Lifting spray head of automatic glue spraying machine

A technology of automatic glue spraying machine and spray head, which is applied in the field of glue spraying machine, can solve the problem that it is not suitable for gluing on non-planar parts, and achieve the effect of simple structure and high glue spraying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

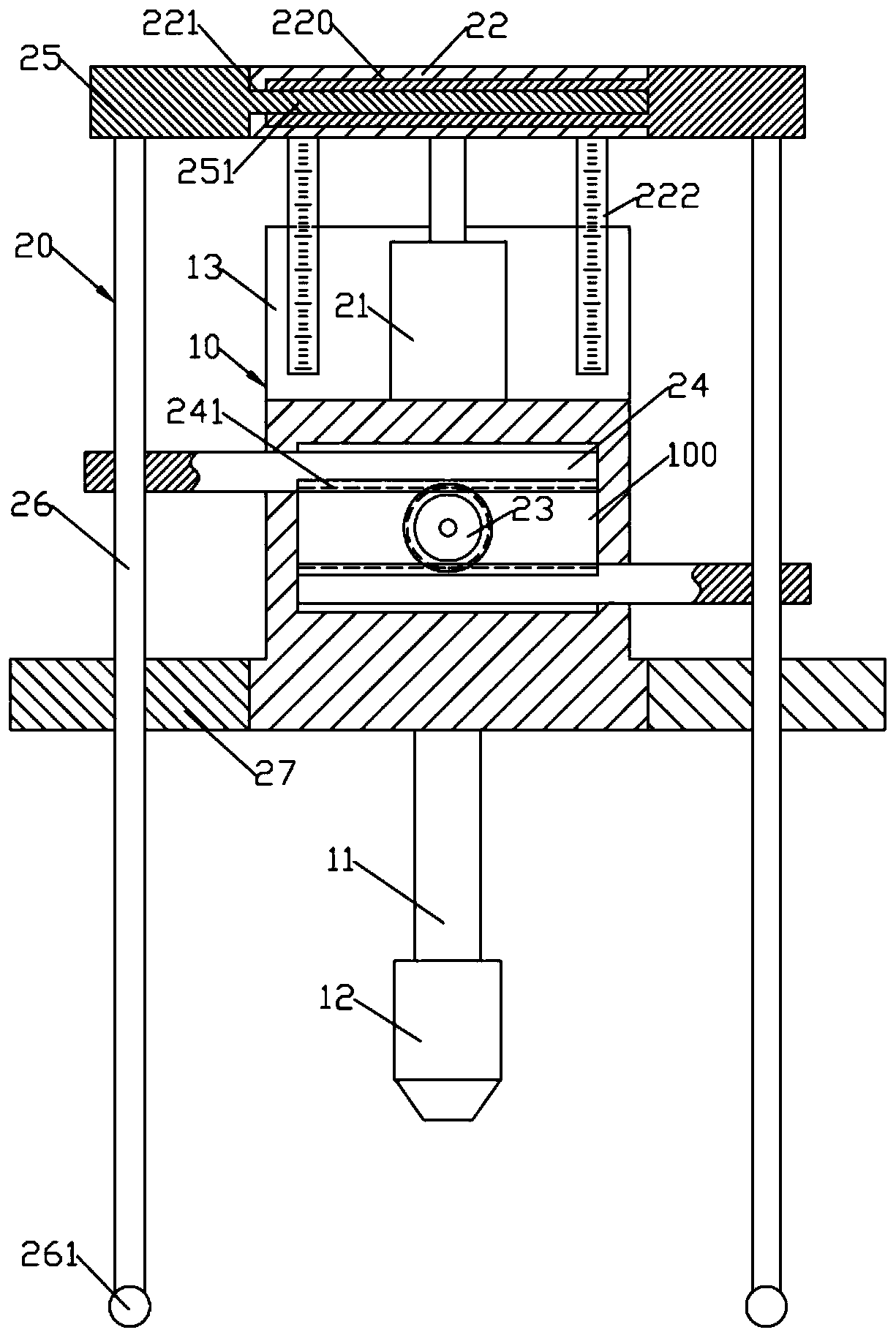

[0014] Such as figure 1 As shown, a lifting nozzle of an automatic glue spraying machine includes a nozzle support 10 and a nozzle limiter 20; the movable lift of the nozzle support 10 is set on the automatic glue sprayer and moves horizontally with the automatic glue sprayer; the nozzle limiter 20 includes a lifting support plate 22 arranged on the nozzle support 10; the left and right ends of the lifting support plate 22 move horizontally respectively to set a limit upper support plate 25; a pair of limit upper support plates 25 are synchronously separated or approached; A cylindrical limit rod 26 is formed on the lower end surface of the upper support plate 25; a nozzle support rod 11 is installed on the lower end surface of the nozzle support 10; a nozzle 12 is detachably installed on the lower end of the nozzle support rod 11; the limit rod The lower end of 26 is positioned at the lower side of nozzle 12 and a pair of limit rods 26 and nozzle 12 are on the vertical plane ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap