A parallel dc-dc circuit control method, system, electronic equipment and storage medium

A DC-DC, circuit control technology, applied in the control/regulation system, electrical components, regulating electrical variables, etc., can solve the problem of current unbalanced, etc., to achieve the effect of balanced output current, stable output voltage, and guaranteed dynamic response performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

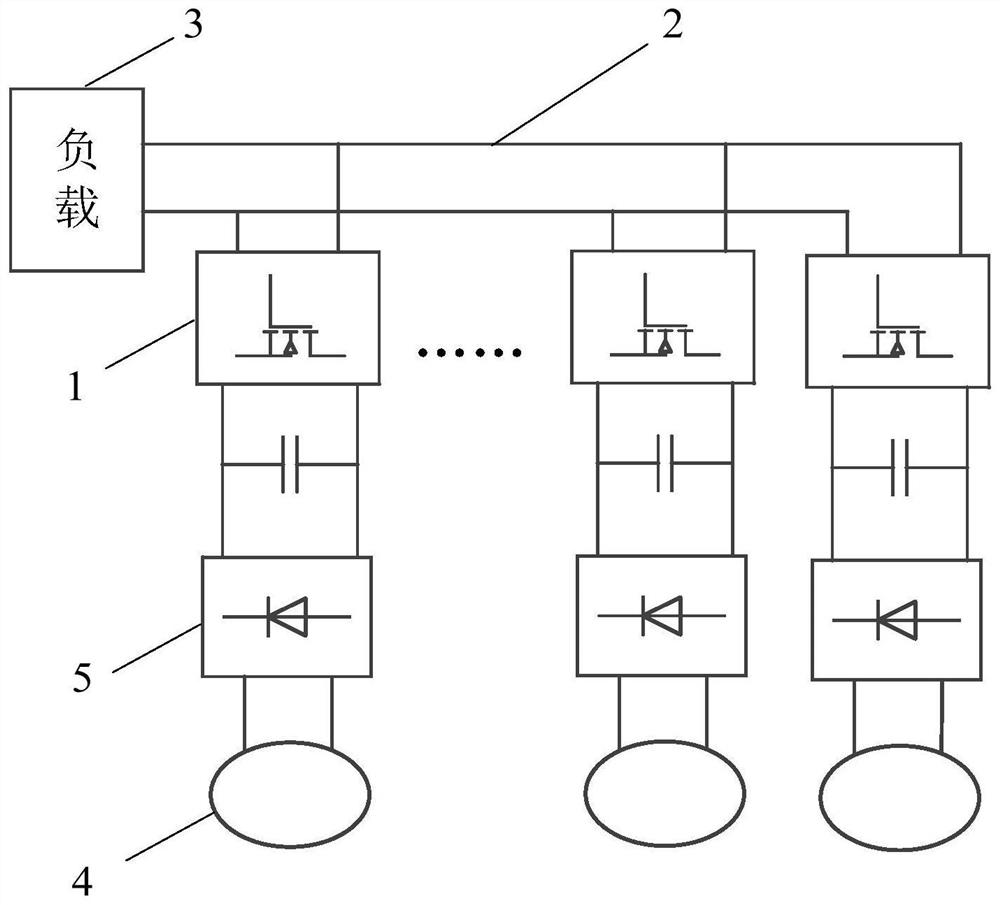

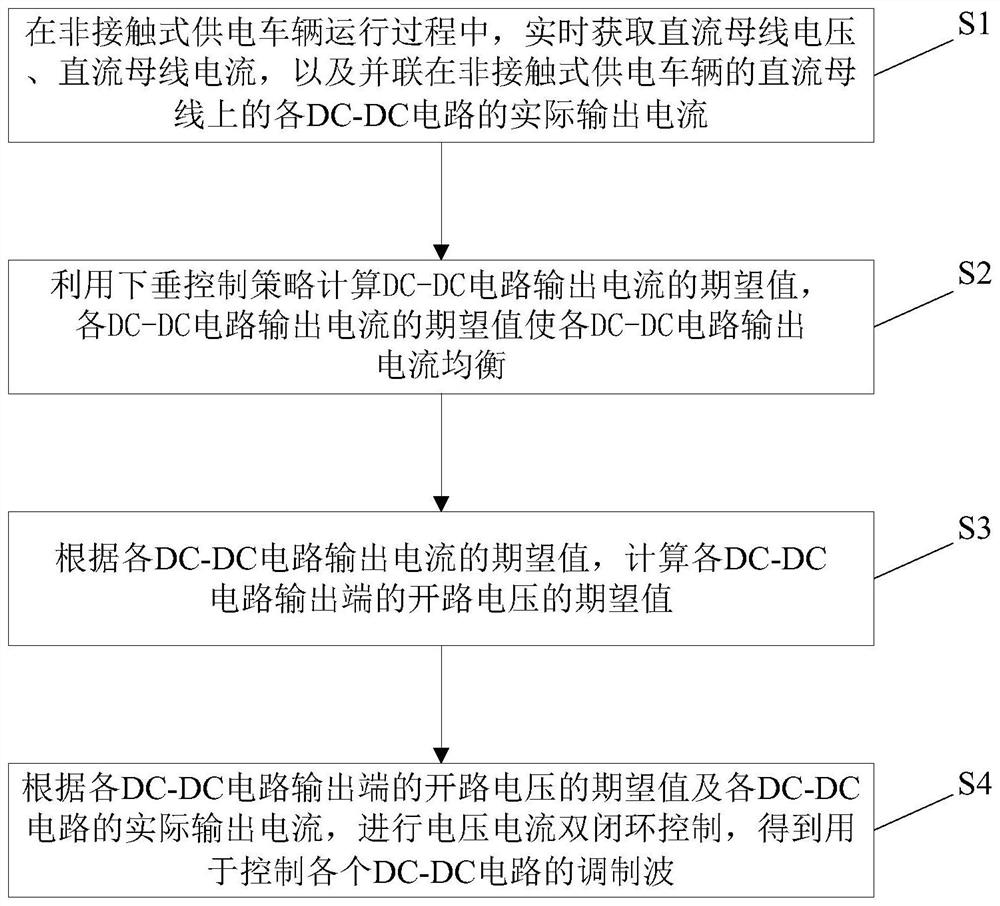

[0051] This embodiment provides a method for controlling a parallel DC-DC circuit, image 3 Shows a flowchart of a parallel DC-DC circuit control method, the method is applied to non-contact power supply vehicles, such as image 3 As shown, the method includes the following steps:

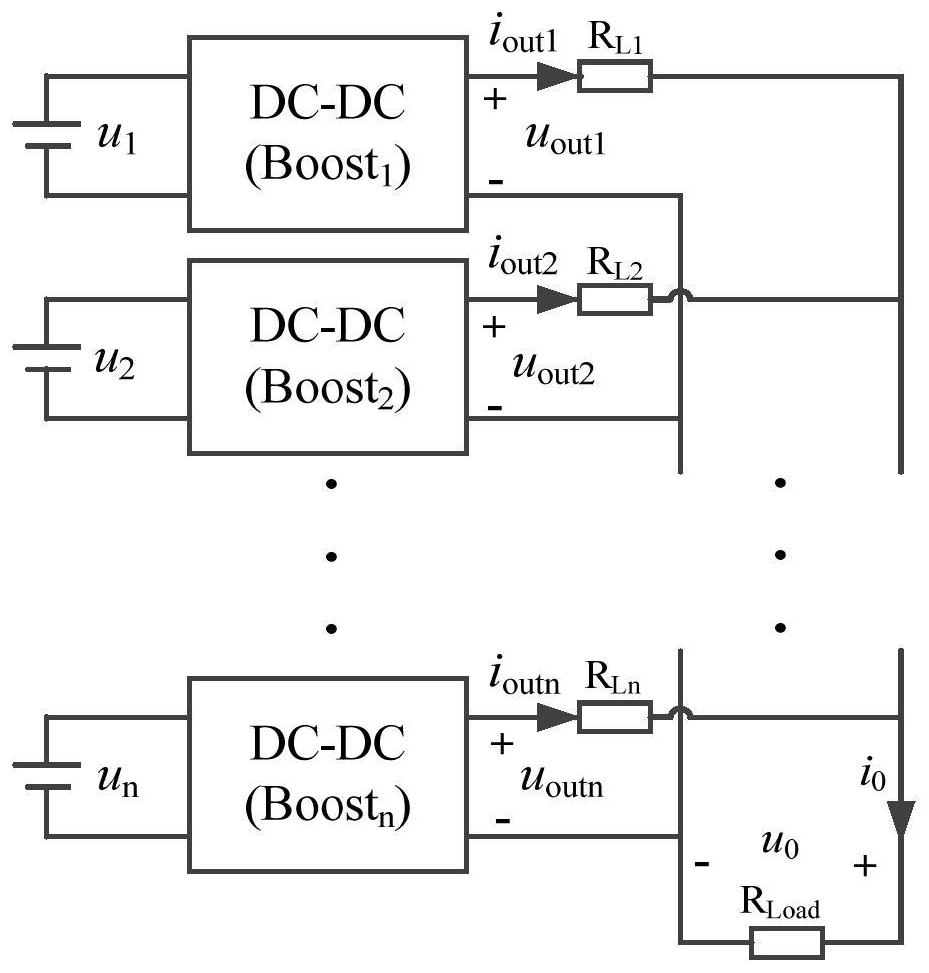

[0052] Step S1, during the operation of the non-contact power supply vehicle, obtain the DC bus voltage, the DC bus current, and the actual output current i of each DC-DC circuit connected in parallel to the DC bus of the non-contact power supply vehicle in real time out1 …i outn .

[0053] Step S2, using the droop control strategy to obtain the calculation formula of the expected value of the output current of the DC-DC circuit, the expected value of the output current of each DC-DC circuit balances the output current of each DC-DC circuit.

[0054] Step S3. Calculate the expected value of the open-circuit voltage at the output end of each DC-DC circuit according to the calculation formula of t...

Embodiment 2

[0097] Corresponding to Embodiment 1, this embodiment provides a parallel DC-DC circuit control system, which is applied to non-contact power supply vehicles, such as Figure 12 As shown, the system includes:

[0098] An acquisition module, configured to obtain in real time the DC bus voltage, the DC bus current, and the actual output current of each DC-DC circuit connected in parallel to the DC bus of the contactless power supply vehicle during the operation of the non-contact power supply vehicle;

[0099] The first calculation module is used to obtain the calculation formula of the expected value of the output current of each DC-DC circuit by using the droop control strategy, and the expected value of the output current of each DC-DC circuit balances the output current of each DC-DC circuit;

[0100] The second calculation module is used to calculate the expected value of the open circuit voltage at the output end of each DC-DC circuit according to the calculation formula o...

Embodiment 3

[0104] This embodiment provides an electronic device, which includes a memory and a processor, where a computer program is stored on the memory, and when the computer program is executed by the processor, the method for controlling a parallel DC-DC circuit according to the first embodiment is implemented.

[0105] The processor in this embodiment may be an Application Specific Integrated Circuit (ASIC for short), a Digital Signal Processor (DSP for short), a Digital Signal Processing Device (DSPD for short), a programmable A logic device (ProgrammableLogic Device, referred to as PLD), a field programmable gate array (Field Programmable Gate Array, referred to as FPGA), a controller, a microcontroller, a microprocessor or other electronic components are used to implement the parallel connection in the above-mentioned embodiment DC-DC circuit control method. For the method implemented when the computer program running on the processor is executed, reference may be made to the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com