A compound eye microlens array and its preparation method

A micro-lens array and compound eye technology, which is applied to lenses, instruments, optics, etc., can solve the problems of poor flexibility, loss of field of view, and high cost of template manufacturing, and achieve the goal of improving receiving efficiency, reducing spherical aberration, and reducing field of view loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

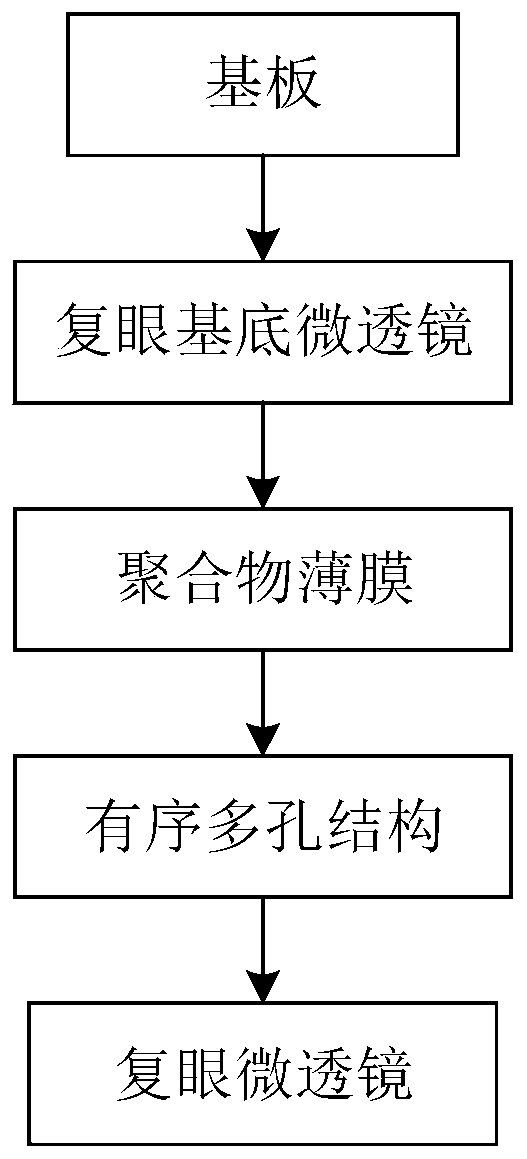

[0041] Such as figure 1 As shown, the present invention proposes a preparation method of a fly-eye microlens array, which is characterized in that the preparation method comprises the following steps:

[0042] (a) On a clean substrate, use photoresist hot-melt method, nanoimprint method, photolithography method, ion beam etching method, electrospray printing method or static breath pattern method to prepare compound eye base microlens array, the compound eye base microlens array The diameter of the lens array is preferably 200 μm to 400 μm, and the crown height is preferably 40 μm to 150 μm;

[0043] More specifically, when preparing a single fly-eye microlens, it is only necessary to prepare a single fly-eye base microlens on a clean substrate, and when preparing a fly-eye microlens array, it is necessary to prepare a fly-eye base microlens array on a clean substrate;

[0044] (b) Dissolve the polymer in a volatile solvent, configure a polymer solution with a concentration o...

Embodiment 1

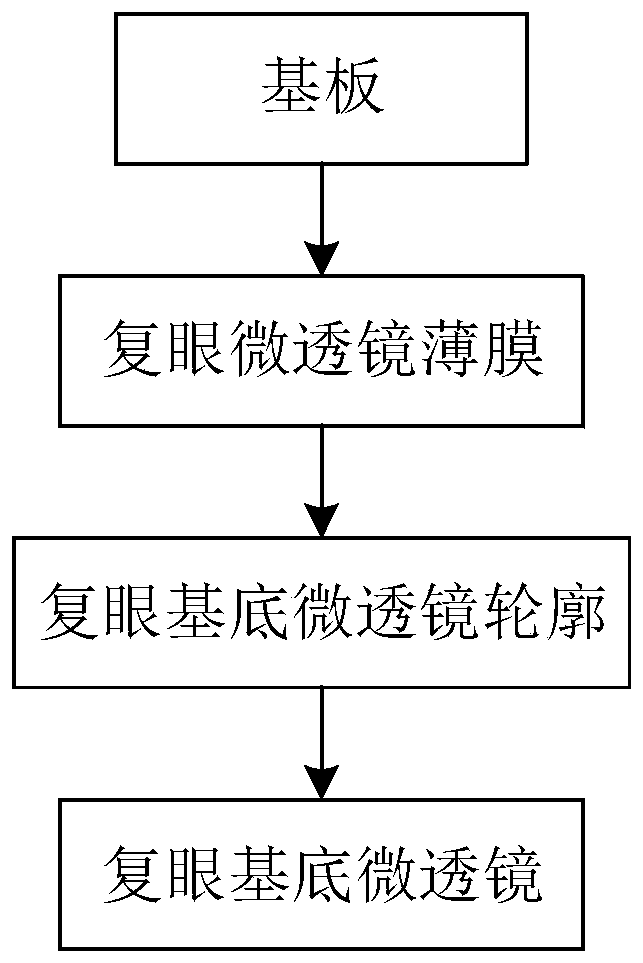

[0070] Such as Figure 3-7 As shown, the steps of preparing a curved surface fly-eye microlens array include:

[0071] (a) Fabrication of compound eye base microlens arrays by using the static breathing pattern method:

[0072] First, take a certain amount of polystyrene (PS) and place it in a volumetric flask, add a certain amount of toluene, seal it and dissolve it through ultrasonic vibration, and configure it into a PS toluene solution with a mass concentration of 25 mg / mL. 200 μL of PS toluene solution was evenly spin-coated on a 2cm×2cm substrate;

[0073] Then add 2mL of distilled water to a 25mL straight glass bottle equipped with a stopper, put a plastic support into the glass bottle, seal it with a stopper until the water vapor in the bottle reaches a humidity of 70%, place the substrate on the support, and make the substrate 1cm higher than the water level, then cover the plug and seal it, and let it stand at 25°C for 30s. After the toluene is completely volatiliz...

Embodiment 2

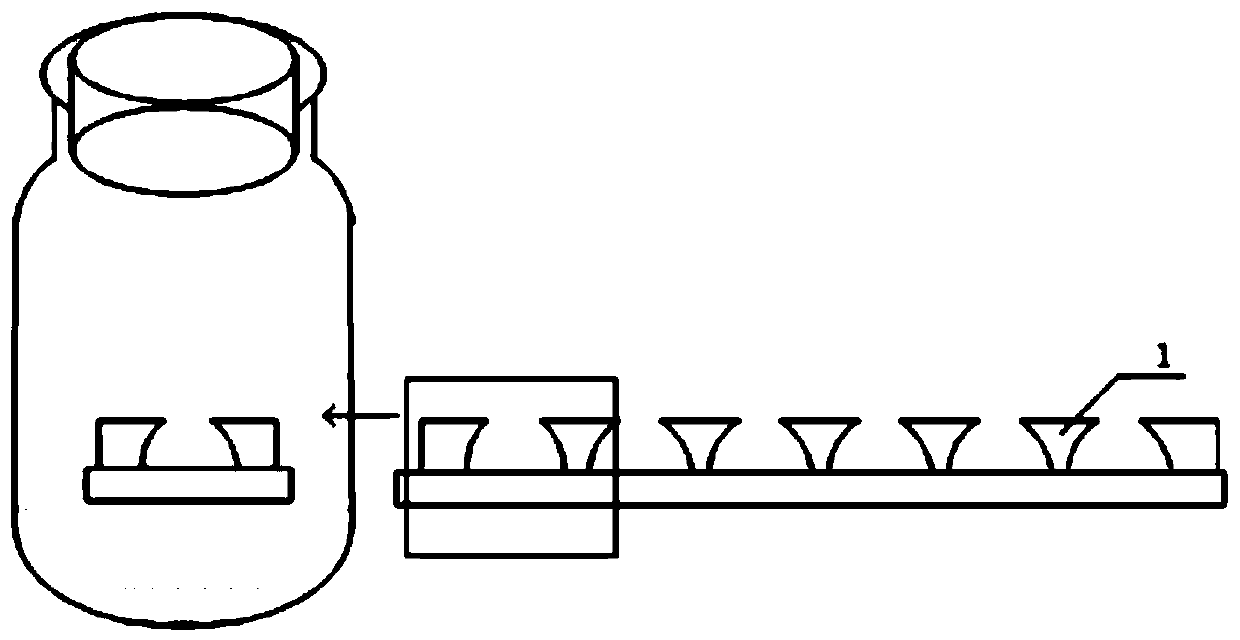

[0080] Utilize the method for step (a)~(c) in embodiment 1 to make the compound eye base microlens array with honeycomb ordered porous structure, then use Figure 8 A fly-eye microlens with a larger aspect ratio is prepared by using the wettability difference method as shown:

[0081] On the surface of the compound eye substrate microlens array with a honeycomb ordered porous structure, spin-coat a suspension of silica nanoparticles with a concentration of 4.2g / L, and control the thickness of the spin-coated silicon nanoparticles 6 to about 250nm. The particle 6 has a diameter of about 14nm, forming a surface with discontinuous wettability; then the substrate is put into the microlens solution 7, and then the substrate is pulled out, and the solution self-assembles to form a compound eye microlens 8 with a crown height of about 1.5 μm, and finally obtains the compound eye microlens array.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com