Monocrystalline silicon surface composite microstructure based on full-wave band anti-reflection and a preparation method thereof

A technology of surface compounding and monocrystalline silicon, applied in the field of photovoltaics, can solve the problems such as the inability to realize the utilization of long-wavelength solar energy, and achieve the effects of improving utilization, improving conversion efficiency, and optimizing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

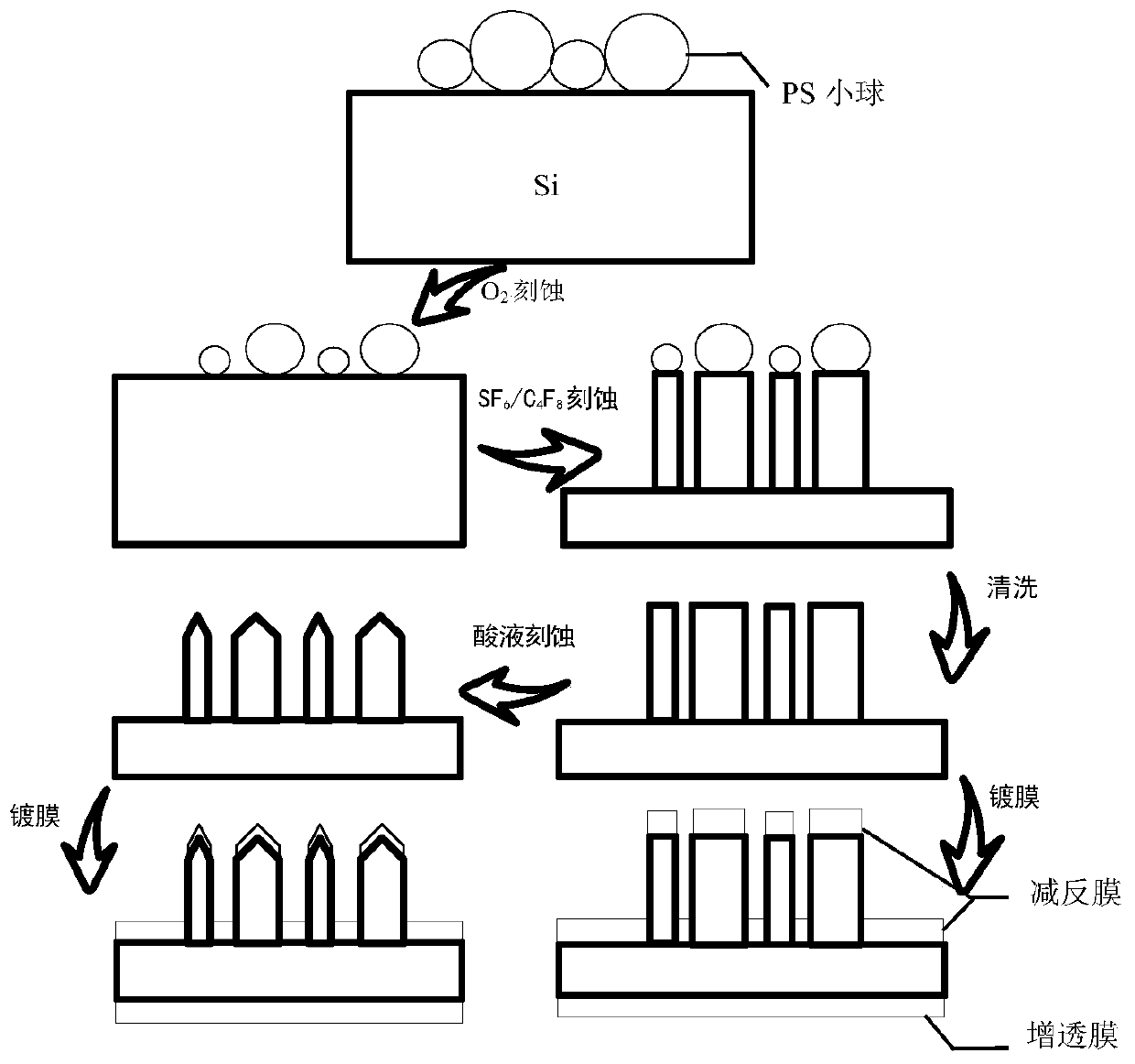

[0038] Such as figure 1 Shown is a flow chart of the present invention. A method for preparing a single crystal silicon surface composite microstructure based on full-band anti-reflection of the present invention includes part or all of the following steps (1) to (4), wherein each step is performed one or more times;

[0039](1) Silicon-based mask: Hydrophilic treatment of silicon wafers, preparation of a mixed solution of polystyrene beads, masking of silicon wafers after hydrophilic treatment, laying with a propulsion syringe, dripping sodium lauryl sulfate Solution, and use the pulling method to complete the mask, then air-dry the mask plate naturally, and then vacuum-dry it for 3 to 5 hours, and lay polystyrene beads on the surface of the silicon wafer;

[0040] Preferably, the steps of hydrophilic treatment of silicon wafers are: take single crystal silicon, wash, and cut the sample; place in a mixed solution of concentrated sulfuric acid and hydrogen peroxide, and heat ...

Embodiment 1

[0052] Example 1: Fabrication of nanopillar array structures with mixed diameters.

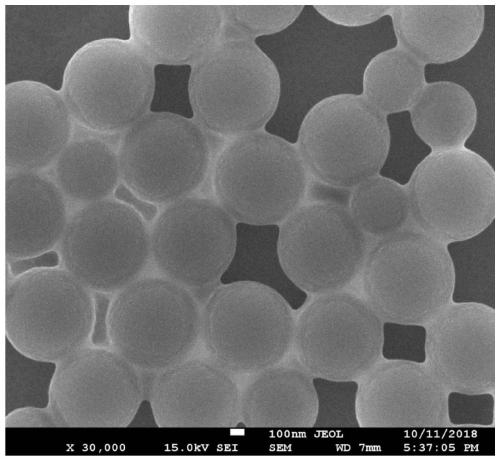

[0053] Select a 100mm×100mm circular double-sided polished P-type single crystal silicon, slice it with a diamond silicon wafer knife, and make a 25mm×25mm square silicon wafer substrate; mix the silicon wafer with concentrated sulfuric acid and hydrogen peroxide with a mass ratio of 7:3 Heat bath at 90°C for one hour in the solution to complete the hydrophilic treatment; prepare a mixed solution of polystyrene (Polystyrene, abbreviated as PS) beads: PS beads solution with a particle size of 400nm, PS beads solution with a particle size of 600nm, deionized Water and absolute ethanol are mixed according to the volume ratio of 0.5:0.5:3:7, and the mixture is ultrasonically oscillated at room temperature for 5 minutes; preparation of sodium dodecyl sulfate (SDS) solution: take 1 gram of sodium dodecyl sulfate 20mL deionized water, ultrasonic vibration for 20 minutes to dissolve it; take a 9mm×9mm...

Embodiment 2

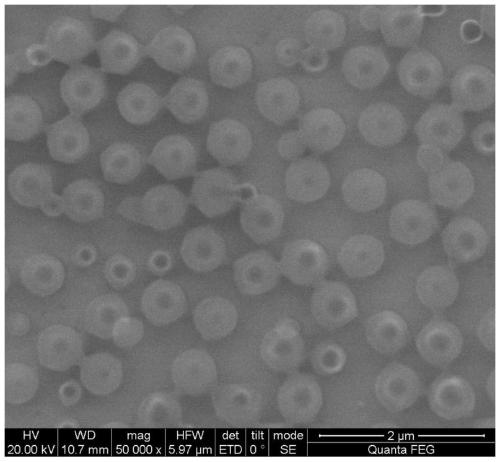

[0054] Example 2: Fabrication of Mixed Diameter Nano-Pencil Array Structure.

[0055] Select a 100mm×100mm circular double-sided polished P-type single crystal silicon, slice it with a diamond silicon wafer knife, and make a 25mm×25mm square silicon wafer substrate; mix the silicon wafer with concentrated sulfuric acid and hydrogen peroxide with a mass ratio of 7:3 Heat bath in the solution at a temperature of 90°C for one hour to complete the hydrophilic treatment; prepare a mixed solution of polystyrene (Polystyrene, abbreviated as PS) beads: a solution of nmPS beads with a particle size of 400, a solution of nmPS beads with a particle size of 600, and Ionized water and absolute ethanol are mixed according to the volume ratio of 0.5:0.5:3:7, and the solution is ultrasonically oscillated at room temperature for 5 minutes; preparation of sodium dodecyl sulfate (SDS) solution: take 1 gram of sodium dodecyl sulfate and put it in 20mL deionized water, ultrasonic vibration for 20 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com