Four-group parallel inverter welding power supply control method and circuit

A technology of inverter welding power supply and control method, which is applied in the direction of welding equipment, manufacturing tools, arc welding equipment, etc., and can solve the problems of four groups of sub-circuit output current balance, frequency, pulse width, phase error, and enlarged circuit Problems such as output imbalance, to achieve stable output current, ensure output current, and improve reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

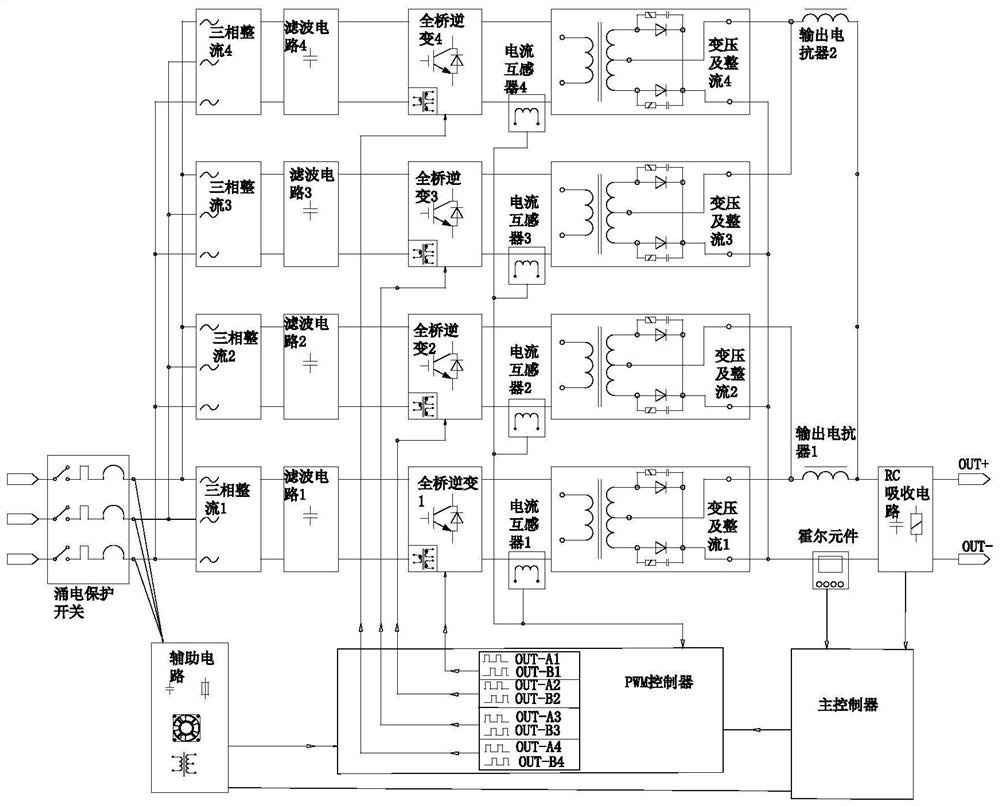

[0024] A four-group parallel inverter welding power supply circuit of the present application, such as figure 1 As shown, it includes a main controller, a PWM controller, an auxiliary circuit, and four sets of inverter sub-power supplies connected in parallel. The main controller is used to detect the output current of the whole power supply; each inverter sub-power supply includes a three-phase rectifier circuit connected in sequence , filter circuit, IGBT full-bridge inverter circuit, transformer and rectifier circuit, current detection circuit, the current detection circuit includes a current transformer, which is used to detect the inversion of each transformer and rectifier circuit input end, and IGBT full-bridge inverter circuit output To change the output current of the sub-power supply, the main controller is used to control the PWM controller to output four PWM signals that are independent of each other and whose rising edges are synchronous. A set of PWM signals is us...

specific Embodiment 2

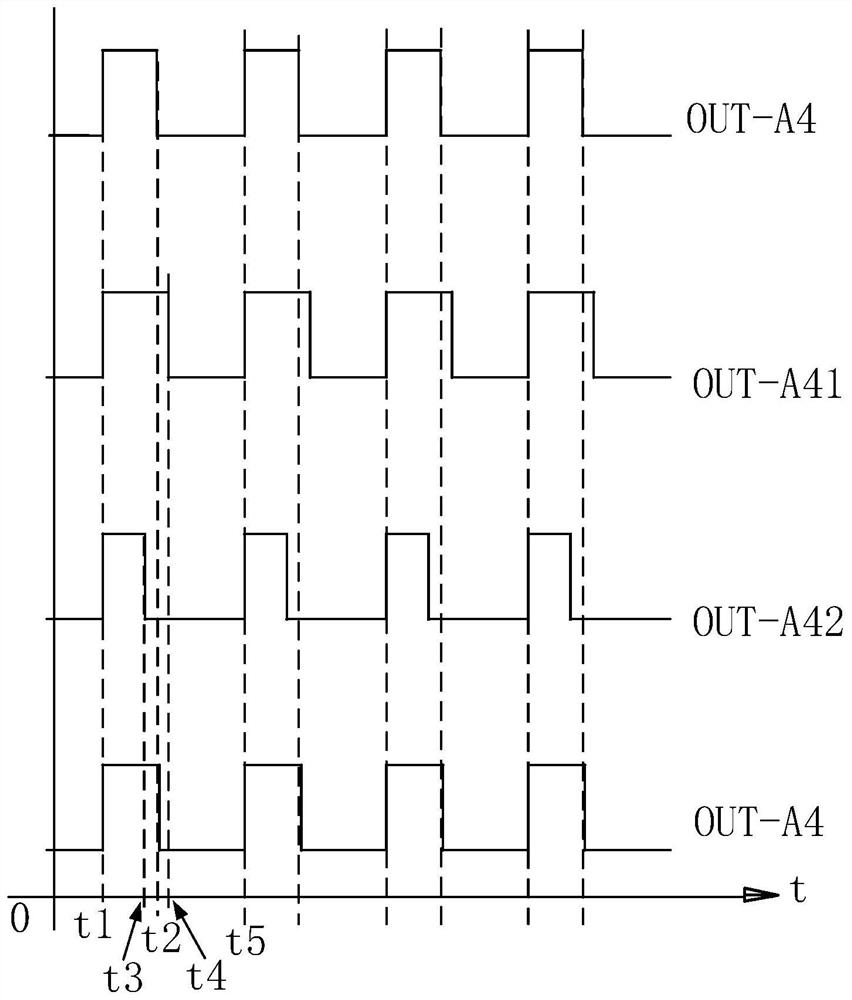

[0045] According to a method for controlling four groups of parallel inverter welding power sources in the present application, the PWM controller outputs four groups of independent PWM control signals, each group of PWM control signals includes two PWM control signals with a phase difference of 180 degrees, and each PWM control signal It is used to drive the conduction or cut-off of the two IGBT tubes at the corresponding positions of the IGBT full-bridge inverter circuit.

[0046] The main controller controls the rising edge synchronization of four independent PWM control signals, detects the output current of each inverter sub-power supply, compares the output current of each inverter sub-power supply with the current set value, and controls the falling edge of each PWM signal. At the time of shutdown, reduce the PWM signal duty cycle of the inverter sub-power supply with large output current, increase the PWM signal duty cycle of the inverter sub-power supply with small out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com