Composite oil and gas hose with optical fiber communication and monitoring functions

An optical fiber communication and composite technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of increasing engineering cost, low sensitivity and accuracy of monitoring system, saving engineering cost, improving sensitivity, accuracy, and engineering cost. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

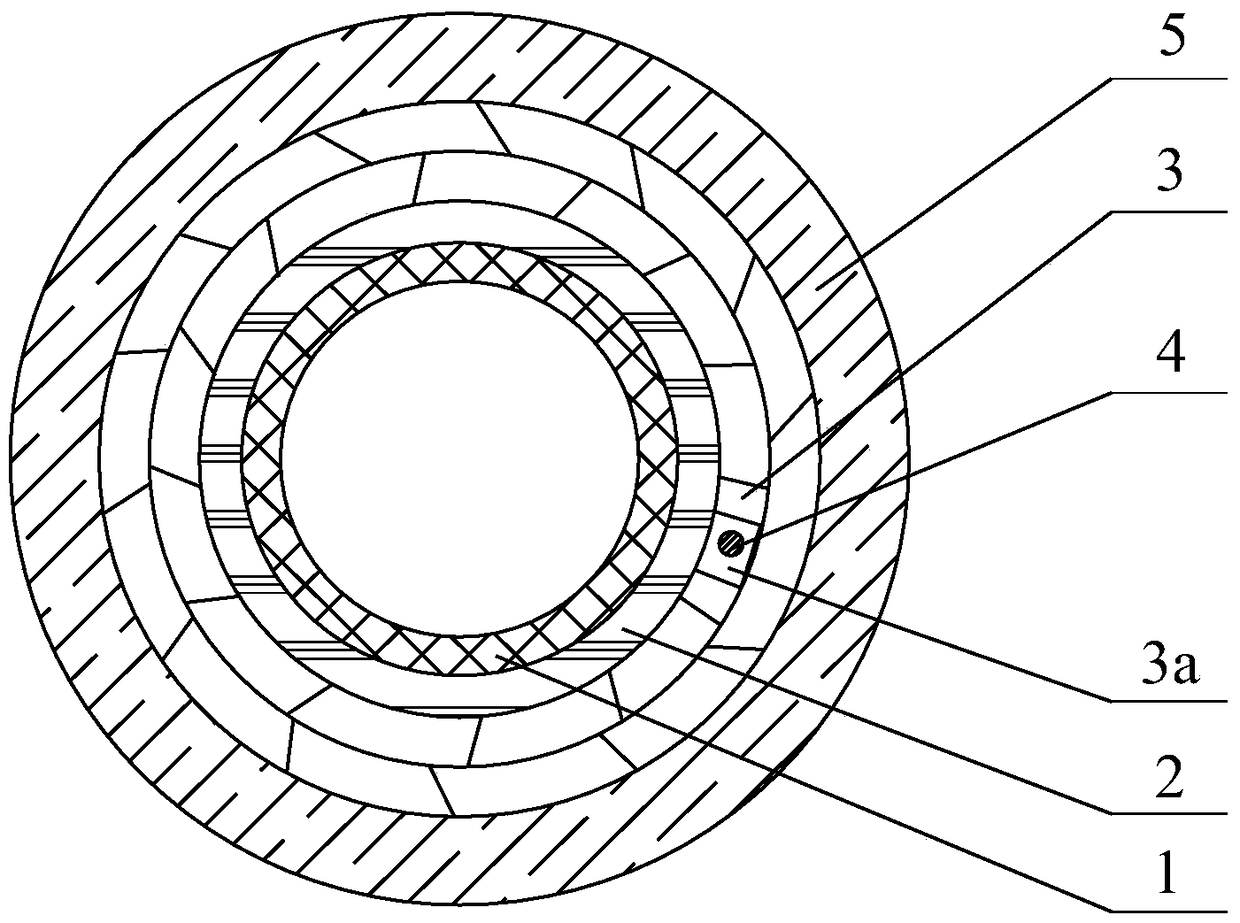

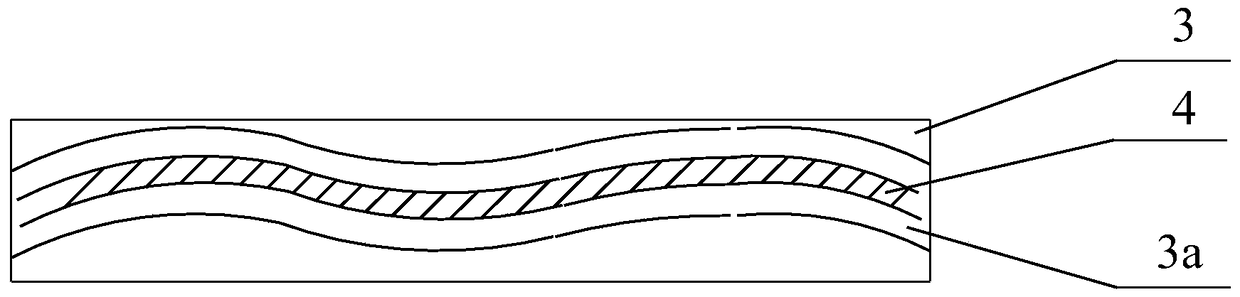

Embodiment 1

[0032] This embodiment provides a composite oil and gas hose with optical fiber communication and monitoring functions. The composite oil and gas hose includes a metal hose 1, an inner sheath 2, several flat steel strips 3, optical cables 4, Outer sheath5. The metal hose 1 is made of several buckle-shaped steel strips, which are continuously clamped one by one. The buckle-shaped steel strips are made of stainless steel with a thickness of 3mm; the inner sheath 2 is made of high-density polyethylene, which is extruded by an extruder. The thickness is 3mm; there are two layers of flat steel strips 3 closely surrounding the inner sheath 2, and one layer of flat steel strips 3 that is close to the inner sheath 2 is arranged in a clockwise direction, and the other All the flat steel strips 3 of one layer are arranged in the counterclockwise direction. In a layer of flat steel belt 3 close to the inner sheath 2, there is a flat steel belt 3 with a wire groove 3a inside, and the wir...

Embodiment 2

[0034] This embodiment provides a composite oil and gas hose with optical fiber communication and monitoring functions. The composite oil and gas hose includes a metal hose 1, an inner sheath 2, several flat steel strips 3, optical cables 4, Outer sheath5. The metal hose 1 is made of several buckle-shaped steel strips, which are continuously clamped one by one. The buckle-shaped steel strips are made of stainless steel with a thickness of 2mm; the inner sheath 2 is made of high-density polyethylene, which is extruded by an extruder. The thickness is 3mm; there are two layers of flat steel strips 3 closely surrounding the inner sheath 2, and one layer of flat steel strips 3 that is close to the inner sheath 2 is arranged in a clockwise direction, and the other All the flat steel strips 3 of one layer are arranged in the counterclockwise direction. In a layer of flat steel belt 3 close to the inner sheath 2, there is a flat steel belt 3 with a wire groove 3a inside, and the wir...

Embodiment 3

[0036] This embodiment provides a composite oil and gas hose with optical fiber communication and monitoring functions. The composite oil and gas hose includes a metal hose 1, an inner sheath 2, several flat steel strips 3, optical cables 4, Outer sheath5. The metal hose 1 is made of several buckle-shaped steel strips, which are continuously clamped one by one. The buckle-shaped steel strips are made of stainless steel with a thickness of 5mm; the inner sheath 2 is made of high-density polyethylene, which is extruded by an extruder. The thickness is 3mm; several flat steel strips 3 are closely surrounded by two layers outside the inner sheath 2, and one layer of flat steel strips 3 close to the inner sheath 2 is arranged in a counterclockwise direction. All the flat steel strips 3 of one layer are arranged clockwise. In a layer of flat steel belt 3 close to the inner sheath 2, there is a flat steel belt 3 with a wire groove 3a inside, and the wire groove 3a runs through the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com