Necking tool and necking method of filling valve

A valve and tooling technology, applied in the field of tooling design, can solve problems such as low closing efficiency, vulnerable parts, unstable valve closing quality, etc., and achieve the effects of improving closing strength, improving processing quality and efficiency, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

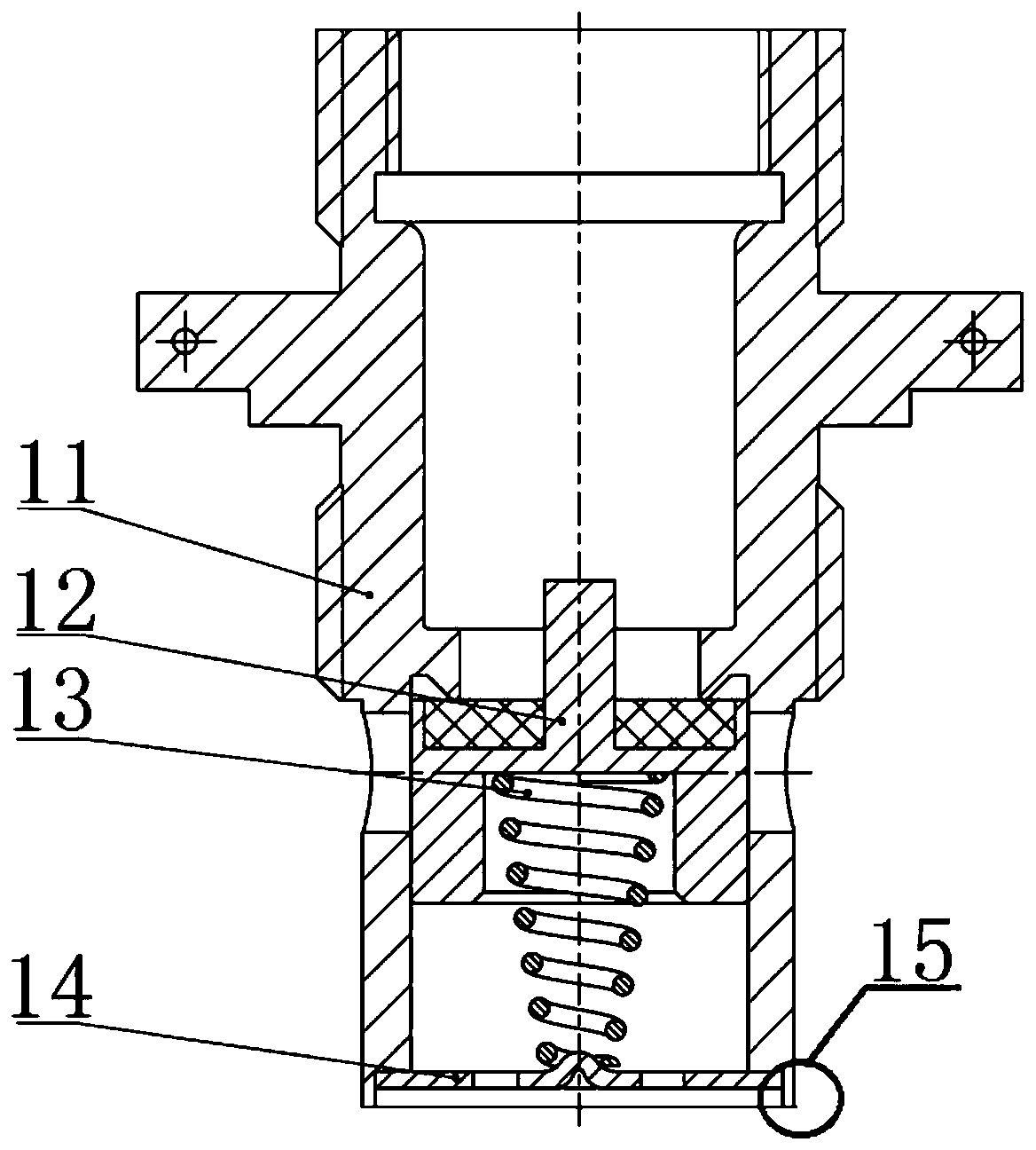

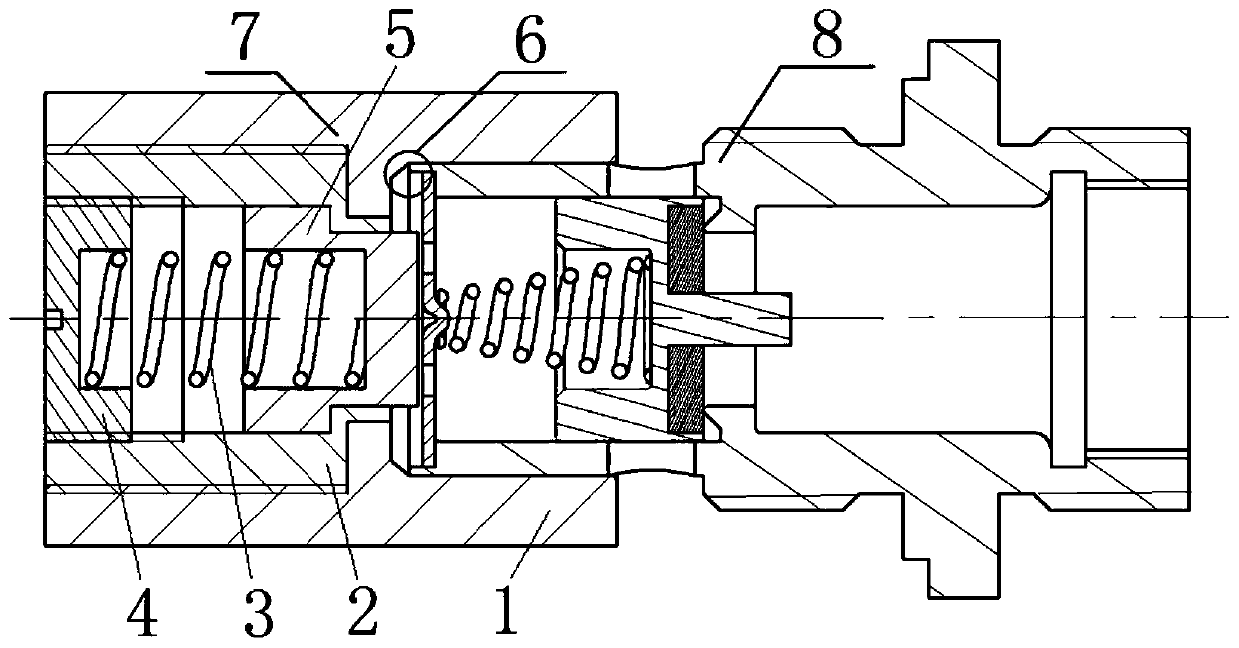

[0027] Such as figure 2 As shown, the closing tooling of the present invention includes: a pressure sleeve 1, a screw sleeve 2, a spring 3, a screw cover 4, a top block 5, etc., wherein:

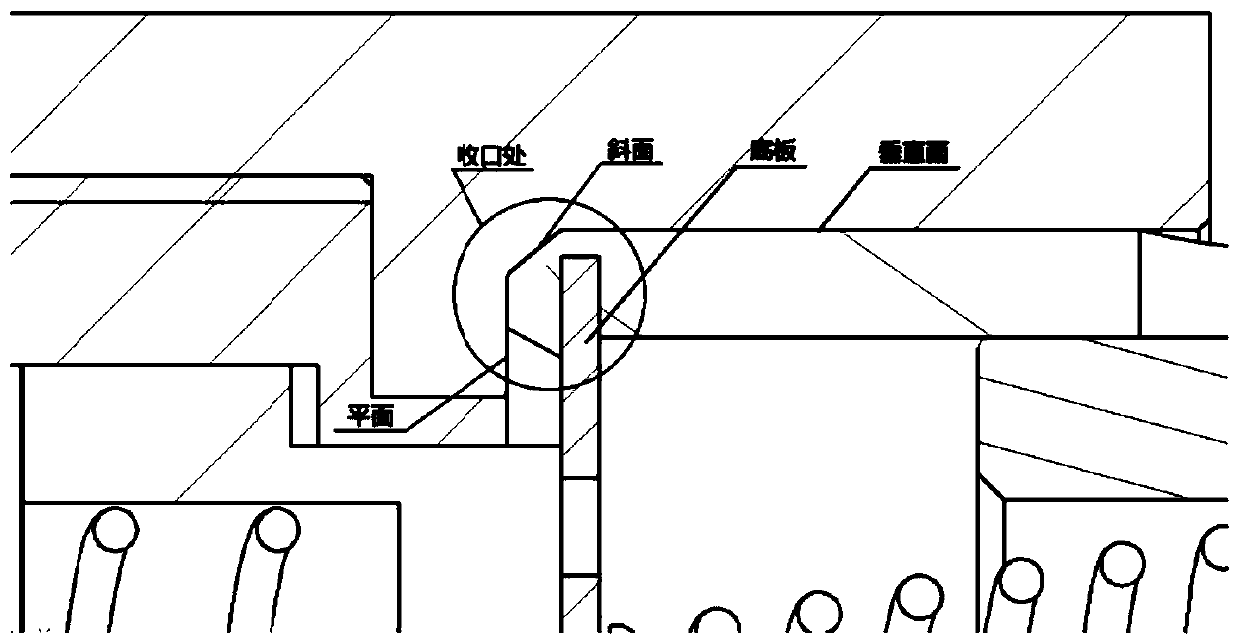

[0028] Such as image 3 with Figure 4 As shown, the pressure sleeve 1 is the main part of the entire closing tool, which is a revolving body, and the remaining components of the closing tool are installed on the left side of the inner shape to ensure that the bottom plate is close to the shell during the closing process. The right side cooperates with the closing end of the filling valve 8 shell, and sets the slope and the plane to ensure that when closing, the closing end of the shell first touches the slope, shrinks slowly, and then touches the plane to complete the closing work, ensuring that the shell is closed during the closing process. It will not deform sharply and cause breakage.

[0029] Such as Figure 5 As shown, the screw sleeve 2 is threadedly connected to the pressure sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com