High current constant current ultraviolet light control circuit

A control circuit and high-current technology, applied in the field of high-current constant-current ultraviolet control circuits, can solve the problems of complex drive circuit design, high cost, and increased current loss, and achieve the expansion of the adjustable range of the duty cycle and cost savings , The effect of reducing the loss of current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

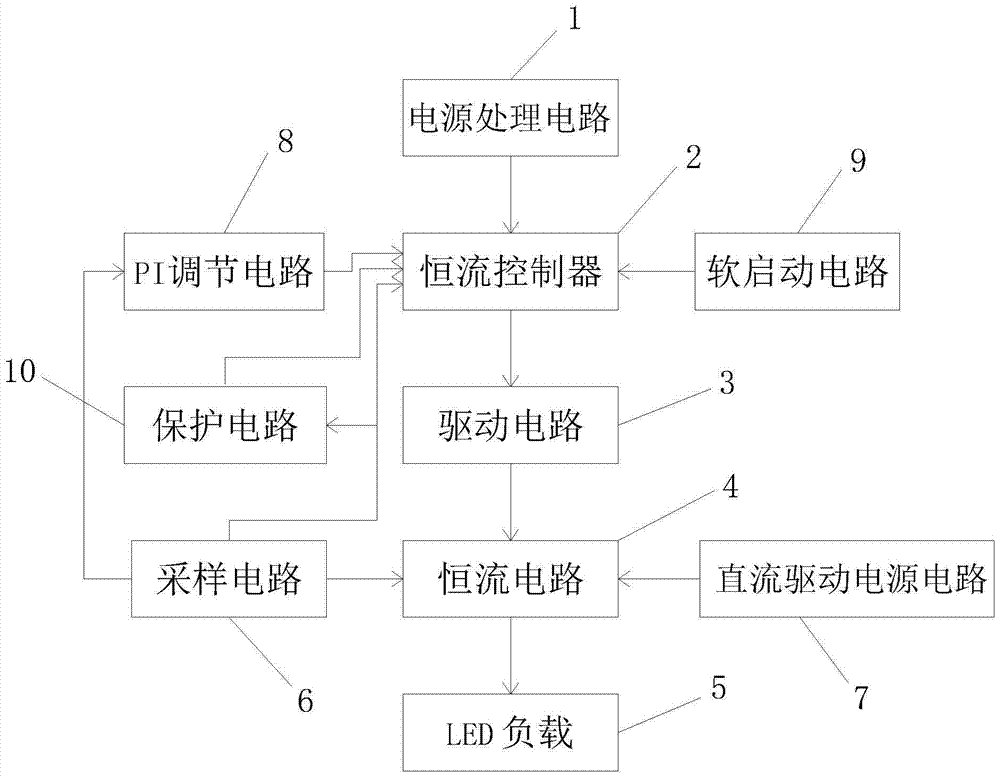

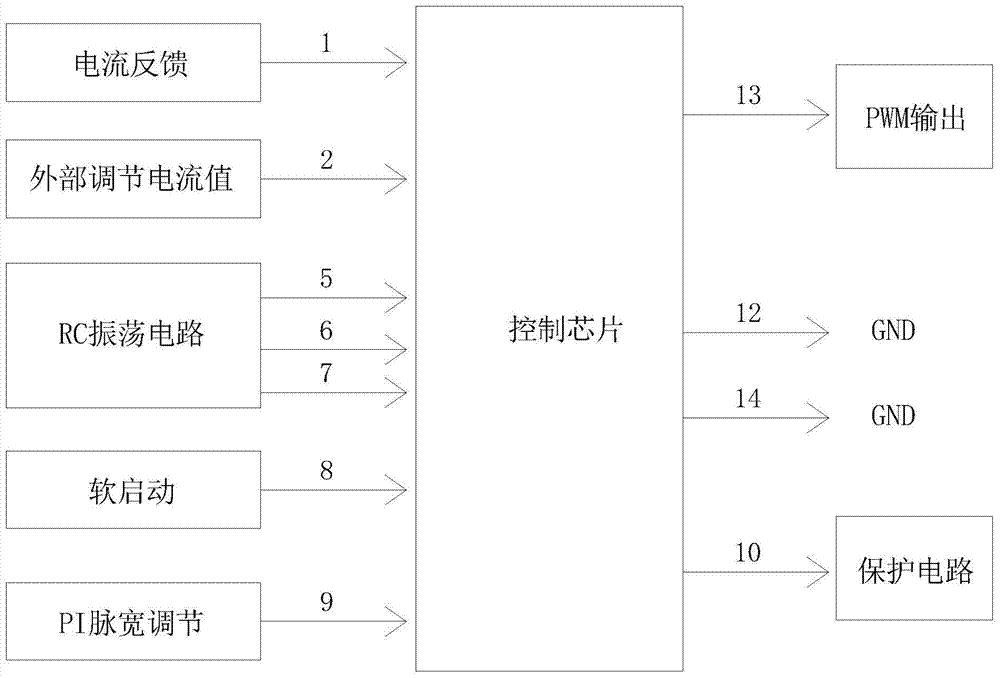

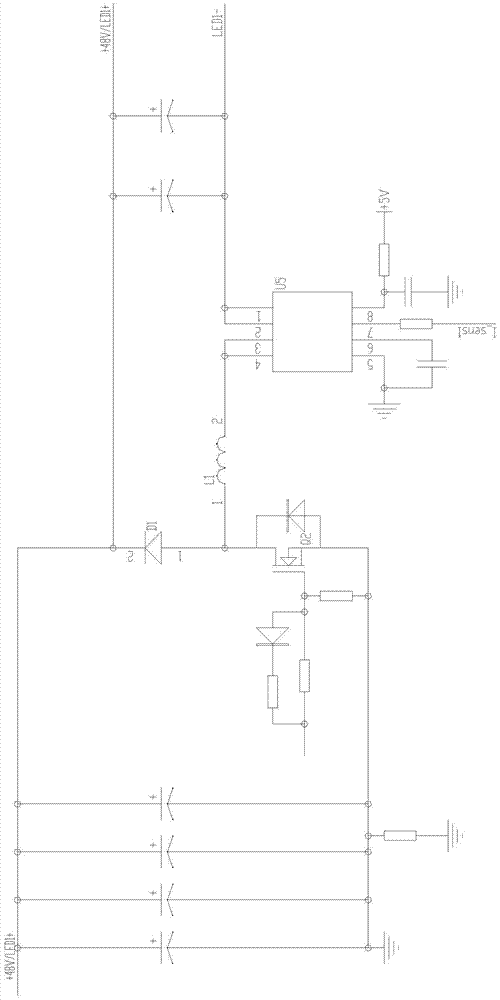

[0029] See figure 1 with figure 2 , the large current constant current ultraviolet light control circuit of this embodiment has a power processing circuit 1, a constant current controller 2, a drive circuit 3, a constant current circuit 4 and an LED load 5 connected in sequence; the input end of the constant current circuit 4 is also It is connected with the output end of the sampling circuit 6 and the DC drive power supply circuit 7; the output end of the sampling circuit 6 is connected with the input end of the constant current controller 2; the output end of the sampling circuit 6 is connected with the input end of the PI adjustment circuit 8; the PI adjustment The output end of the circuit 8 is connected to the input end of the constant current controller 2; the constant current circuit 4 includes a BUCK step-down topology circuit.

[0030] It also has a soft start circuit 9 and a protection circuit 10; the output end of the soft start circuit 9 is connected to the input...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com