Bench drilling equipment for multi-station machining without loading and unloading drill bits

A multi-station, machining technology, used in metal processing equipment, drilling/drilling equipment, metal processing machinery parts, etc., can solve problems such as fixture stuck, increased limitations, rigid structure, etc., to reduce work consumption. , the effect of reducing the chance of the residue getting stuck

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

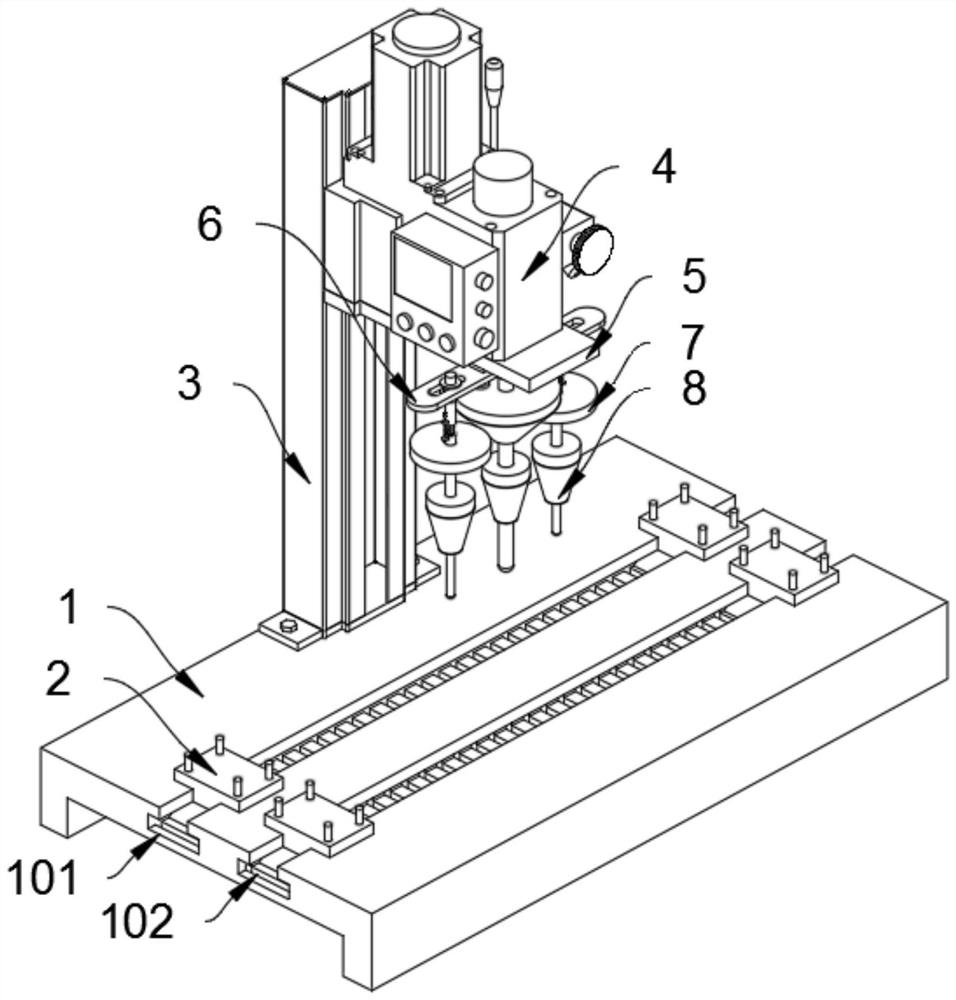

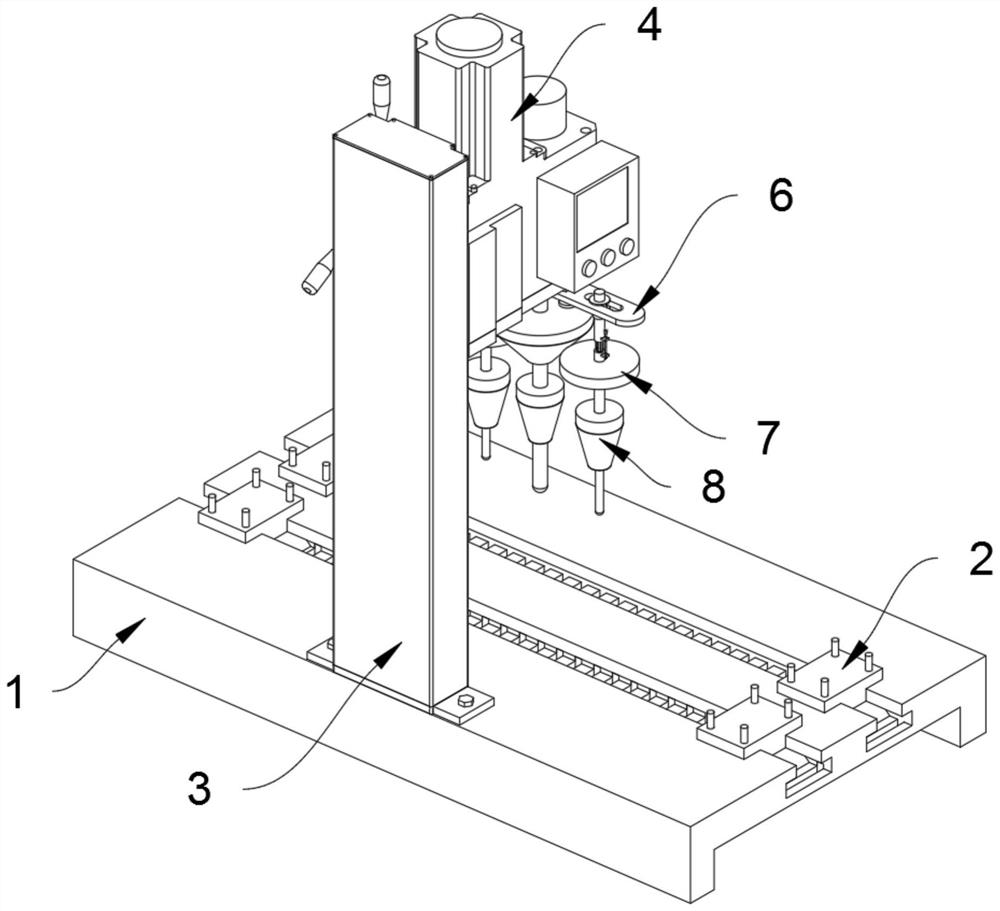

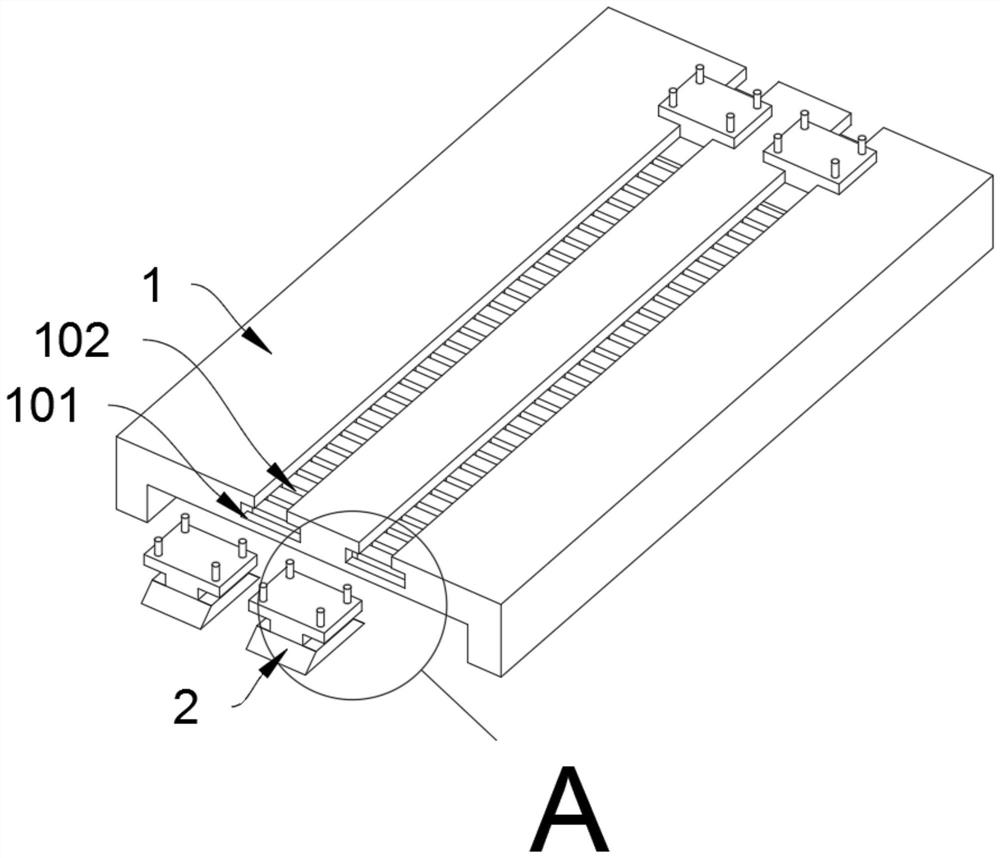

[0035] as attached figure 1 to attach Figure 9 Shown:

[0036] The invention provides a bench drilling equipment for multi-station machining without loading and unloading drill bits, which includes a base structure 1; four clamp fixing seats 2 are slidably connected to the base structure 1, and the rear center position of the top surface of the base structure 1 is passed through a bolt A sliding track 3 is fixedly connected; the sliding track 3 is provided with a drilling rig main body 4, and the bottom surface of the drilling rig main body 4 is fixedly connected with a mounting plate 5 by bolts; the mounting plate 5 is rotatably connected with two adjustment structures 6, and each A transmission structure 7 is rotatably connected to the adjustment structure 6; refer to as Image 6, the adjustment structure 6 includes a main body plate 601, an adjustment hole 602, an adjustment seat 603, an adjustment seat fastening nut 604 and a positioning bolt 605, the main body plate 60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com