Bench drilling equipment for multi-station machining of non-mounting and dismounting drilling bit

A multi-station, machining technology, used in metal processing equipment, drilling/drilling equipment, components of boring machines/drilling machines, etc., can solve the problem of fixture stuck, increased limitations, and the position of the three drill bits cannot be adjusted and other problems to achieve the effect of reducing work time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

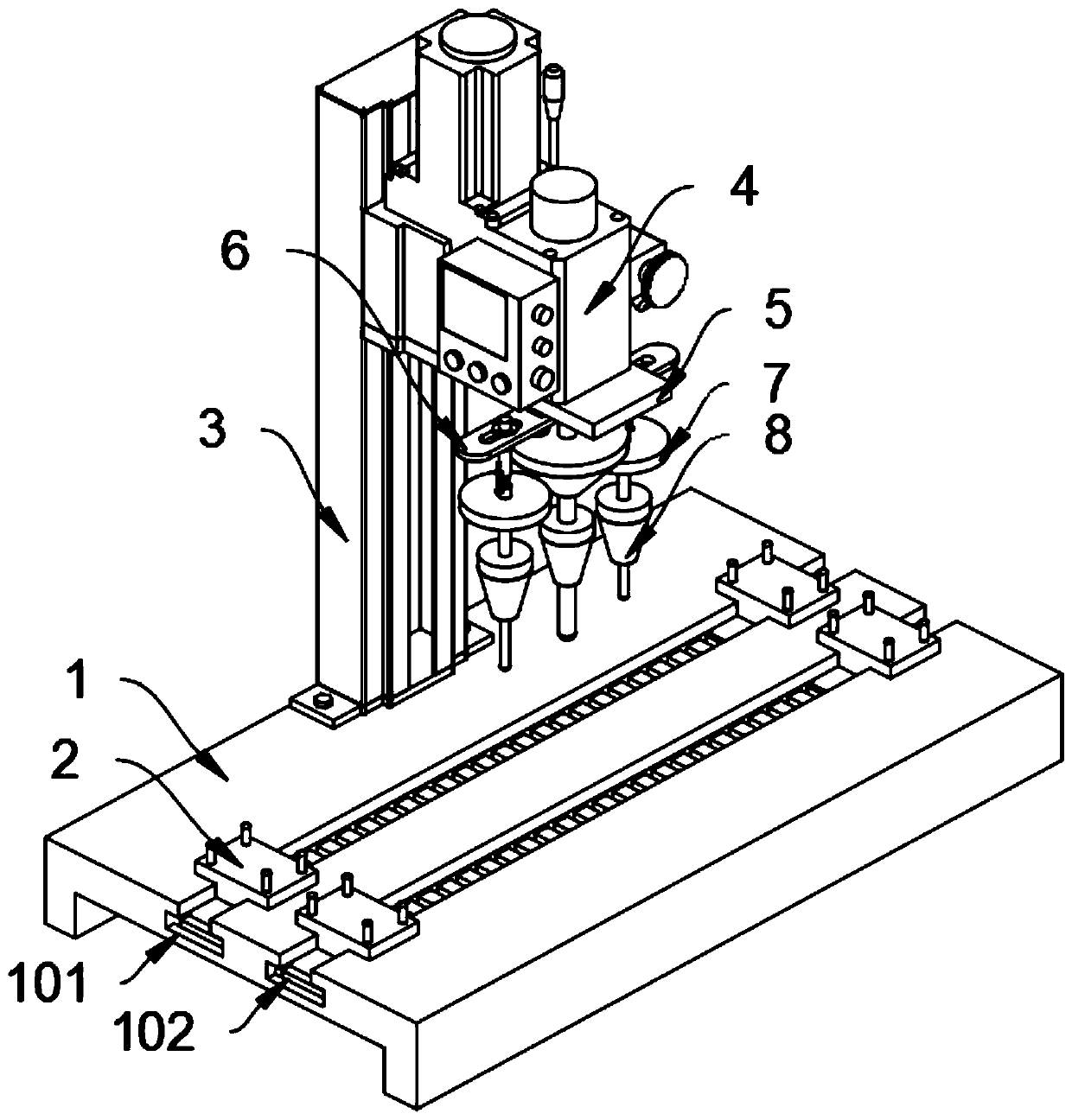

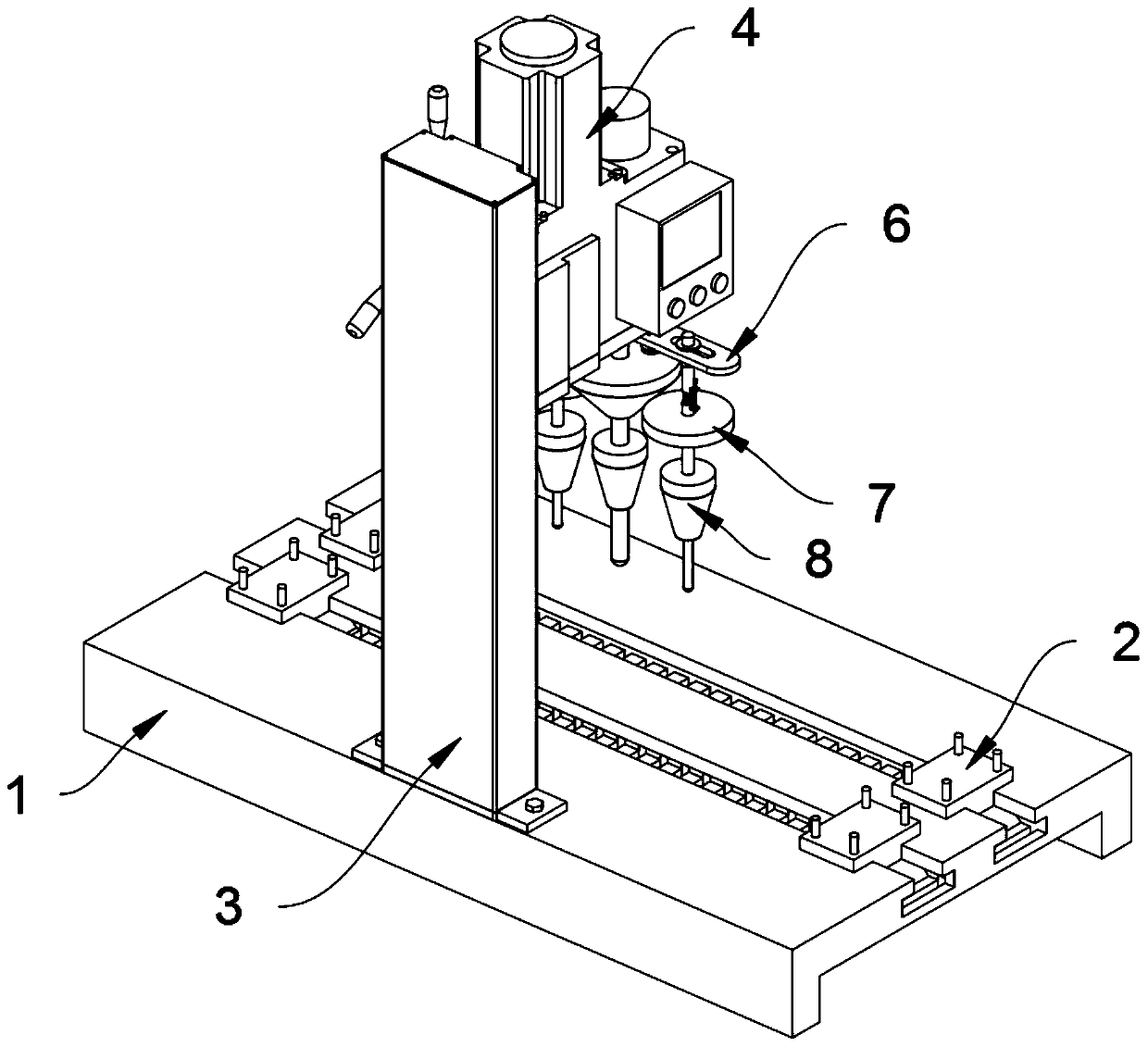

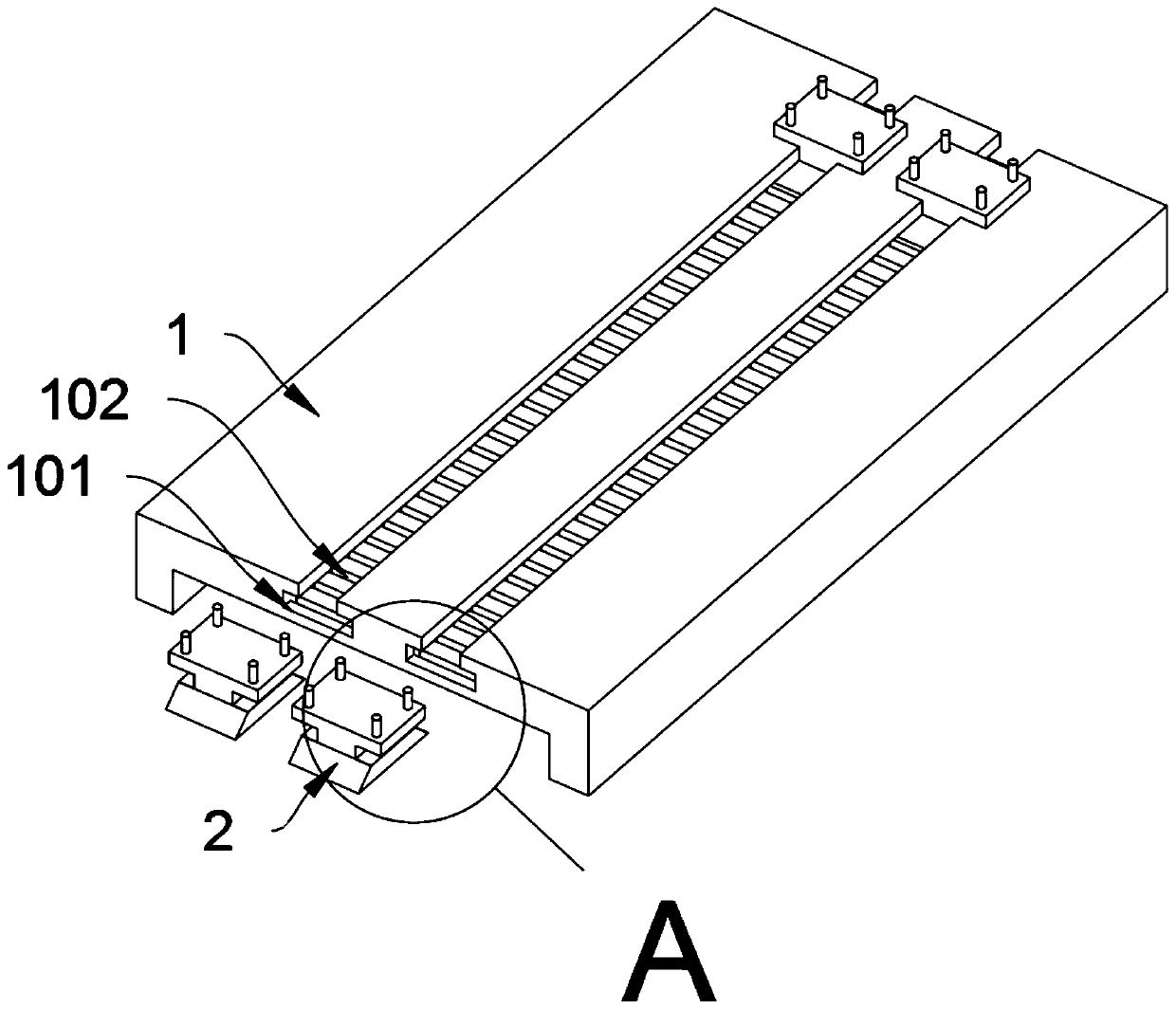

[0035] as attached figure 1 To attach Figure 9 Shown:

[0036] The invention provides a bench drilling equipment for multi-station machining without loading and unloading drill bits, which includes a base structure 1; four clamp fixing seats 2 are slidably connected to the base structure 1, and the rear center position of the top surface of the base structure 1 is passed through a bolt A sliding track 3 is fixedly connected; the sliding track 3 is provided with a drilling rig main body 4, and the bottom surface of the drilling rig main body 4 is fixedly connected with a mounting plate 5 by bolts; the mounting plate 5 is rotatably connected with two adjustment structures 6, and each A transmission structure 7 is rotatably connected to the adjustment structure 6; refer to as Figure 6, the adjustment structure 6 includes a main body plate 601, an adjustment hole 602, an adjustment seat 603, an adjustment seat fastening nut 604 and a positioning bolt 605, the main body plate 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com