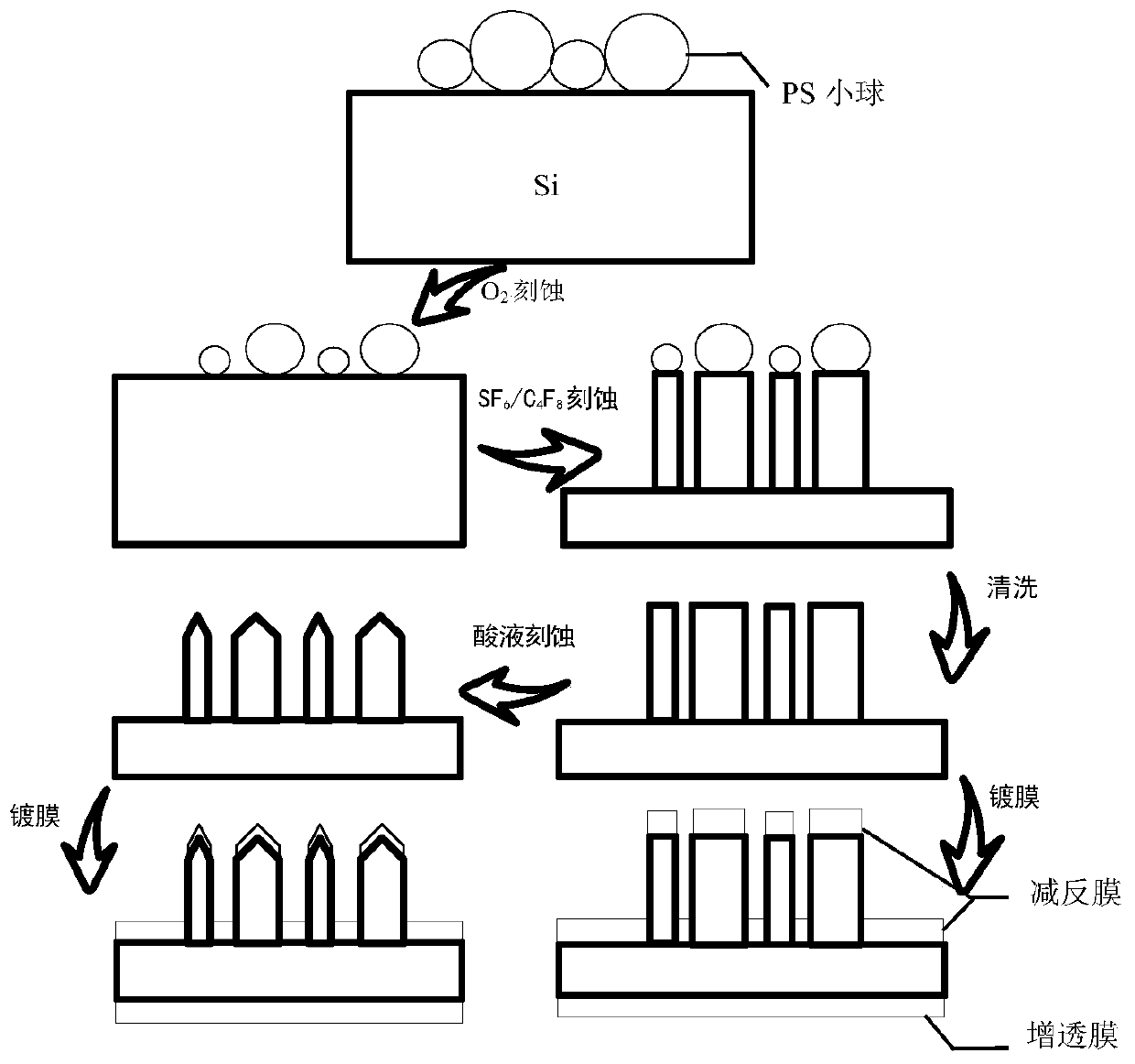

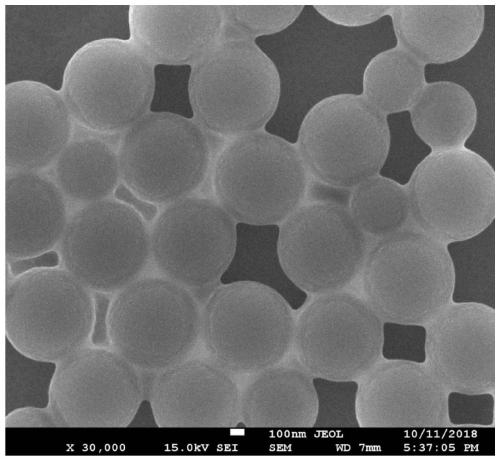

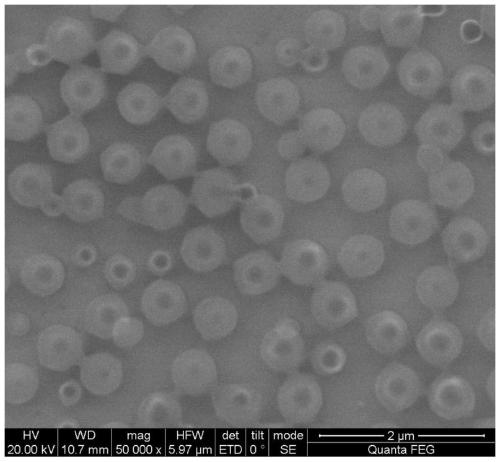

Monocrystalline silicon surface composite microstructure based on full-wave band anti-reflection and a preparation method thereof

ActiveCN109853044AOptimize structureImprove utilizationPolycrystalline material growthAfter-treatment detailsComposite microstructureSolar cell

The invention discloses a monocrystalline silicon surface composite microstructure based on full-band anti-reflection and a preparation method of the monocrystalline silicon surface composite microstructure. The preparation method comprises a part of or all of the following steps (1) - (4), and each step is executed for one or more times: (1) carrying out hydrophilic treatment on a silicon wafer,preparing a polystyrene sphere mixed solution, and paving a mask, polystyrene spheres, on the surface of the silicon wafer; (2) introducing oxygen for etching the wafer, and then introducing sulfur hexafluoride and octafluorocycloalkane for an etching-passivation-etching circulation to obtain monocrystalline silicon with a nano-pillar structure; (3) soaking the monocrystalline silicon with the nano-pillar structure into an acidic etching solution containing silver nitrate for surface corrosion to obtain monocrystalline silicon with a nano pencil-shaped structure; (4) carrying out magnetron sputtering on the monocrystalline silicon with the microstructure for plating an anti-reflection layer on the front surface, or the back surface or both, of the monocrystalline silicon. According to theinvention, the anti-reflection effect on full-band solar energy is effectively improved, so that the conversion efficiency of the solar cell is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

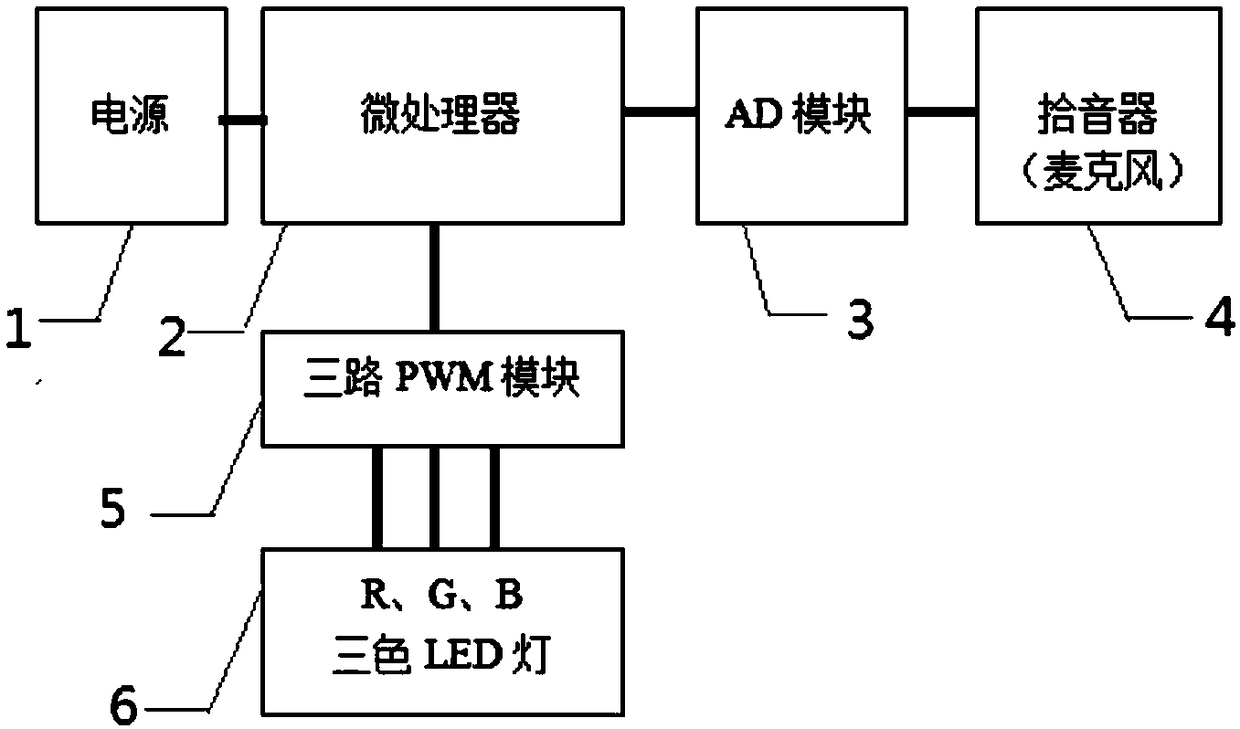

Pickup LED color modulation lamp

InactiveCN108135050AControl duty cycleRealize luminescence controlElectrical apparatusElectroluminescent light sourcesEnvironmental soundsFrequency spectrum

The invention discloses a pickup LED color modulation lap. The pickup LED color modulation lap comprises a power supply, a microprocessor, an AD module, a pickup device, a PWM control module and a RGBthree-color LED lamp, wherein the power supply is electrically connected with the microprocessor, the pickup device is in signal connection with the microprocessor by the AD module, and the microprocessor is in electric-control connection with the RGB three-color LED lamp via the PWM control module. The RGB color modulation LED lamp having a pickup function does not need a mobile phone and a network, the pickup device (a microphone) is designed, environmental sound is acquired, sound frequency spectrum is extracted by the processor, frequency spectrum information is used as a control parameter, a PWM duty ratio is controlled, light-emitting control of a RGB LED is achieved, and the purpose of color modulation is achieved. The pickup LED color modulation LED lamp can independently use, isnot dependent on other equipment and is simple to use, and color modulation can be achieved by acquiring the environmental sound (music playing or talking).

Owner:深圳市物联微电子有限公司

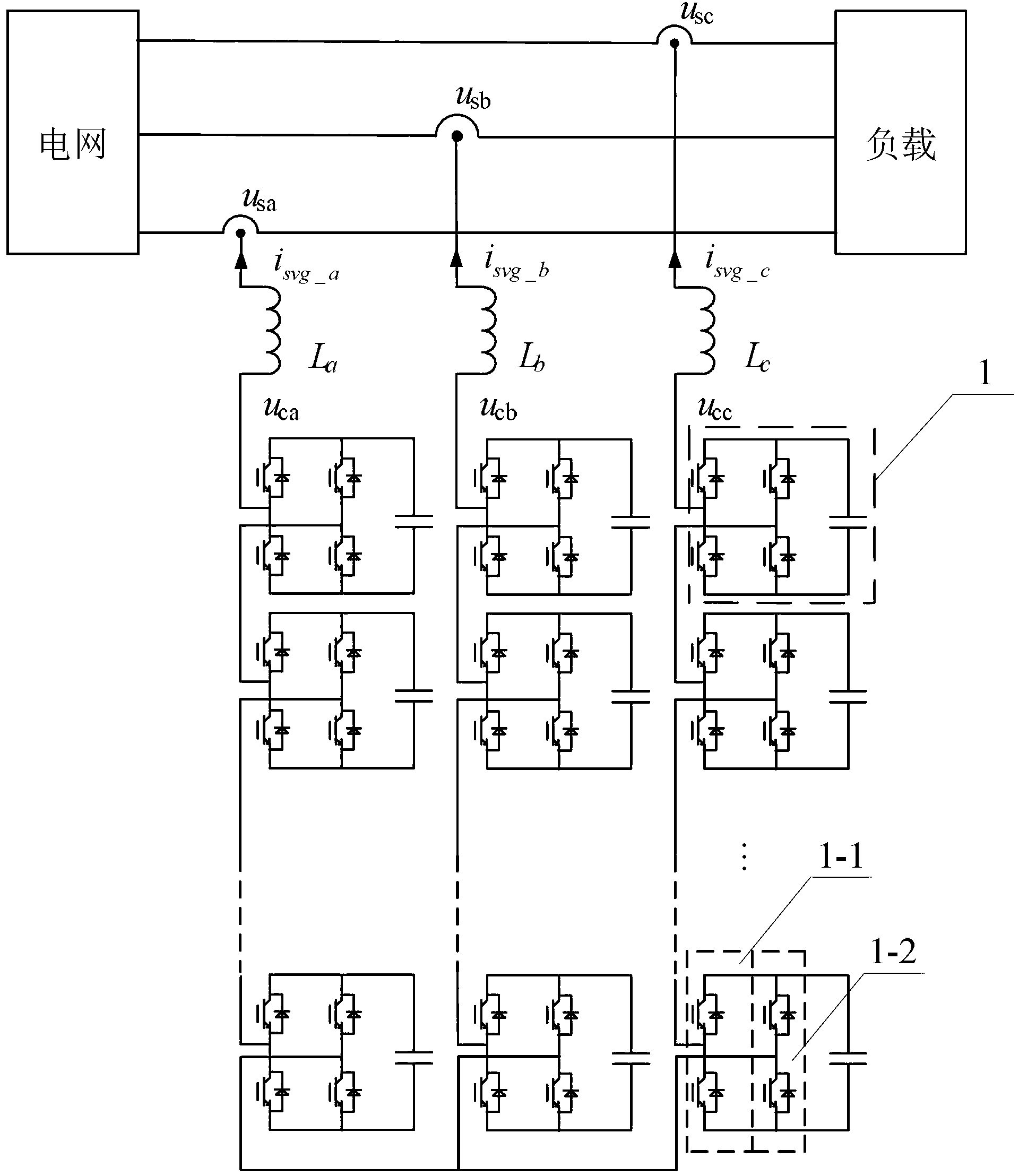

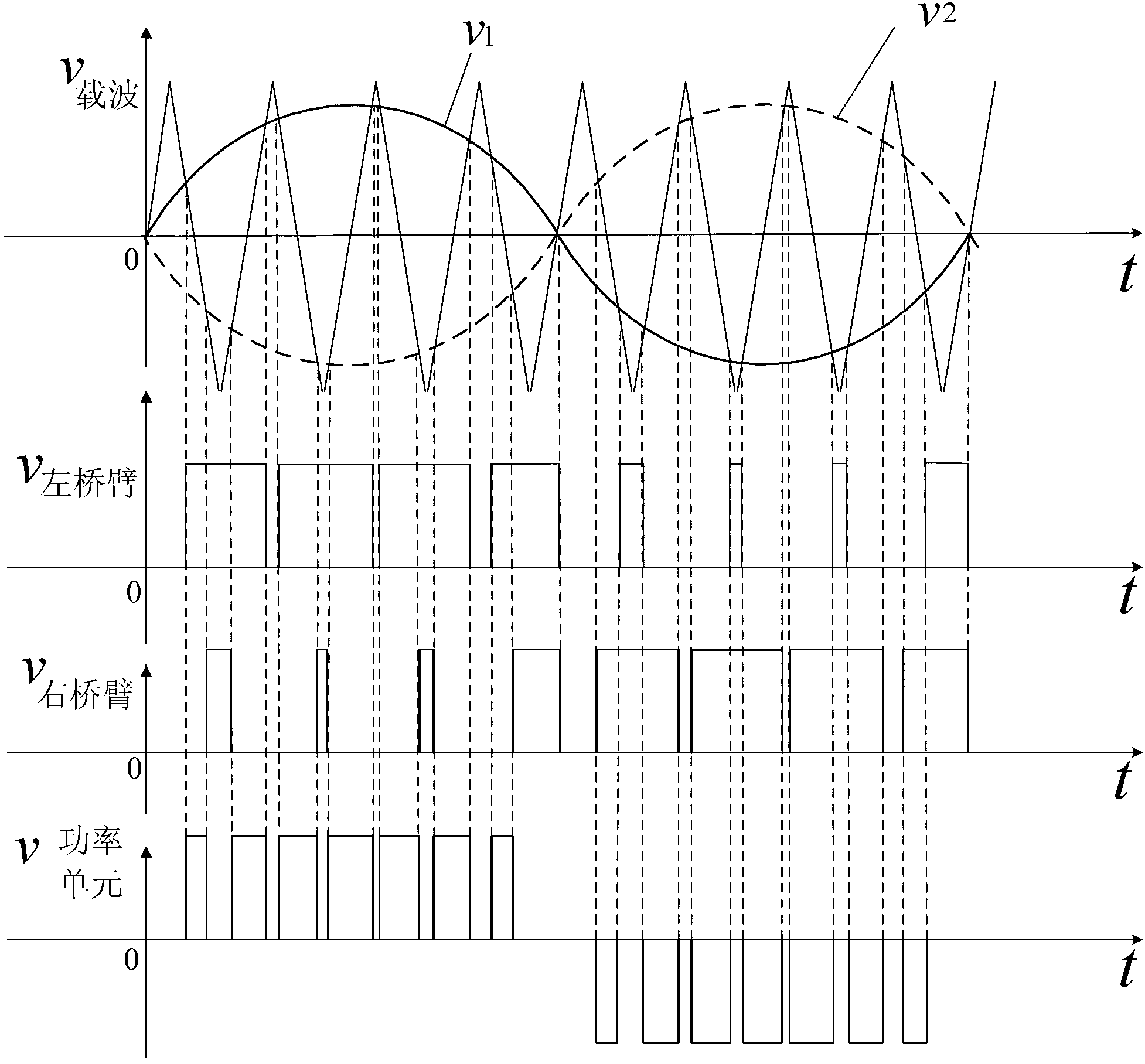

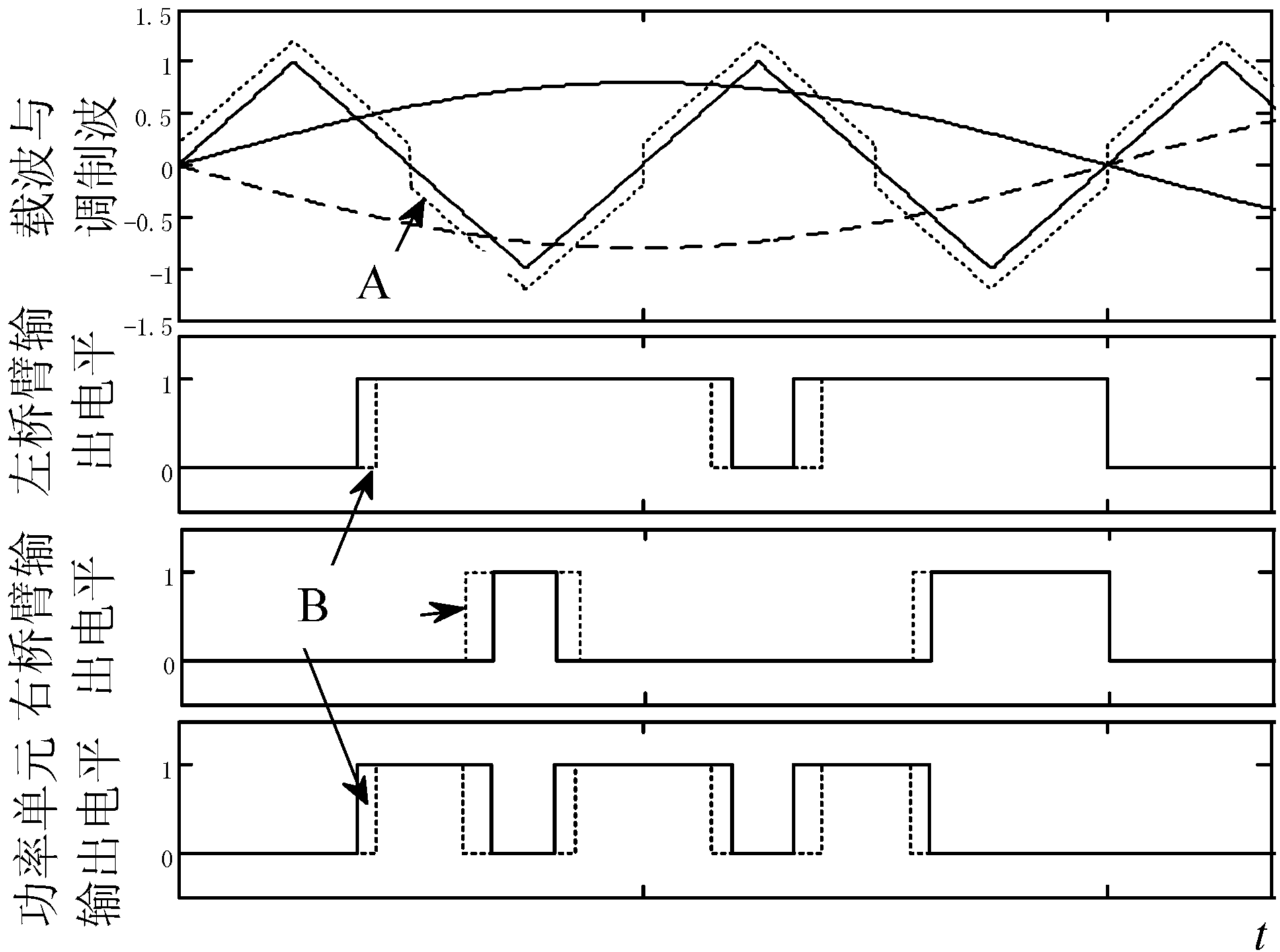

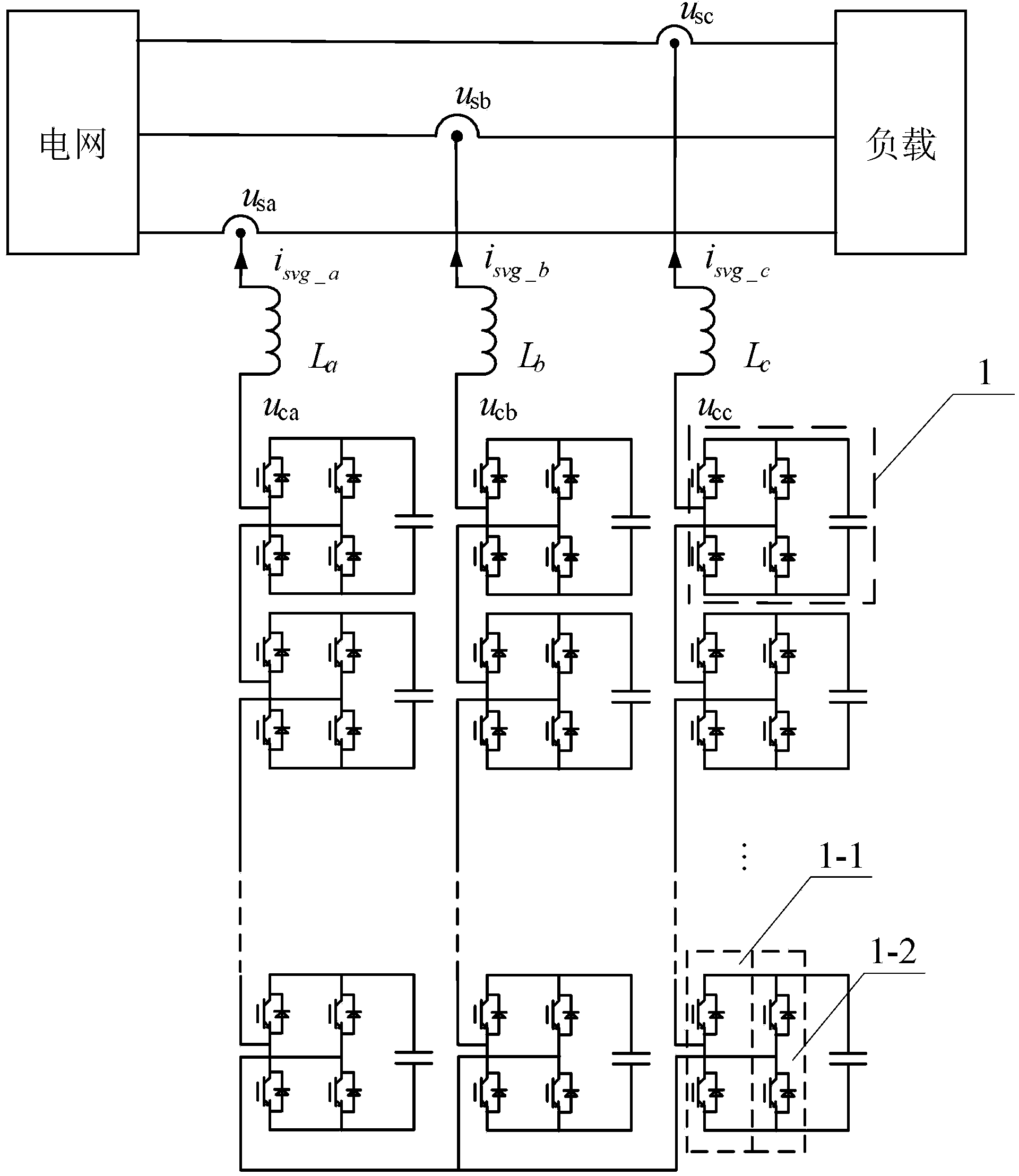

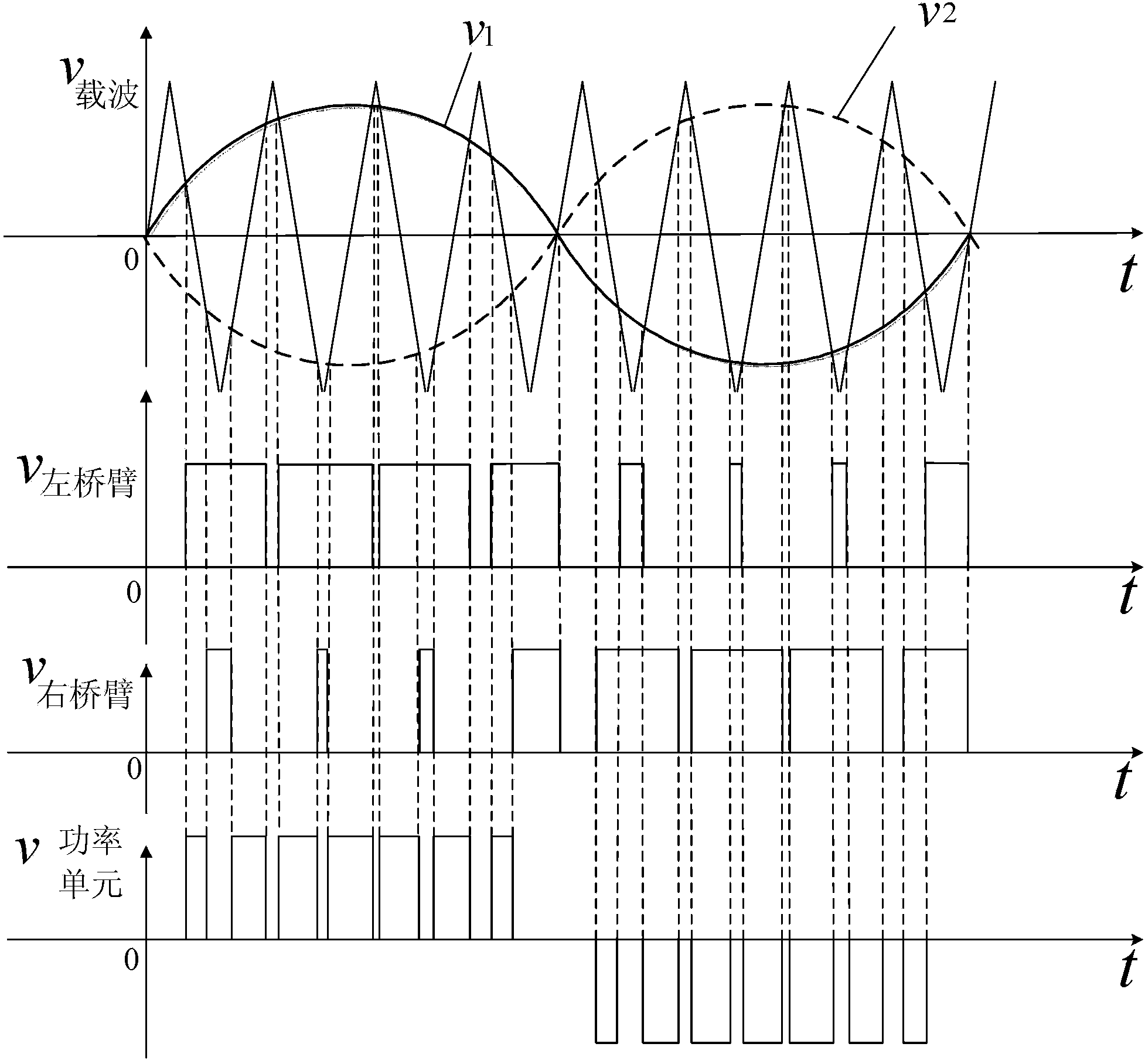

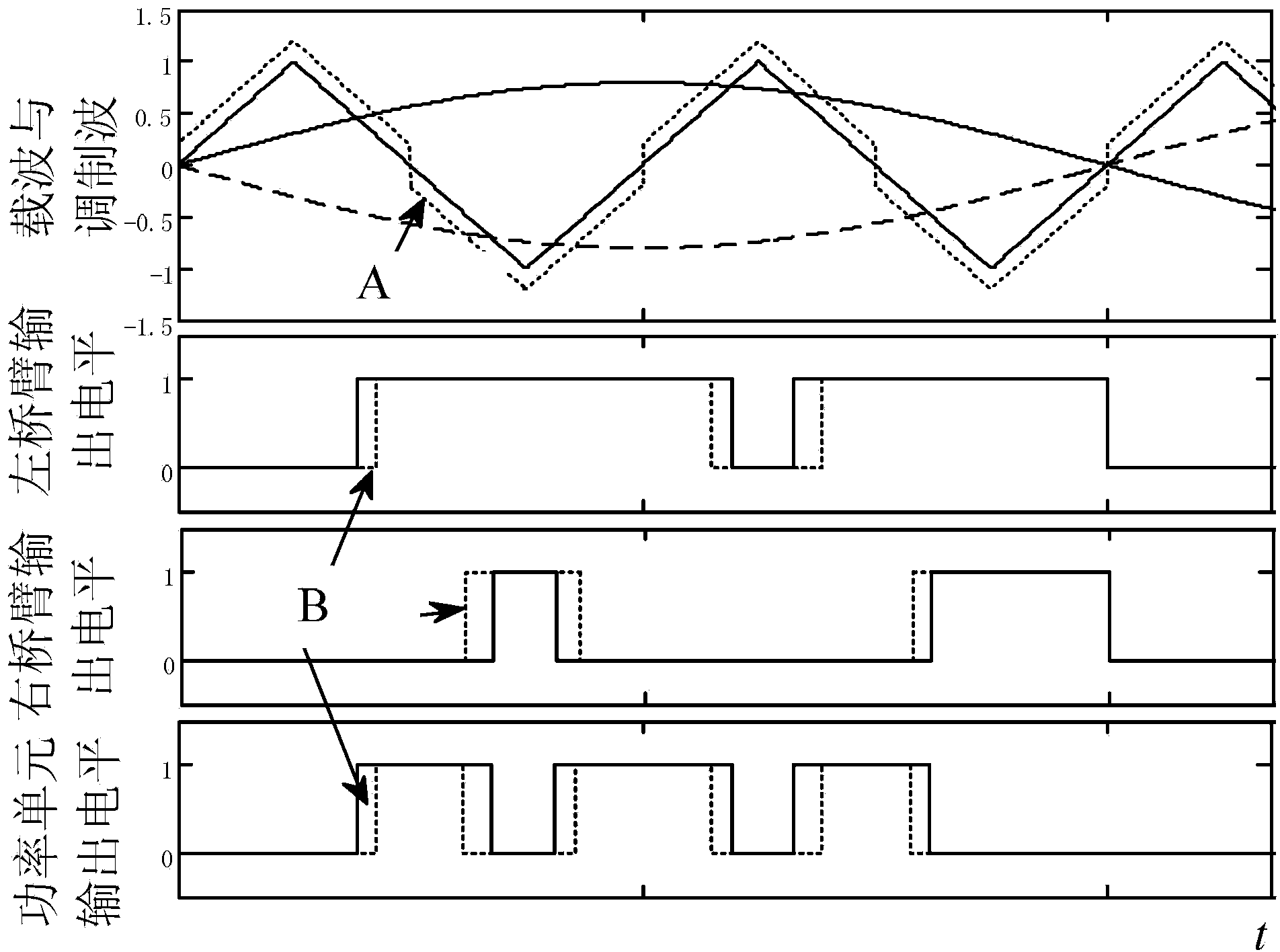

Capacitor voltage balance control method of cascade reactive power compensation device

InactiveCN103199550AControl capacitor voltageControl duty cycleReactive power adjustment/elimination/compensationReactive power compensationCarrier signalVoltage regulation

The invention provides a capacitor voltage balance control method of a cascade reactive power compensation device, belonging to the technical field of reactive power compensation control, and aiming at solving the problem that the existing method for balancing the capacitor voltage of a power unit is complex in process and unstable in control status. The method comprises the following steps of: firstly, acquiring the alternating current-side voltage u and the alternating current-side voltage i of each power unit in the cascade reactive power compensation device to obtain the instantaneous power polarity of each power unit; sampling the instantaneous capacitor voltage of a power unit by the frequency which is same as that of the carrier of the reactive power compensation device to obtain a voltage adjusting value of the power unit to be taken as a modification value of the carrier; confirming the modification value of the carrier and the overlapping mode of the carrier, and obtaining the adjusted carrier; and comparing the adjusted carrier with the sinusoidal modulation wave to obtain a modulating signal of the power unit, and controlling the power unit of the reactive power compensation device by the modulating signal to realize the capacitor voltage balance control of the compensation device. The capacitor voltage balance control method is used for balancing the capacitor voltage of the reactive compensation device.

Owner:HARBIN INST OF TECH

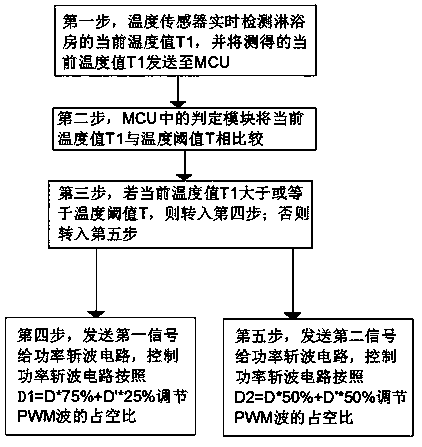

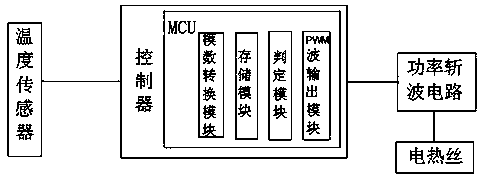

Intelligent bathroom heater temperature regulation method

InactiveCN108954483AImprove reliabilityHigh degree of intelligenceLighting and heating apparatusSpace heating and ventilation detailsElectric heatingEngineering

The invention relates to an intelligent bathroom heater temperature regulation method. The intelligent bathroom heater temperature regulation method includes the following steps that firstly, a temperature sensor detects the current temperature value T1 of a shower room in real time and sends the detected current temperature value T1 to an MCU; secondly, a judgment module in the MCU compares the current temperature value T1 with the temperature threshold value T; thirdly, if the current temperature value T1 is larger than or equal to the temperature threshold value T, the fourth step is executed, and if the current temperature value T1 is smaller than the temperature threshold value T, the fifth step is executed, wherein the fourth step and the fifth step are in no particular order; fourthly, a first signal is sent to a power chopper circuit, and therefore the power chopper circuit can be controlled and regulated to regulate the duty ratio of PWM waves according to a first empirical formula, and the heating temperature of electric heating wires is regulated; and fifthly, a second signal is sent to the power chopper circuit, and therefore the power chopper circuit can be controlledto regulate the duty ratio of the PWM waves according to a second empirical formula, and the heating temperature of the electric heating wires is regulated.

Owner:苏州妙文信息科技有限公司

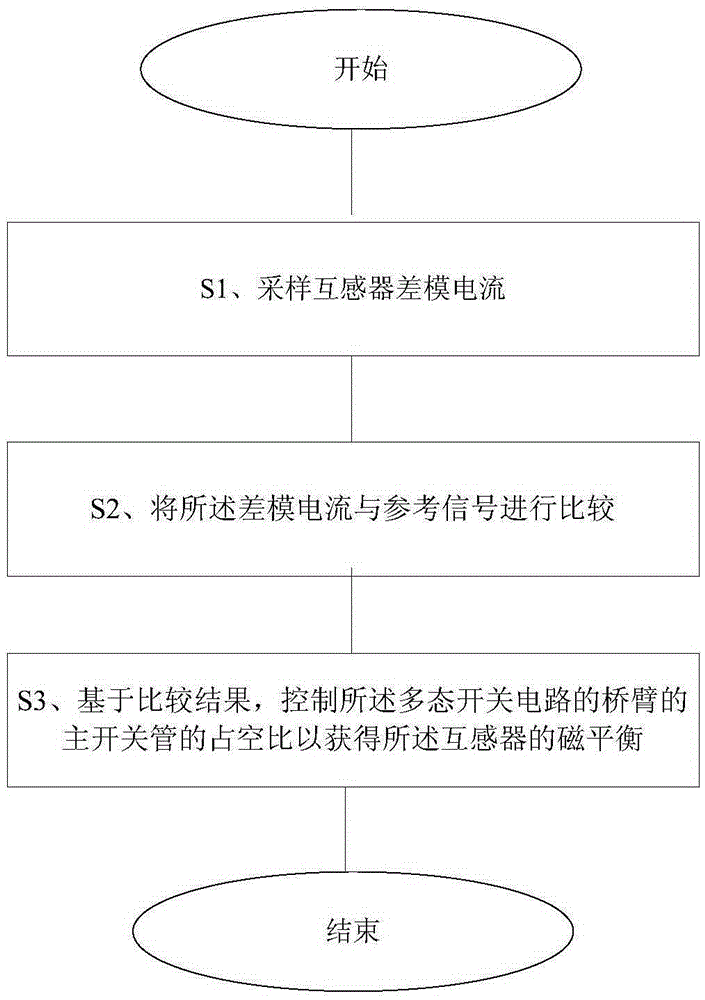

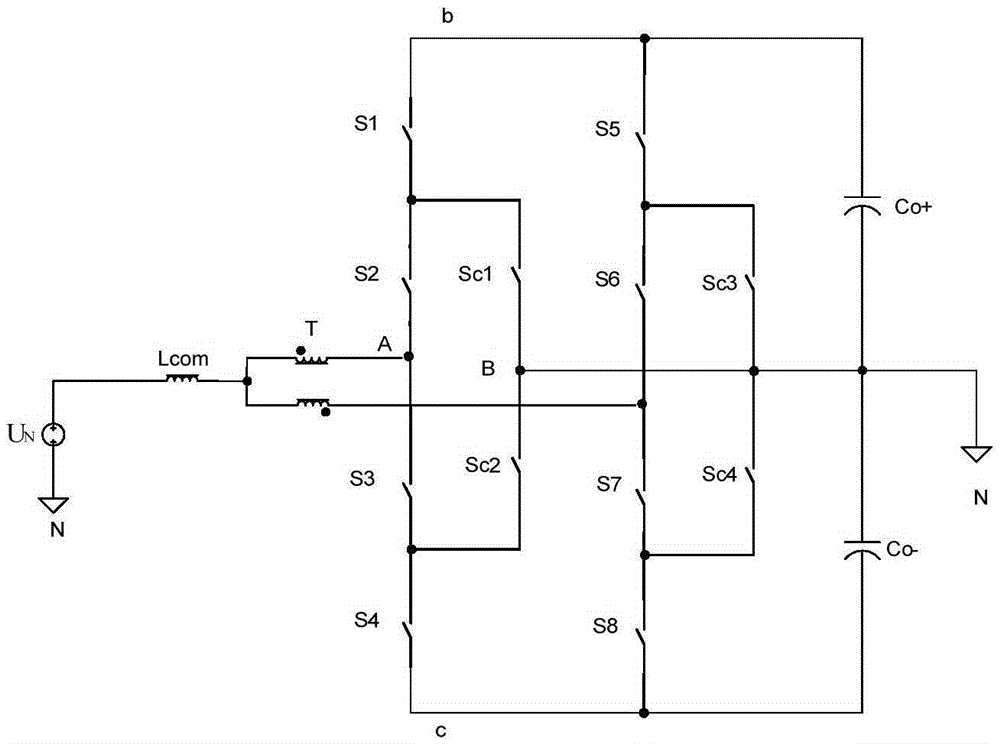

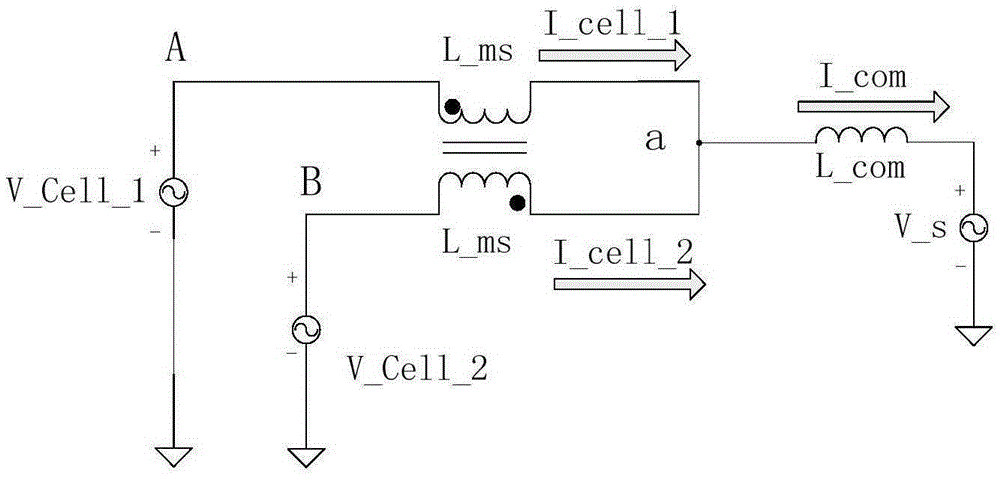

Mutual inductor magnetic balance method and device of multi-state switch circuit

ActiveCN106533150AMagnetic balance obtainedControl duty cyclePower conversion systemsInductorElectrical and Electronics engineering

The invention relates to a mutual inductor magnetic balance method of a multi-state switch circuit. The mutual inductor magnetic balance method comprises the steps of S1, sampling a difference mode current of a mutual inductor; S2, comparing the difference mode current with a reference signal; and S3, controlling duty cycle of a main switching tube of a bridge arm of the multi-state switch circuit according to a comparison result so as to acquire magnetic balance of the mutual inductor. By implementing the mutual inductor magnetic balance method and device of the multi-state switch circuit, the difference mode current of the mutual inductor is sampled, the duty cycle of the main switching tube of the bridge arm of the multi-state switch circuit is controlled, and thus, the magnetic balance of the mutual inductor can be further acquired.

Owner:VERTIV CORP

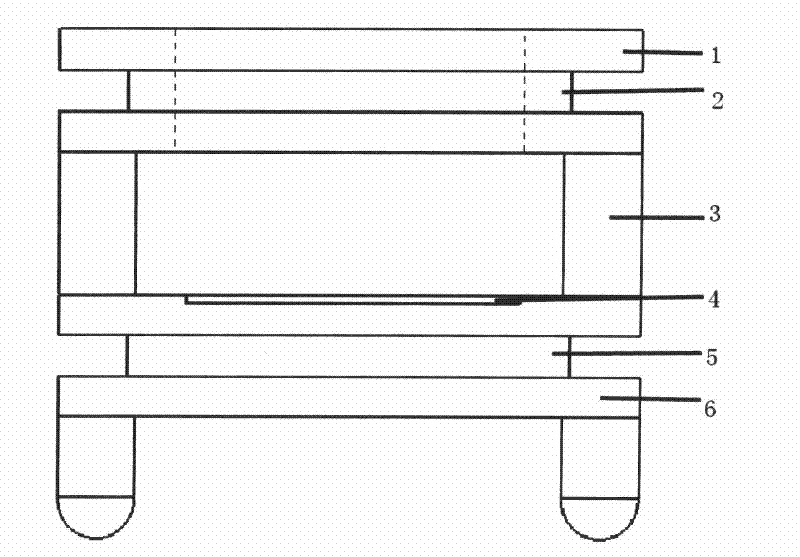

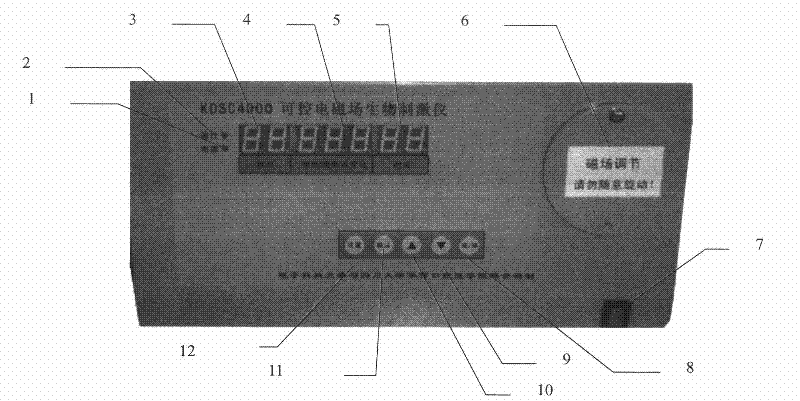

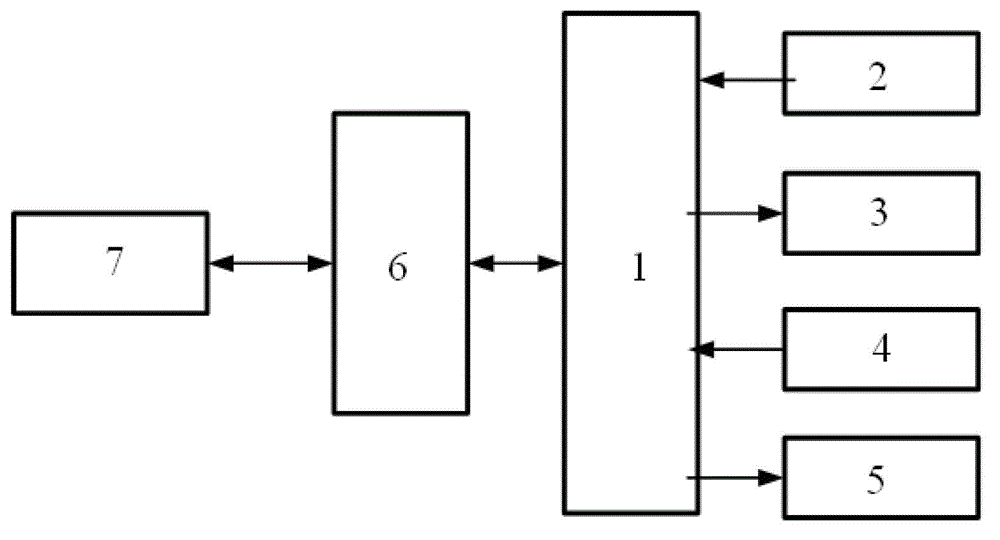

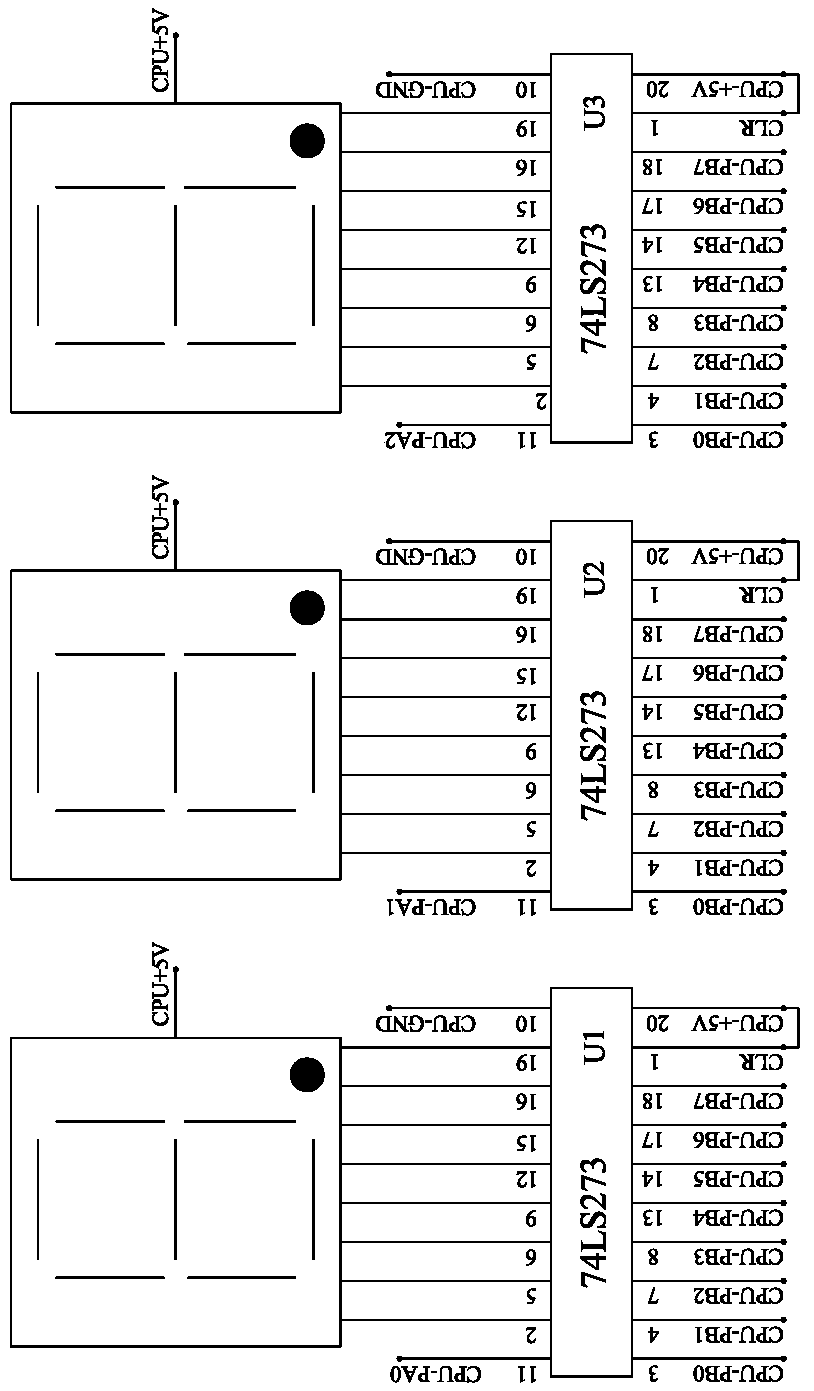

Fully adjustable electromagnetic field biological effect loading device and electromagnetic field loading method

InactiveCN102533545AControl electromagnetic field parametersSimple and fast operationStress based microorganism growth stimulationRadiation therapyControl powerEngineering

The invention discloses a fully adjustable electromagnetic field biological effect loading device and an in vivo and in vitro electromagnetic field loading method thereof. The device comprises a driving power supply (1), a driving unit (2), a magnetic field mechanism (3), a control power supply (4), a control unit (5) and a display unit (6), wherein the driving power supply (1) is connected with the driving unit (2) and the magnetic field mechanism (3); the driving unit (2) is directly connected with the magnetic field mechanism (3); the control power supply (4) is connected with the control unit (5) and the display unit (6); and the control unit (5) is connected with the driving unit (2) and the display unit (6).

Owner:SICHUAN UNIV +1

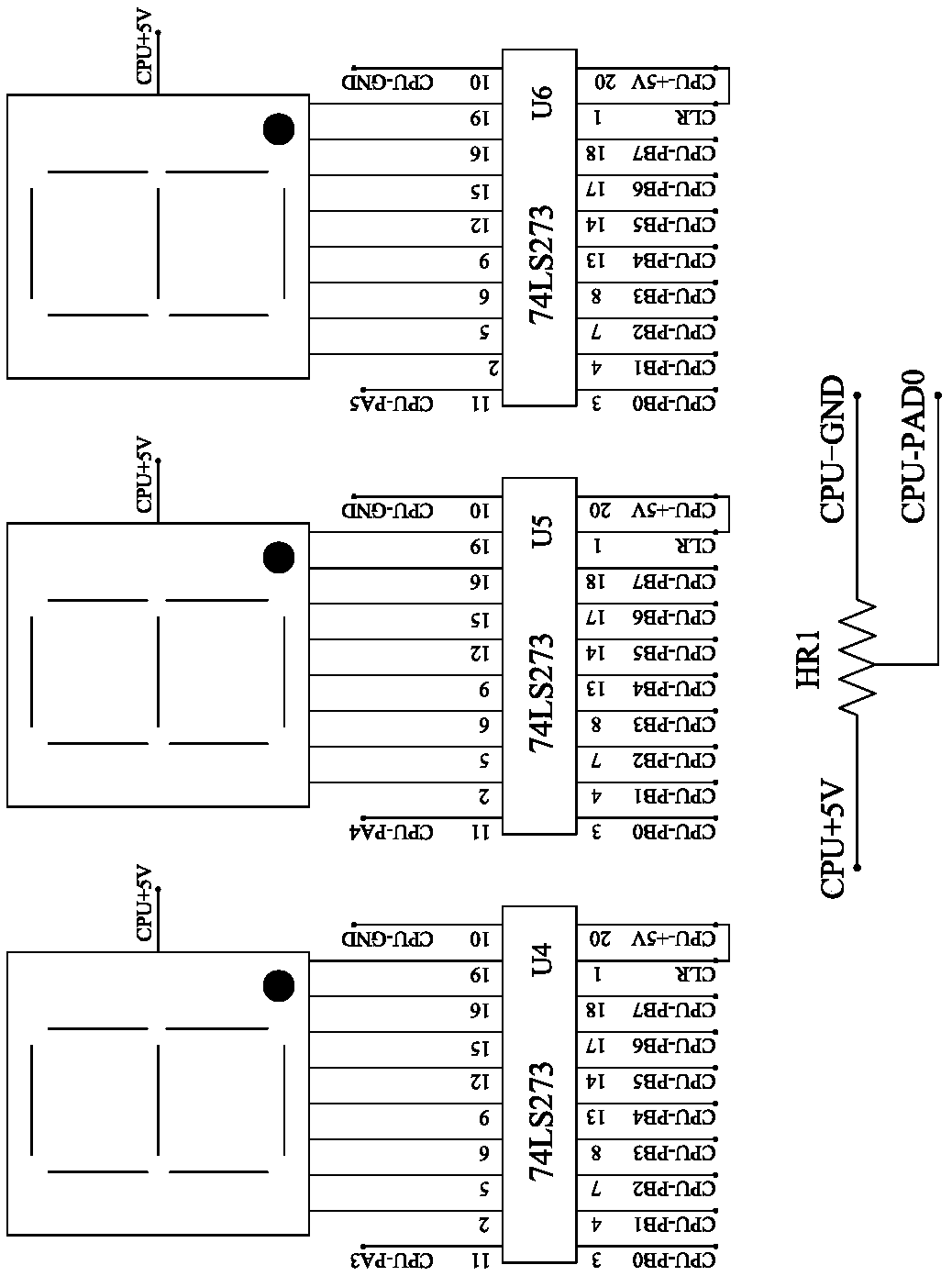

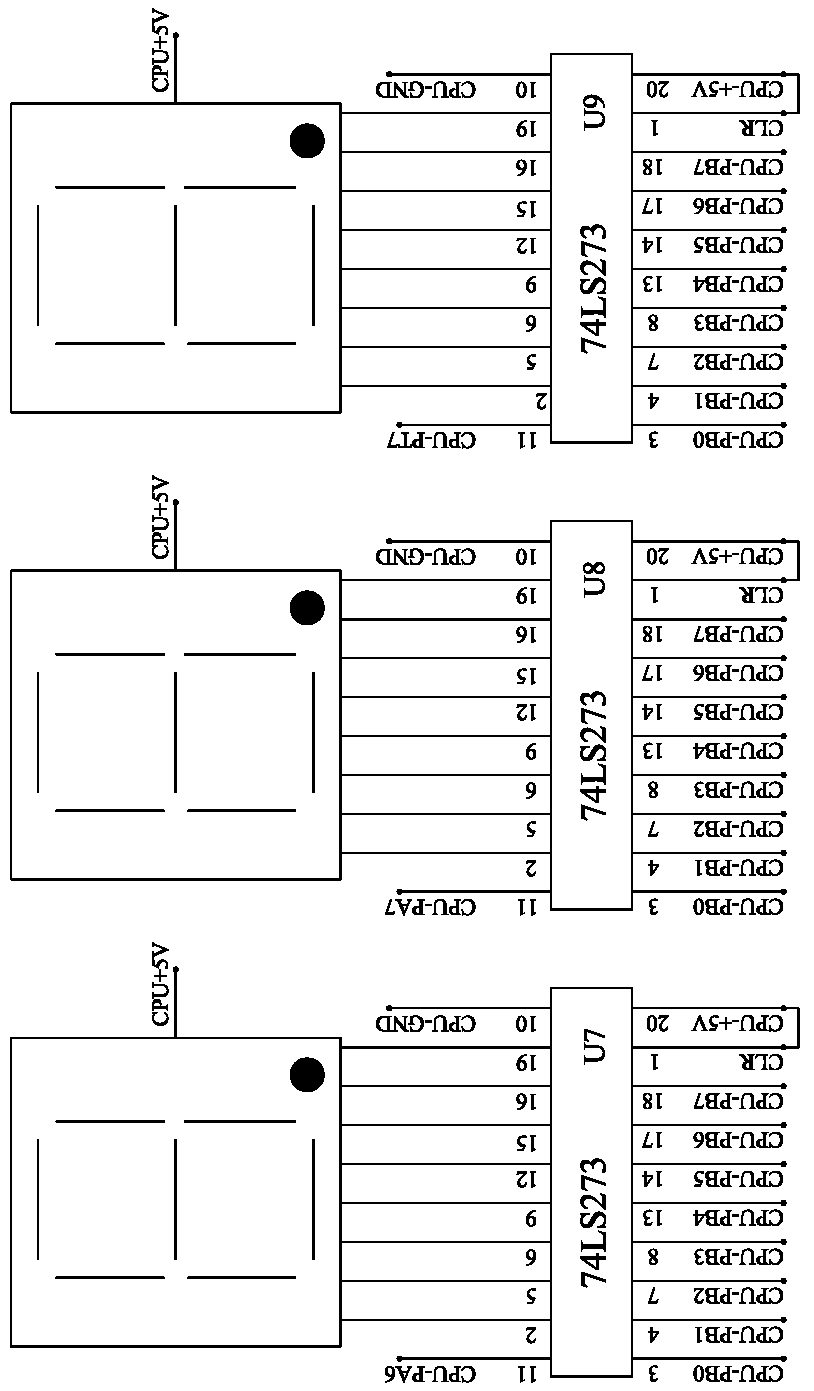

Clock system

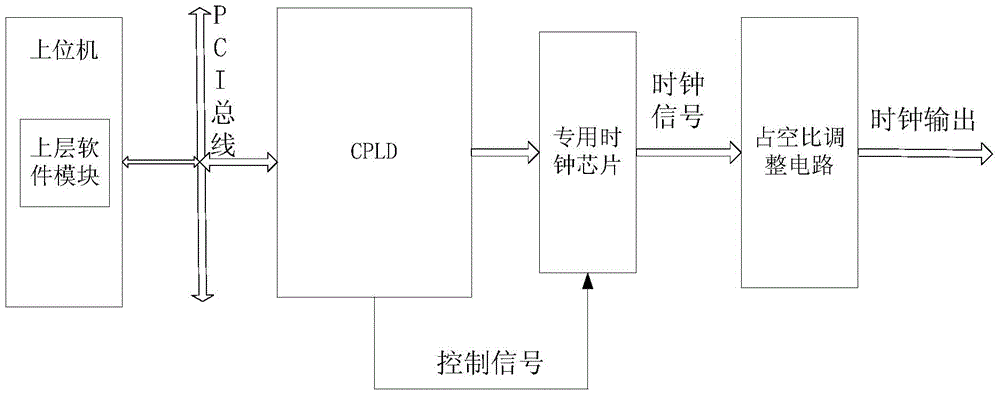

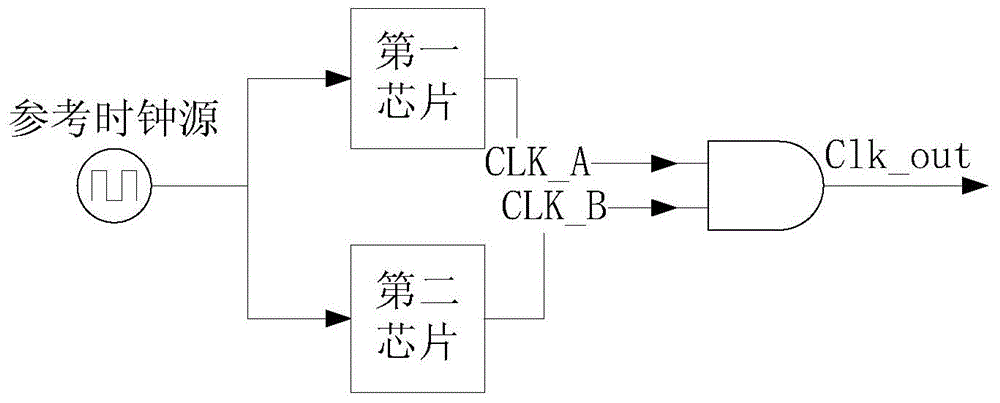

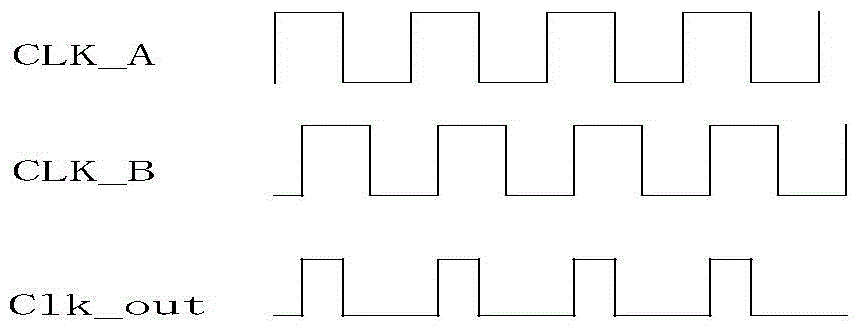

InactiveCN104866008AWide clock output rangeHigh resolutionGenerating/distributing signalsElectronic systemsSystem requirements

The present invention relates to the technical field of electronics, in particular to a clock system used in an electronic system. The clock system comprises: a host computer, connected to a PCI bus and used for setting a frequency of a clock that needs to be output and choosing a corresponding channel, wherein the host computer is provided with an upper-layer software module that is connected to the PCI bus and that is used for calculating a value of a control register of a dedicated clock chip according to the frequency, set by the host computer, of the clock that needs to be output; CPLD, connected to the PCI bus and used for acquiring the value of the control register and sending the value of the control register to the dedicated clock chip; and the dedicated clock chip, used for generating a corresponding clock signal according to the value of the control register and outputting the corresponding clock signal. According to the above technical scheme of the present invention, the output clock frequency can be set by the host computer, the clock output range is super wide, and the resolution is high. According to the present invention, a duty cycle of the output clock can also be controlled, thereby meeting system requirements on the duty cycle.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

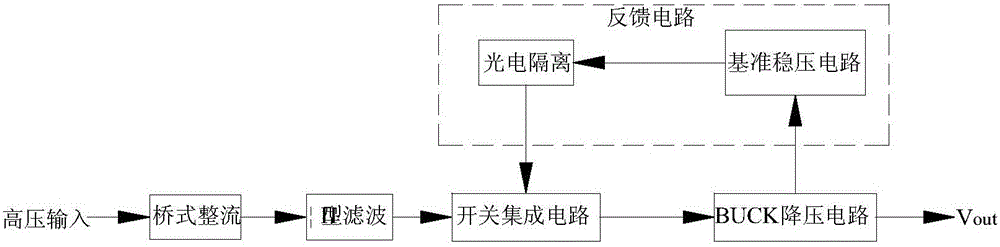

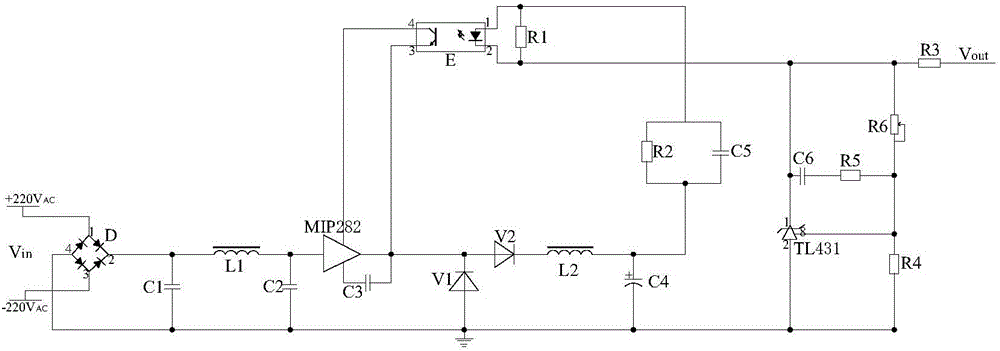

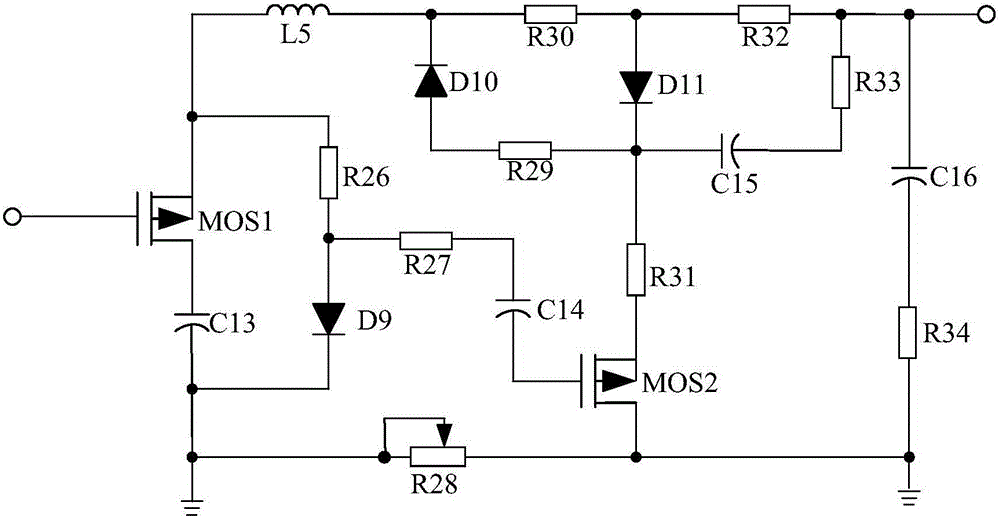

Input-output common ground based high-voltage adjustable step-down circuit

InactiveCN105932892AHigh voltage regulation accuracySimple circuit structureAc-dc conversionDc-dc conversionSignal onIntegrated circuit

The invention discloses an input-output common ground based high-voltage adjustable step-down circuit. A high-voltage alternating current or a high-voltage direct current of a high-voltage input end enters a switch integration circuit through bridge rectification and pi filtering; the switch integration circuit is connected with a typical BUCK step-down circuit; a voltage stabilization reference circuit provides a voltage stabilization reference voltage and turns on a photoelectric isolator; the photoelectric isolator provides a feedback voltage; and the photoelectric isolator is used for feedback isolation between a high-voltage input and a low-voltage output, so that the interference of a high-voltage-side signal on a low-voltage-side signal is reduced. The high-voltage direct current or alternating current is converted into a low-voltage direct current; a resistance value of a slide rheostat is changed to obtain different low-voltage direct-current voltages; and the high-voltage adjustable step-down circuit can be widely applied to step-down circuits of high-voltage switches, especially certain instrument devices with requirements of converting commercial power into a direct-current low-voltage adjustable power supply.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

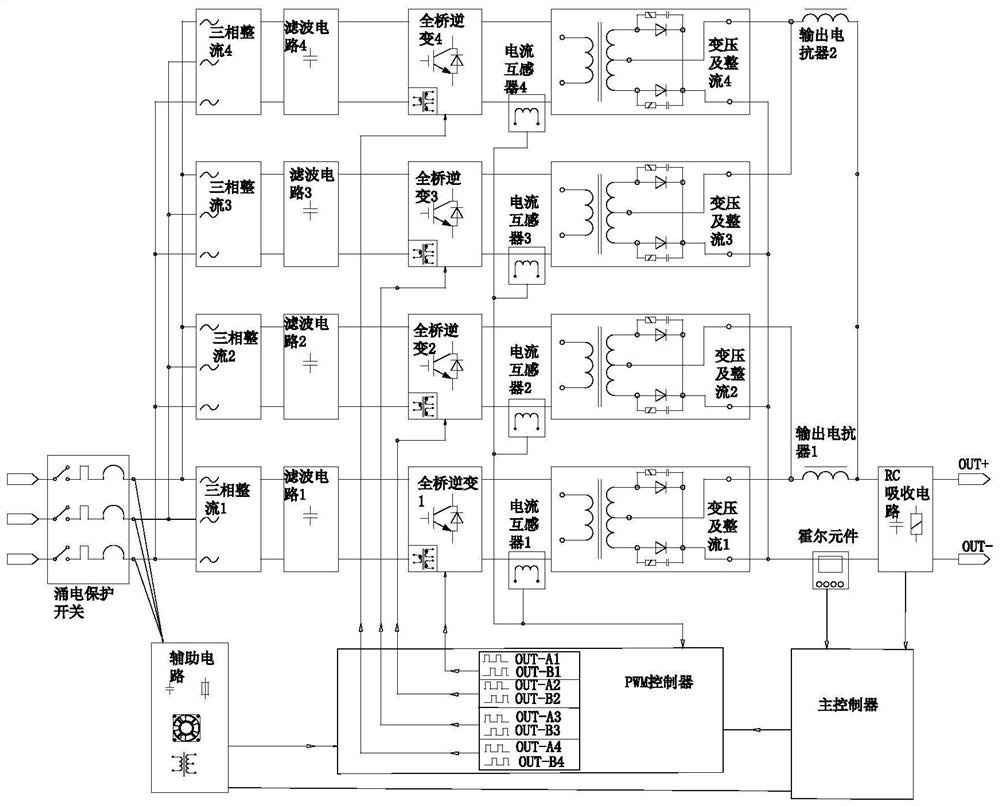

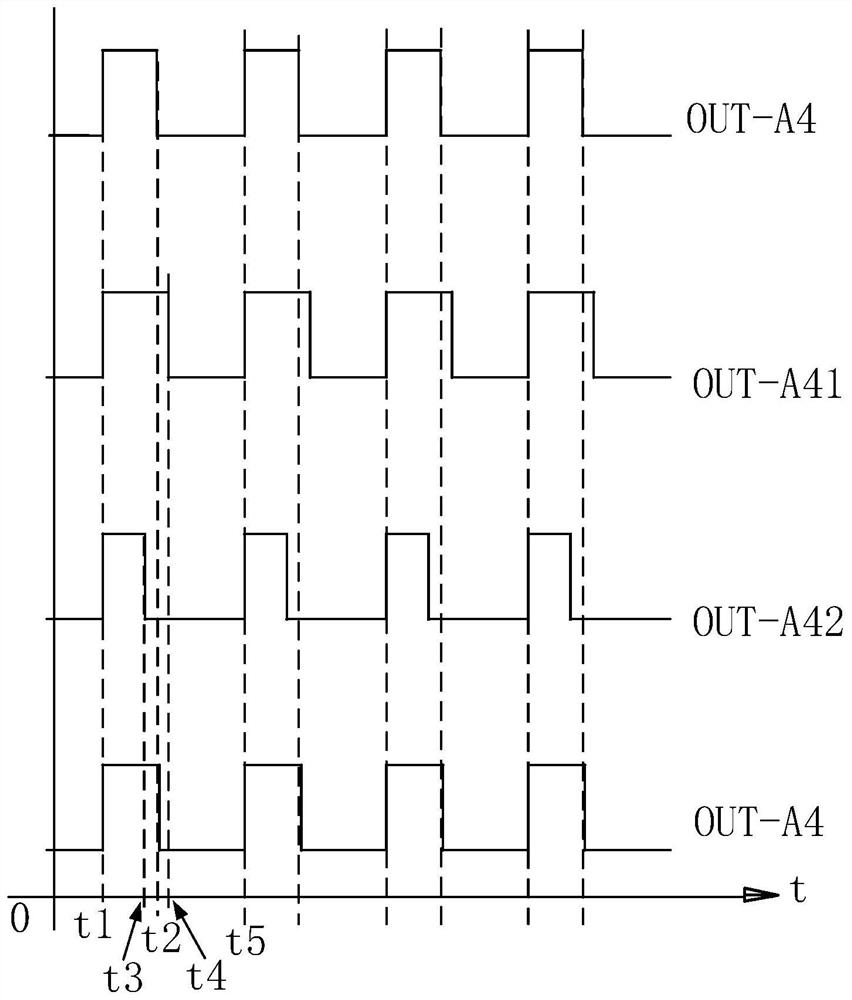

Four-group parallel inverter welding power supply control method and circuit

PendingCN112828424AOutput current balanceControl duty cycleArc welding apparatusControl signalFull bridge

The invention discloses a four-group parallel inverter welding power supply control method and circuit. The four-group parallel inverter welding power supply comprises a main controller, a PWM controller and four groups of inverter sub-power supplies connected in parallel, wherein each inverter sub-power supply comprises a three-phase rectification circuit, a filter circuit, an IGBT full-bridge inverter circuit, a transformation and rectification circuit and a current detection circuit which are connected in sequence; the PWM controller outputs four groups of independent PWM control signals to the four groups of IGBT full-bridge inverter circuits respectively; rising edges of the four paths of PWM control signals are synchronous; output current of each inverter sub-power supply is detected; the output current of each inverter sub-power supply is compared with a current set value; the output currents of the inverter sub-power supplies are compared; and the turn-off time of the falling edge of each PWM signal is controlled, the duty ratio of the PWM signal of the inverter sub-power supply with large output current is reduced, the duty ratio of the PWM signal of the inverter sub-power supply with small output current is increased, the output currents of the inverter sub-power supplies are equal, and the reliability of the welding power supply is improved.

Owner:SHANGHAI HUGONG ELECTRIC WELDING MACHINE MFG

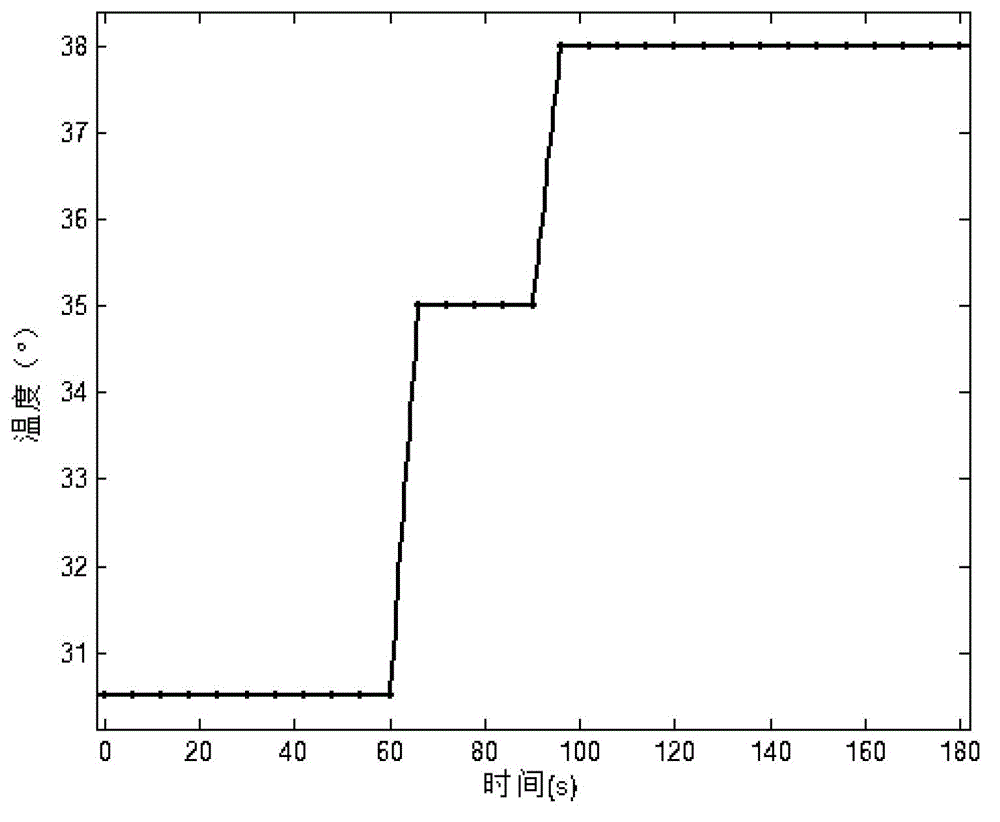

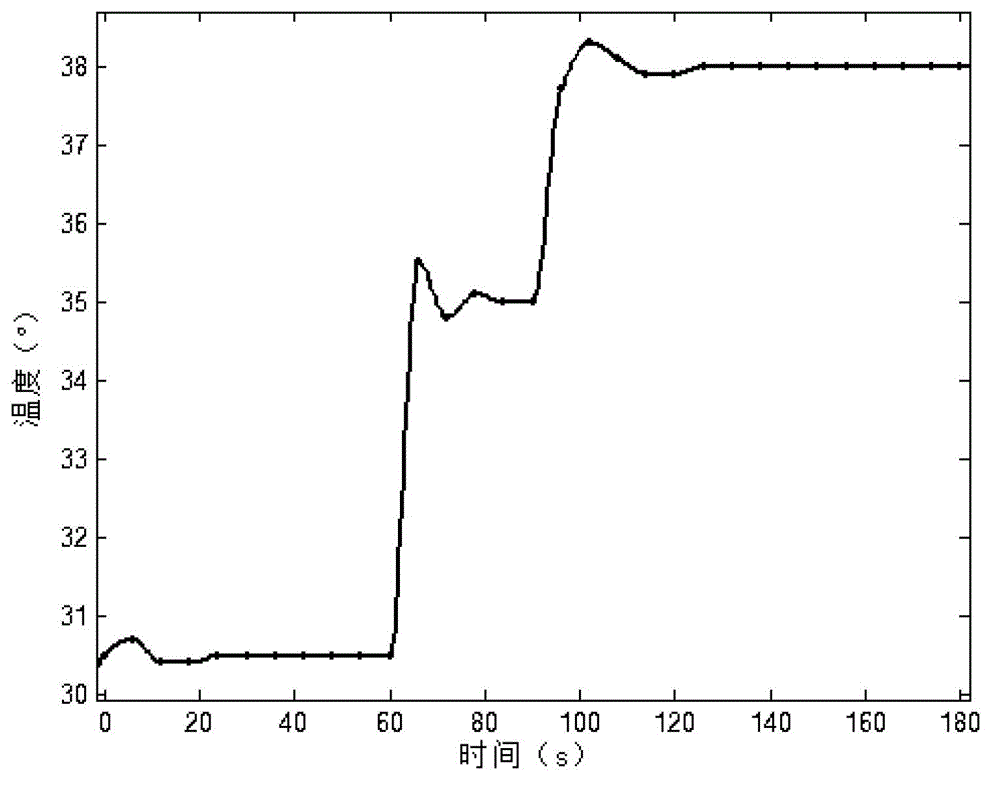

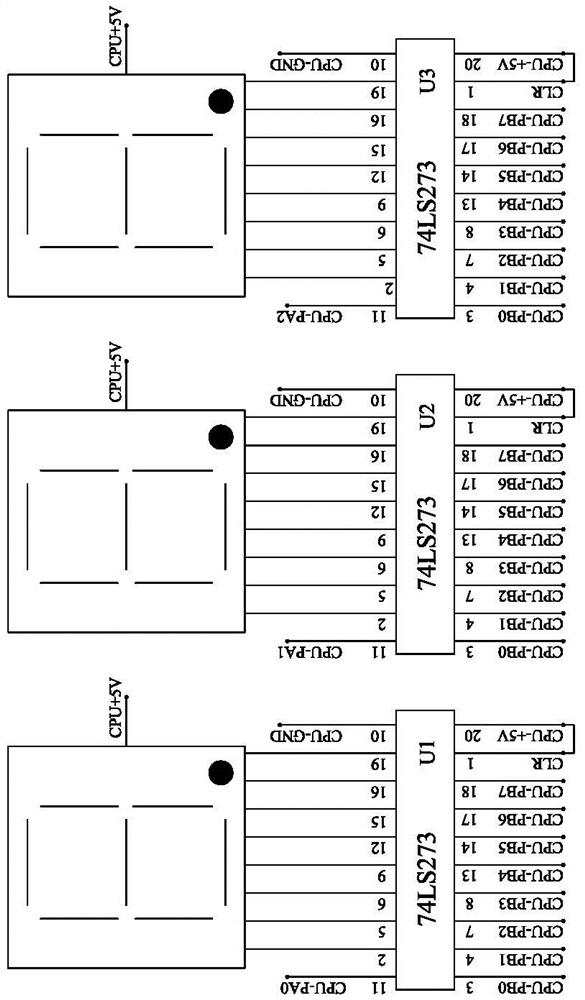

Temperature control system

InactiveCN103279155BIncrease the level of automationRealize temperature gradient change controlAuxillary controllers with auxillary heating devicesInteractive softwareTemperature control

The invention discloses a temperature control system, which comprises a lower computer and an upper computer, wherein the lower computer consists of an automatic voltage regulation (AVR) single chip microcomputer, a temperature sensor, a light-emitting diode (LED) display, a temperature setting circuit and a temperature heating circuit; and the upper computer consists of a personal computer (PC) and interactive software. According to the system, temperature and time for keeping the temperature can be input to the upper computer according to a temperature curve required by a user, the lower computer controls the gradience of the temperature and the system can meet requirements of users on different temperatures at different moments, responds sensitively and has higher accuracy.

Owner:CHANGAN UNIV

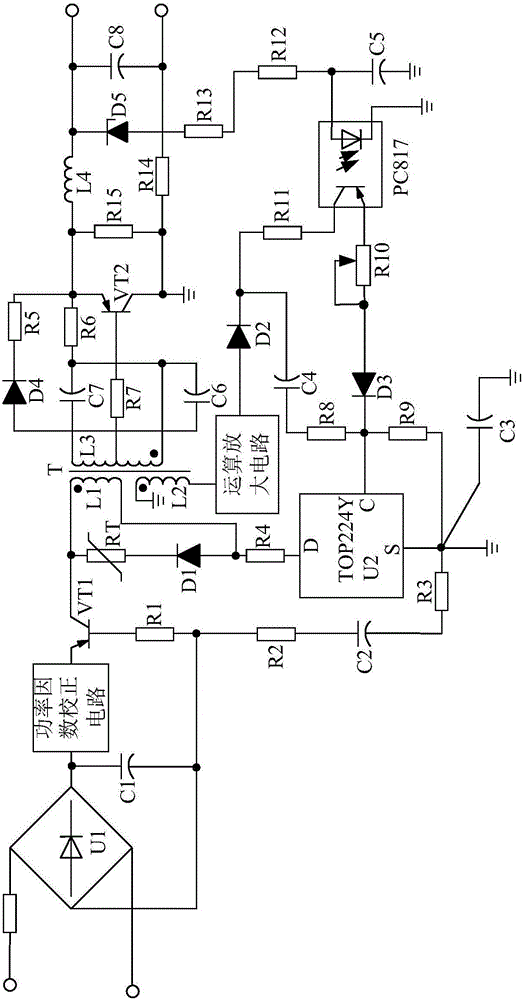

Flyback light emitting diode (LED) switching voltage stabilization driving power supply based on power factor correction circuit

InactiveCN106102211AImprove power factorReduce power consumptionElectrical apparatusElectroluminescent light sourcesDiode rectifierPower flow

The invention discloses a flyback light emitting diode (LED) switching voltage stabilization driving power supply based on a power factor correction circuit. The flyback LED switching voltage stabilization driving power supply is characterized by mainly comprising a control chip U2, a diode rectifier U1, an operational amplifier, a transformer T, a triode VT1, a diode D1, a primary flyback circuit, the power factor correction circuit and a constant current driving circuit, wherein the power factor correction circuit is connected in series between a negative electrode output end of the diode rectifier U1 and an emitter of the triode VT1, and the constant current driving circuit is connected with the transformer T and the primary flyback circuit separately. By the flyback LED switching voltage stabilization driving power supply, a current peak can be controlled to be constant, meanwhile, the switching duty ratio is controlled, the time proportion of the whole switching period is maintained and output constantly, so that constant output current is achieved; and moreover, the flyback LED switching voltage stabilization driving power supply only requires 0.5-microampere starting current, the starting power consumption is reduced, the efficiency of the flyback LED switching voltage stabilization driving power supply is greater than 80%, the no-load power consumption is smaller than 30mW, and thus, the efficiency of the flyback LED switching voltage stabilization driving power supply is improved.

Owner:CHENGDU JUHUICAI TECH

Capacitor voltage balance control method of cascade reactive power compensation device

InactiveCN103199550BControl capacitor voltageControl duty cycleReactive power adjustment/elimination/compensationReactive power compensationPower compensationCapacitor voltage

Owner:HARBIN INST OF TECH

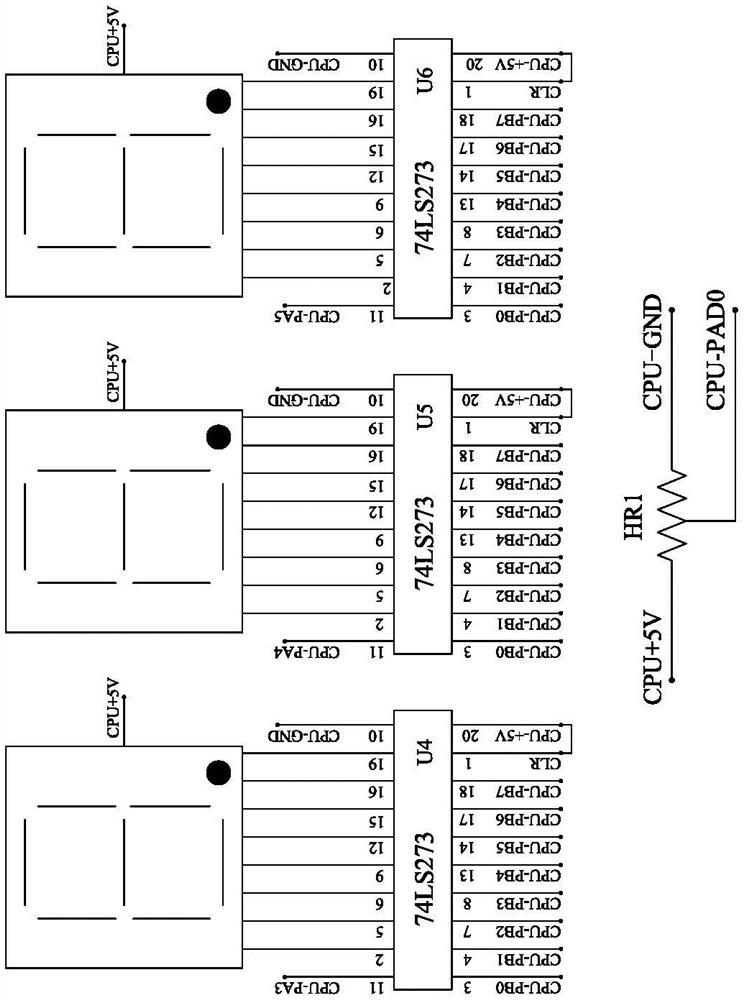

A step-down dc-dc conversion circuit for electric vehicles

ActiveCN110601534BMeet the rated voltage requirementsControl duty cycleBatteries circuit arrangementsDc-dc conversionConvertersPower battery

The invention relates to a step-down DC-DC conversion circuit for an electric vehicle. The step-down DC-DC conversion circuit comprises an output voltage value control circuit, the pulse width modulation signal output end of a CPU of the output voltage value control circuit is connected with the input end of an optocoupler, the output end of the optocoupler is connected with the control pulse input end of a drive module, and the drive pulse output end of the drive module is connected with grids of IGBTs. The collector of each IGBT is connected with the positive electrode of the power battery,and the load is connected between the emitter of each IGBT and the negative electrode of the power battery; and a plurality of load fly-wheel diodes which are connected in parallel are connected between the emitting electrode of each IGBT and the negative electrode of the power battery. A +5V power supply is generated by the power battery through the DC-DC converter to be used by the CPU, and a +15V power supply is generated to be used by the driving module. The circuit is further provided with an input voltage value display circuit, an output voltage setting and display circuit and an actualoutput voltage value display circuit. A low-voltage storage battery does not need to be installed, the installation space of the automobile is saved, the purchasing and battery replacing cost is saved, and operation is reliable.

Owner:南京丁博控制器有限公司

Step-down DC-DC conversion circuit for electric vehicle

ActiveCN110601534AMeet the rated voltage requirementsControl duty cycleBatteries circuit arrangementsDc-dc conversionPower batteryDc dc converter

The invention relates to a step-down DC-DC conversion circuit for an electric vehicle. The step-down DC-DC conversion circuit comprises an output voltage value control circuit, the pulse width modulation signal output end of a CPU of the output voltage value control circuit is connected with the input end of an optocoupler, the output end of the optocoupler is connected with the control pulse input end of a drive module, and the drive pulse output end of the drive module is connected with grids of IGBTs. The collector of each IGBT is connected with the positive electrode of the power battery,and the load is connected between the emitter of each IGBT and the negative electrode of the power battery; and a plurality of load fly-wheel diodes which are connected in parallel are connected between the emitting electrode of each IGBT and the negative electrode of the power battery. A +5V power supply is generated by the power battery through the DC-DC converter to be used by the CPU, and a +15V power supply is generated to be used by the driving module. The circuit is further provided with an input voltage value display circuit, an output voltage setting and display circuit and an actualoutput voltage value display circuit. A low-voltage storage battery does not need to be installed, the installation space of the automobile is saved, the purchasing and battery replacing cost is saved, and operation is reliable.

Owner:南京丁博控制器有限公司

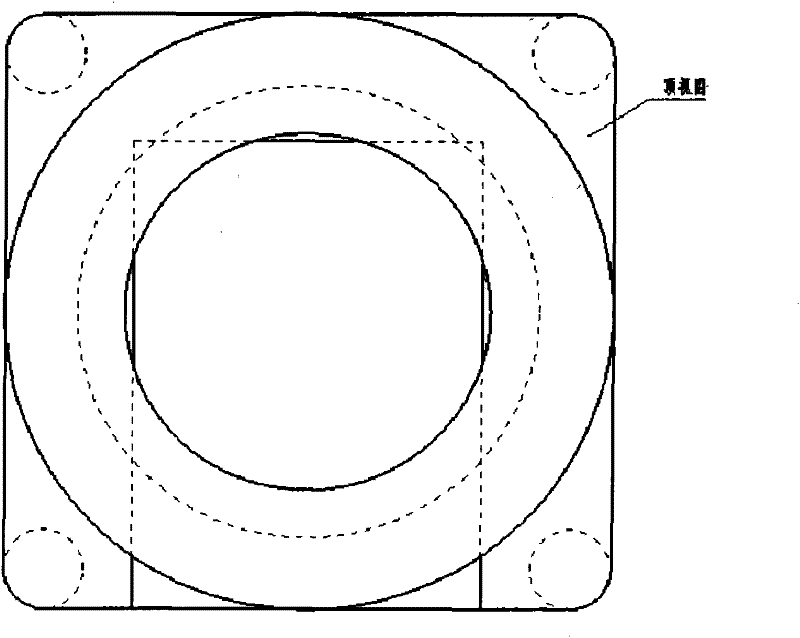

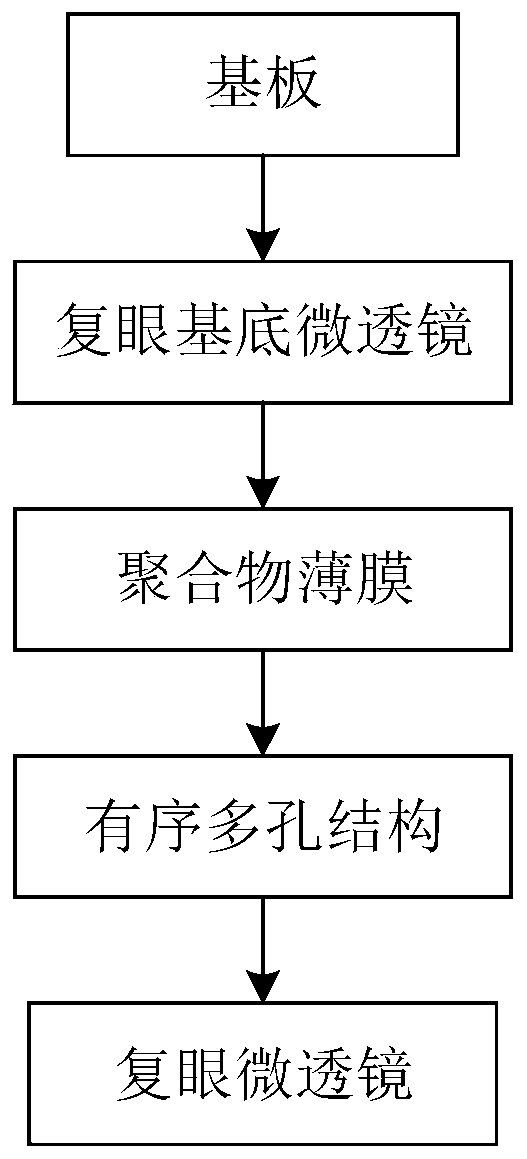

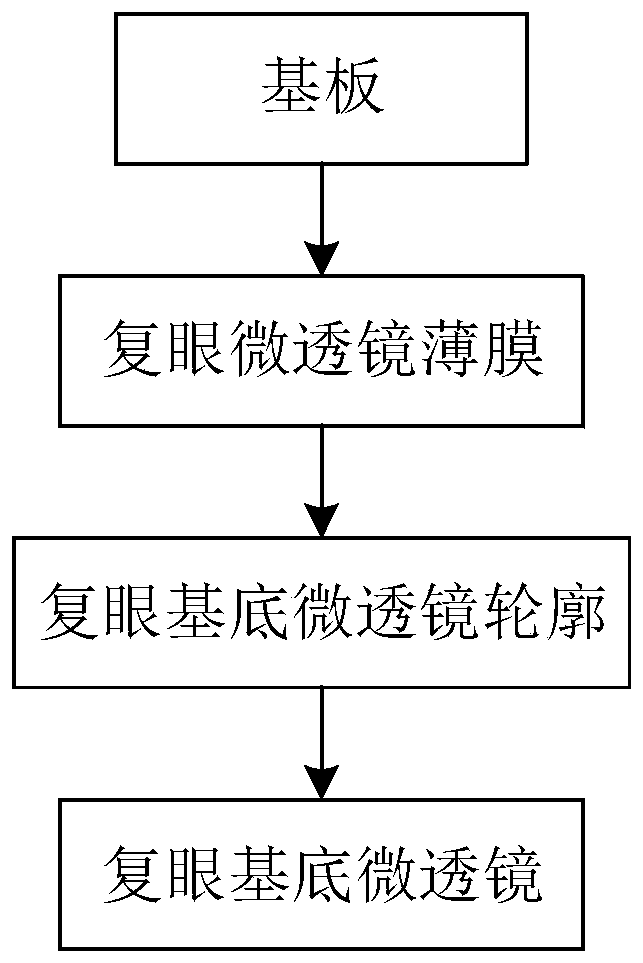

A compound eye microlens array and its preparation method

The invention belongs to the field of compound eye micro-lenses and discloses a compound eye micro-lens array and a preparation method thereof, the preparation method comprises the following steps: preparing a compound eye substrate micro-lens array on a clean substrate; then dissolving the polymer in a volatile solvent to prepare a polymer solution, pouring the polymer solution on a substrate with a compound eye substrate microlens array, and forming a layer of uniform polymer film through spin coating; and placing the substrate in a closed container and standing for a period of time, obtaining a three-dimensional honeycomb-shaped ordered porous structure on the surface of the compound eye substrate microlens array after the solvent is completely volatilized, and preparing the compound eye microlens and further to make the compound eye microlens array. According to the invention, rapid and low-cost preparation of the compound eye microlens array can be achieved, and the high controllability of the shape, the diameter and the crown height of the bionic compound eye can be met.

Owner:HUAZHONG UNIV OF SCI & TECH

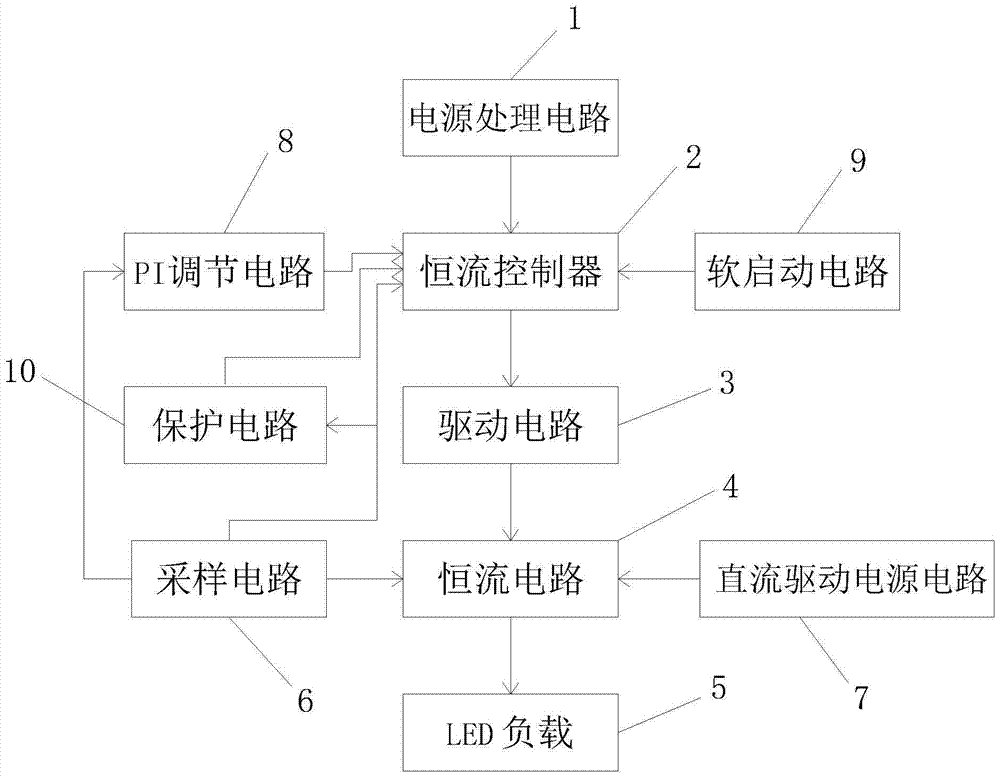

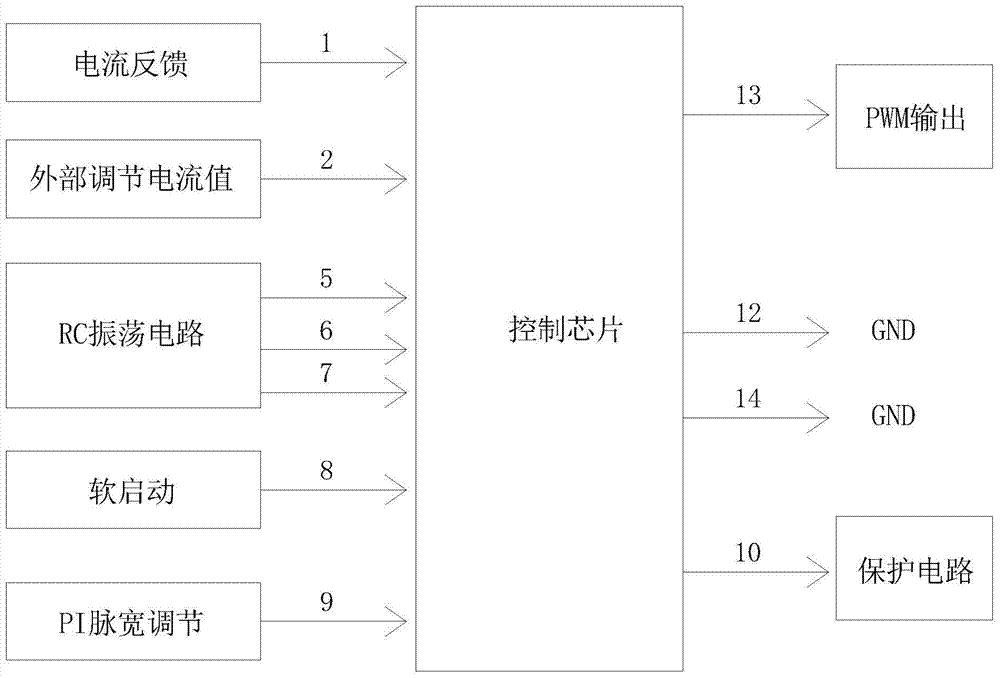

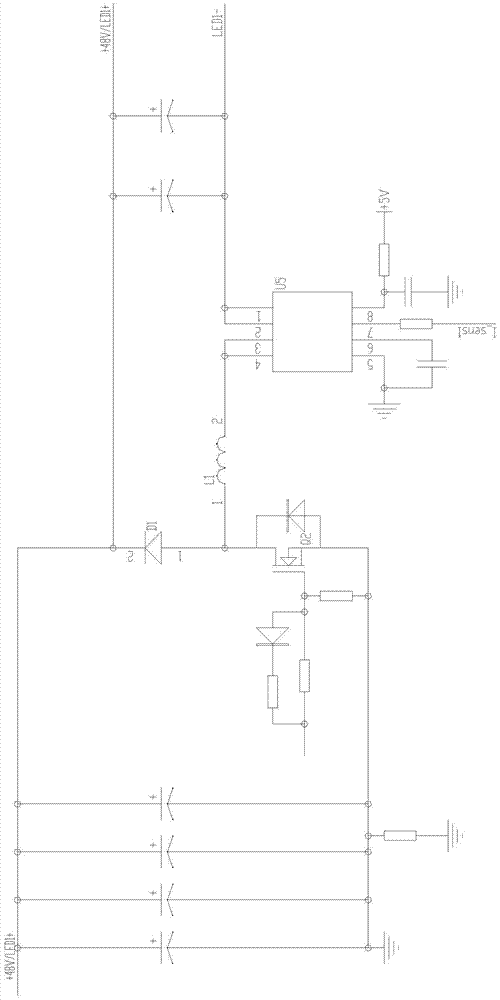

High current constant current ultraviolet light control circuit

ActiveCN105472809BReduce lossSimple designElectrical apparatusElectroluminescent light sourcesDriver circuitUltraviolet lights

The invention relates to a large-current constant-current ultraviolet light control circuit, which has a power processing circuit, a constant-current controller, a drive circuit, a constant-current circuit and an LED load sequentially connected; the input end of the constant-current circuit is also connected with a sampling circuit, The output terminals of the DC driving power supply circuit are connected; the output terminals of the sampling circuit are connected with the input terminals of the constant current controller; the output terminals of the sampling circuit are connected with the input terminals of the PI regulation circuit; the output terminals of the PI regulation circuit It is connected with the input terminal of the constant current controller; the constant current circuit includes a BUCK step-down topology circuit. The invention can stably output a large current of 25A, reduce the loss of the current, simplify the design of the driving circuit and save the cost.

Owner:JIANGSU GULIDE PRECISION PHOTOELECTRIC

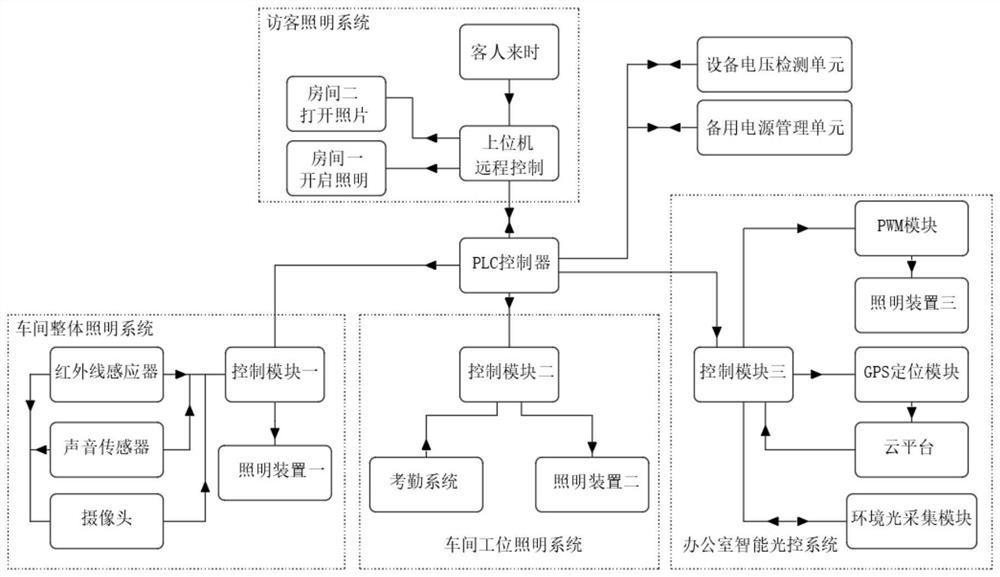

Intelligent controller for illumination

PendingCN114071844AImprove accuracyAvoid wasting electricityElectrical apparatusEnergy saving control techniquesInfraredEngineering

The invention, which relates to the technical field of the illumination control system, discloses an intelligent controller for illumination. The controller comprises an upper computer remote controller, a PLC controller, a workshop overall illumination system, a workshop station illumination system, an office intelligent light control system and a visitor illumination system. The workshop overall illumination system comprises an infrared sensor, a sound sensor, a camera, a first control module and a first illumination device, and the infrared sensor, the sound sensor, the camera and the first illumination device are all connected with the first control module. Under the effect of a plurality of distributed systems, illumination devices are automatically turned on and turned off, illumination devices at stations are turned on and turned off according to the attendance checking conditions of employees, the light intensity is automatically adjusted, a visitor illumination system is additionally arranged, the systems can be matched and used mutually, and the controller is high in practicality, and achieves the intelligent and multi-functional effects.

Owner:江苏赛孚士生物技术有限公司

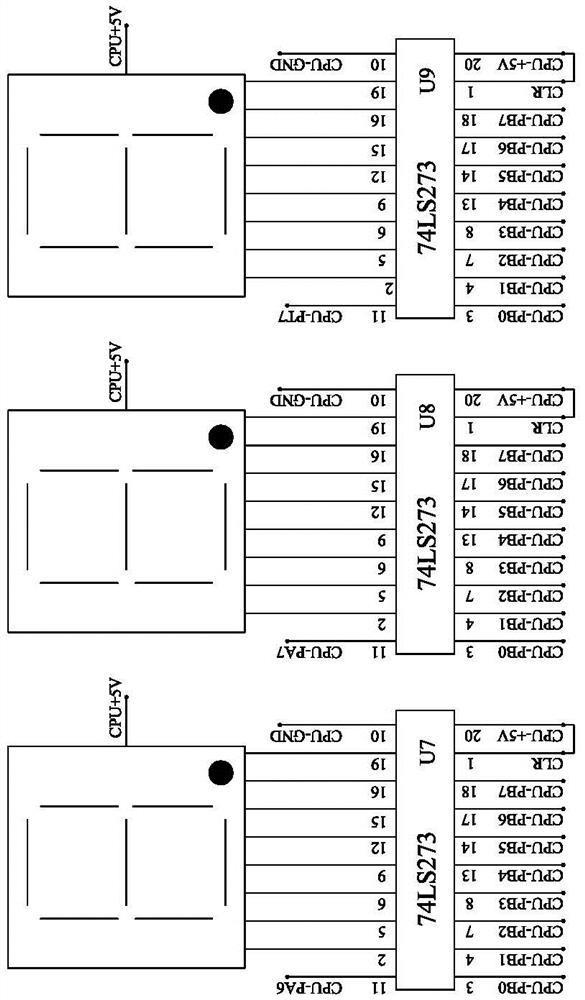

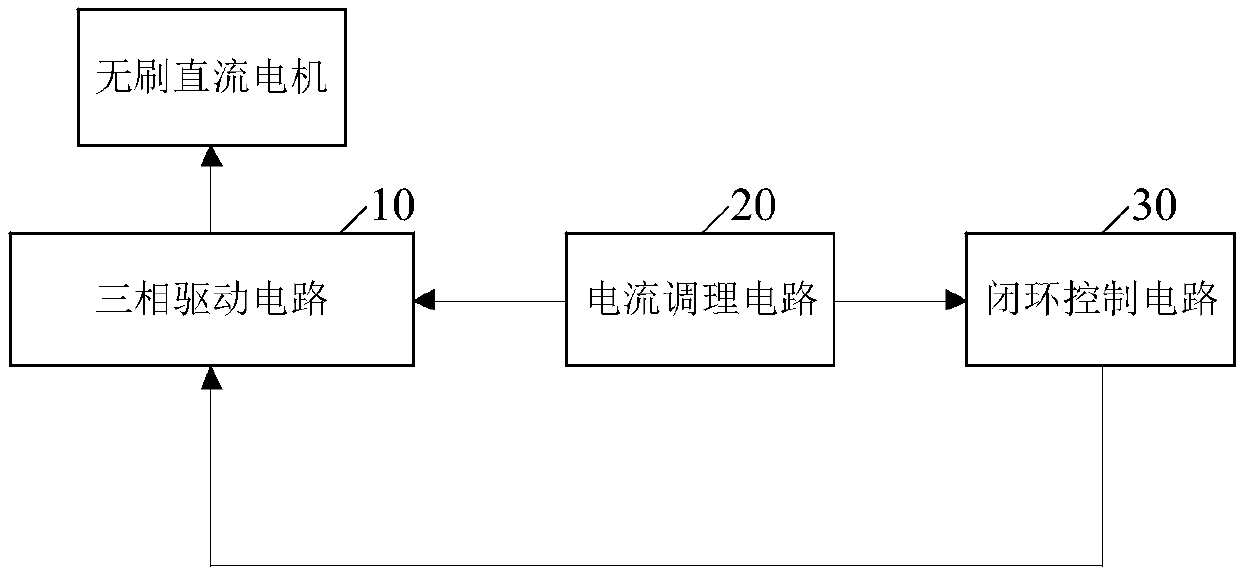

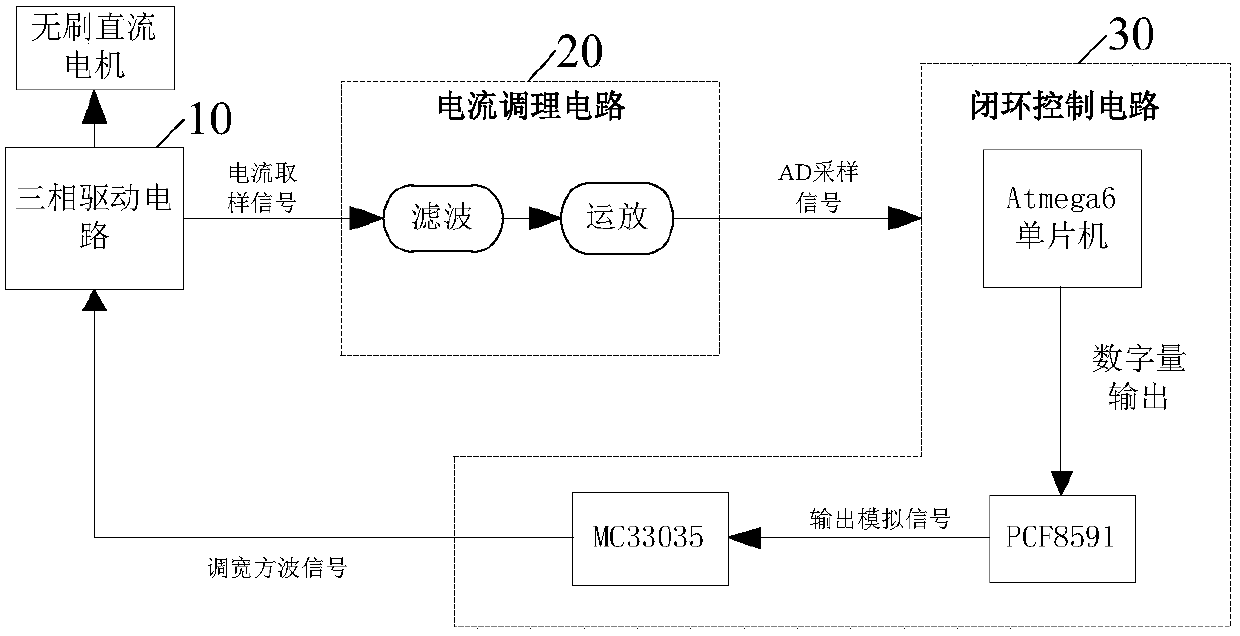

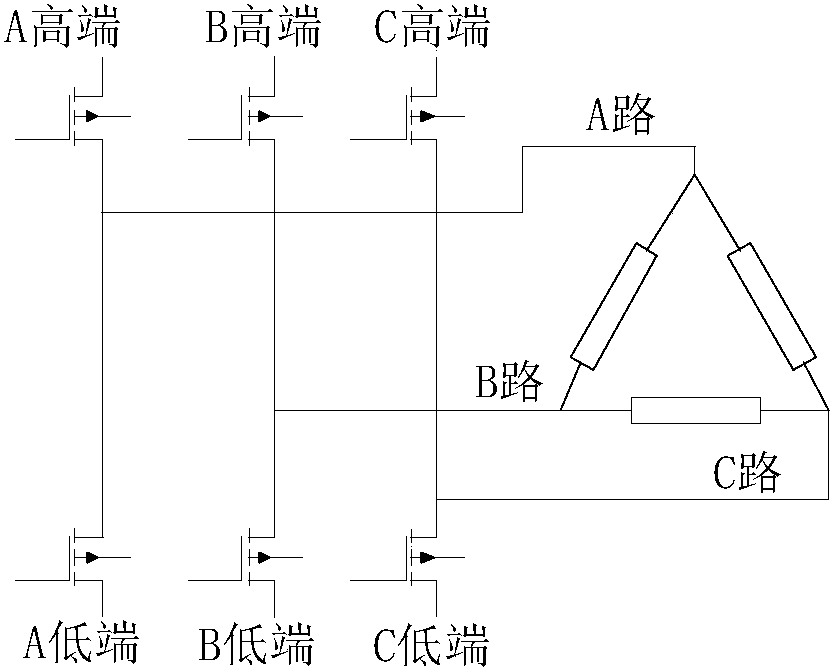

Current loop control system for brushless DC motor and control method

PendingCN107681931AControl duty cycleSimple structureElectric motor controlCurrent controllersCurrent loop controlControl system

The invention discloses a current loop control system for a brushless DC motor and a control method and belongs to the field of driven closed-loop control of DC motors. The current loop control systemcomprises a three-phase drive circuit, a current conditioning circuit and a closed-loop control circuit, wherein a drive output end of the three-phase drive circuit is connected with the brushless DCmotor, and a current output end is connected with an input end of the current conditioning circuit; and the input end of the closed-loop control circuit is connected with an output end of the currentconditioning circuit, and the output end is connected with the input end of the three-phase drive circuit. The invention further discloses a control method for the current loop control system for thebrushless DC motor. The system is simple in circuit structure and has extremely high expandability.

Owner:NO 43 INST OF CHINA ELECTRONICS TECH GRP CETC

Liquid crystal display, driving method thereof, and electronic device

ActiveCN106098012BIncrease opening ratioAchieve color cast compensationStatic indicating devicesTime scheduleLiquid-crystal display

The invention provides a driving method of a liquid crystal display. The driving method of the liquid crystal display comprises steps that a time schedule controller is used to output a source electrode enabling signal to a source electrode driver, and is used to output grid electrode enabling signal to a grid electrode driver; the source electrode driver is used to receive the source electrode enabling signal, and a duty ratio of a source electrode driving signal output to a source electrode line is reduced based on the source electrode enabling signal; the grid electrode driver is used to receive the grid electrode enabling signal, and a duty ratio of a grid electrode driving signal output to a grid electrode line is reduced based on the grid electrode enabling signal. The invention also provides the liquid crystal display and an electronic device. The liquid crystal display can be provided with a four-domain structure, and a quantity of electronic components is reduced based on improvement of color cast, and then an aperture ratio of a pixel is improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

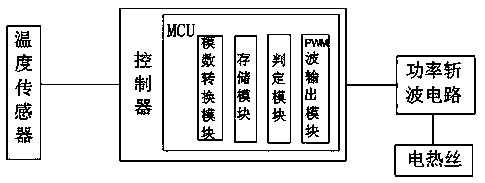

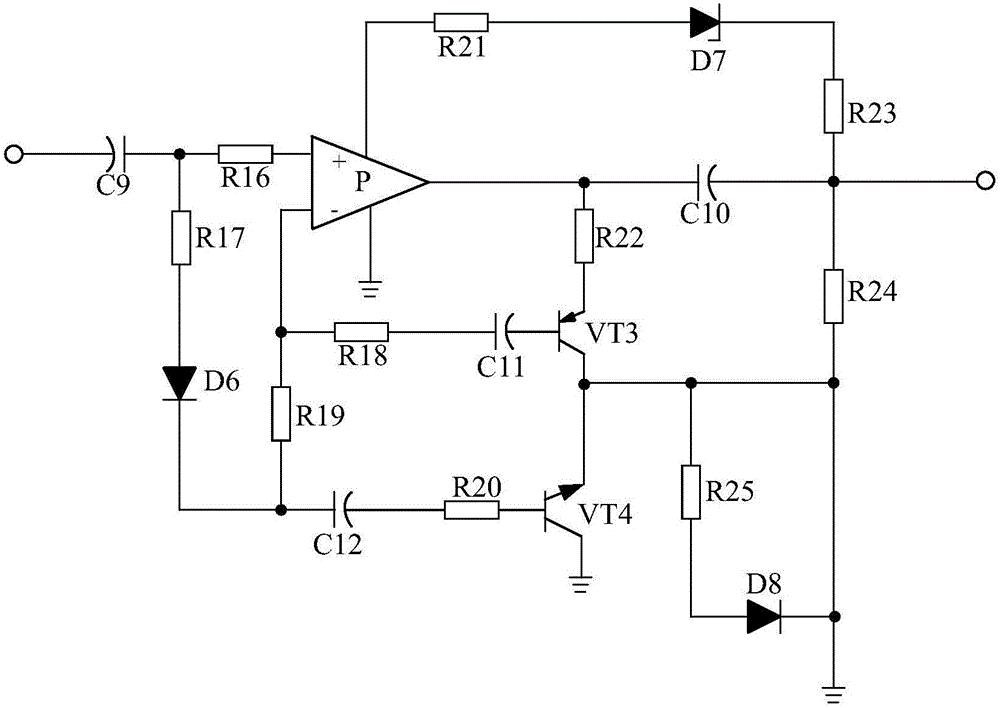

Intelligent bath heater for shower room

InactiveCN108930999AAdjust heating temperatureControl duty cycleLighting and heating apparatusElectric heating systemPower chopperVoltage

The invention relates to an intelligent bath heater for a shower room. The intelligent bath heater for the shower room comprises a shell; a warm air channel is arranged inside the shell; the air outlet end of the warm air channel is arranged on the lower surface of the shell and communicates with the outer side; an electric heating wire is arranged inside the warm air channel; an air blowing device is arranged on the inner side of the warm air channel and blows heat generated by the electric heating wire out of the air outlet end of the warm air channel; the intelligent bath heater further comprises a controller, a temperature sensor and a power chopper circuit; the controller comprises an MCU; an analog-digital conversion module, a storage module, a judgment module and a PWM wave output module are arranged inside the MCU; a reasonable temperature threshold value T is stored inside the storage module and corresponds to a preset duty ratio D; the output end of the temperature sensor isconnected with the input end of the analog-digital conversion module in the MCU; the output end of the PWM wave output module is connected with the first input end of the power chopper circuit; the second input end of the power chopper circuit is connected with the mains supply; and the output end of the power chopper circuit is connected with the voltage input end of the electric heating wire.

Owner:苏州妙文信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com