Nickelbase superalloy brazing filler metal and preparation method thereof

A technology of nickel-based high-temperature alloy and brazing material, which is applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of low reliability, poor appearance quality of joints, poor corrosion resistance, etc., and achieve the purpose of inhibiting flow, welding Effects of high seam strength, excellent wettability and gap filling properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: A kind of nickel base superalloy brazing filler metal, is made up of the following components by weight percentage: Cr5.0%~20.0%, Si 4.0%~10.0%, Fe 0.1%~3.0%, Cu 0.1%~10.0% %, P 0.1% to 3.0%, the balance Ni.

[0015] The preparation method of the nickel-based superalloy brazing filler metal comprises the following steps: mixing the following components Cr, Si, Fe, Cu, P, Ni in proportion, adopting vacuum melting, gas atomization and ultrasonic sieving, and the brazing filler metal It is made into spherical powder of 240-600 meshes, and finally the solder powder is prepared into paste solder with an organic binder. Among them, P is mixed with Cr, Si, Fe, Cu, Ni in the form of Ni-P alloy.

[0016] Wherein the mass purity of above-mentioned Cr is 99.0.0%~99.9%, the mass purity of Si is 99.0.0%~99.9%, the mass purity of Fe is 99.0.0%~99.9%, the mass purity of Cu is 99.0.0% ~99.9%, the mass purity of Ni is 99.0.0% ~ 99.9%, and the mass purity of P is 99.0.0% ...

Embodiment 2

[0017] Embodiment 2: The present invention adopts to add Cu and Fe element to control unnecessary structure Ni 5 P 2 and Ni 2 The generation of P. Because Cu and Fe will compete with Ni to form corresponding phosphides, thereby reducing Ni 5 P 2 and Ni 2 The generation of P. Practice has shown that the Cu and Fe content below 0.1% can not achieve the above expected effect. When the Cu content exceeds 10.0% and the Fe content exceeds 3.0%, too much Cu and Fe will cause other problems, such as corrosion resistance Decline in performance or more susceptible to corrosion. Adding P element can improve the oxidation resistance of nickel-based solder and reduce the slag production of solder. When the P content is less than 0.1%, the effect is not obvious. When the P content exceeds 3.0%, the brittleness of the solder increases and the plasticity decreases.

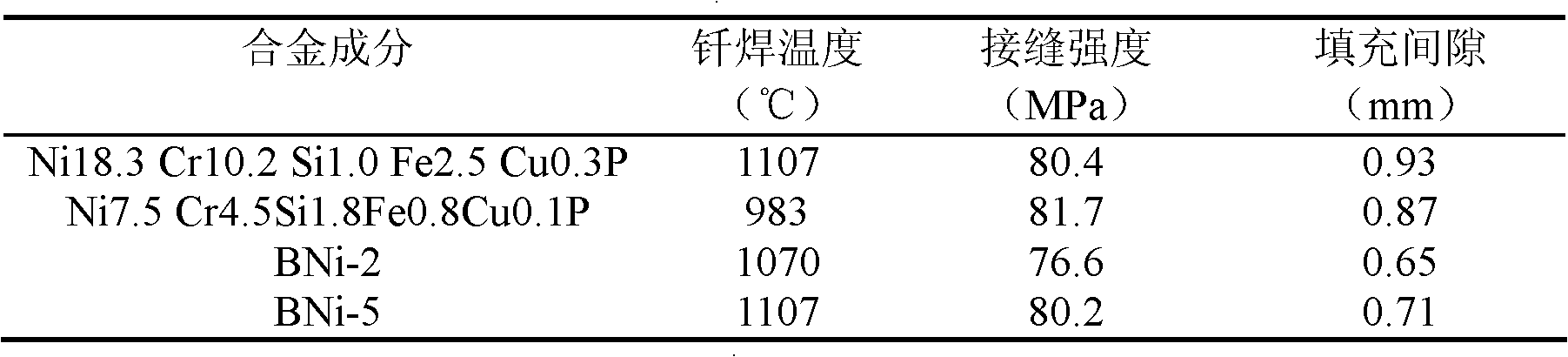

[0018] The comprehensive welding performance of the nickel-based superalloy solder of the present invention is compared...

Embodiment 3

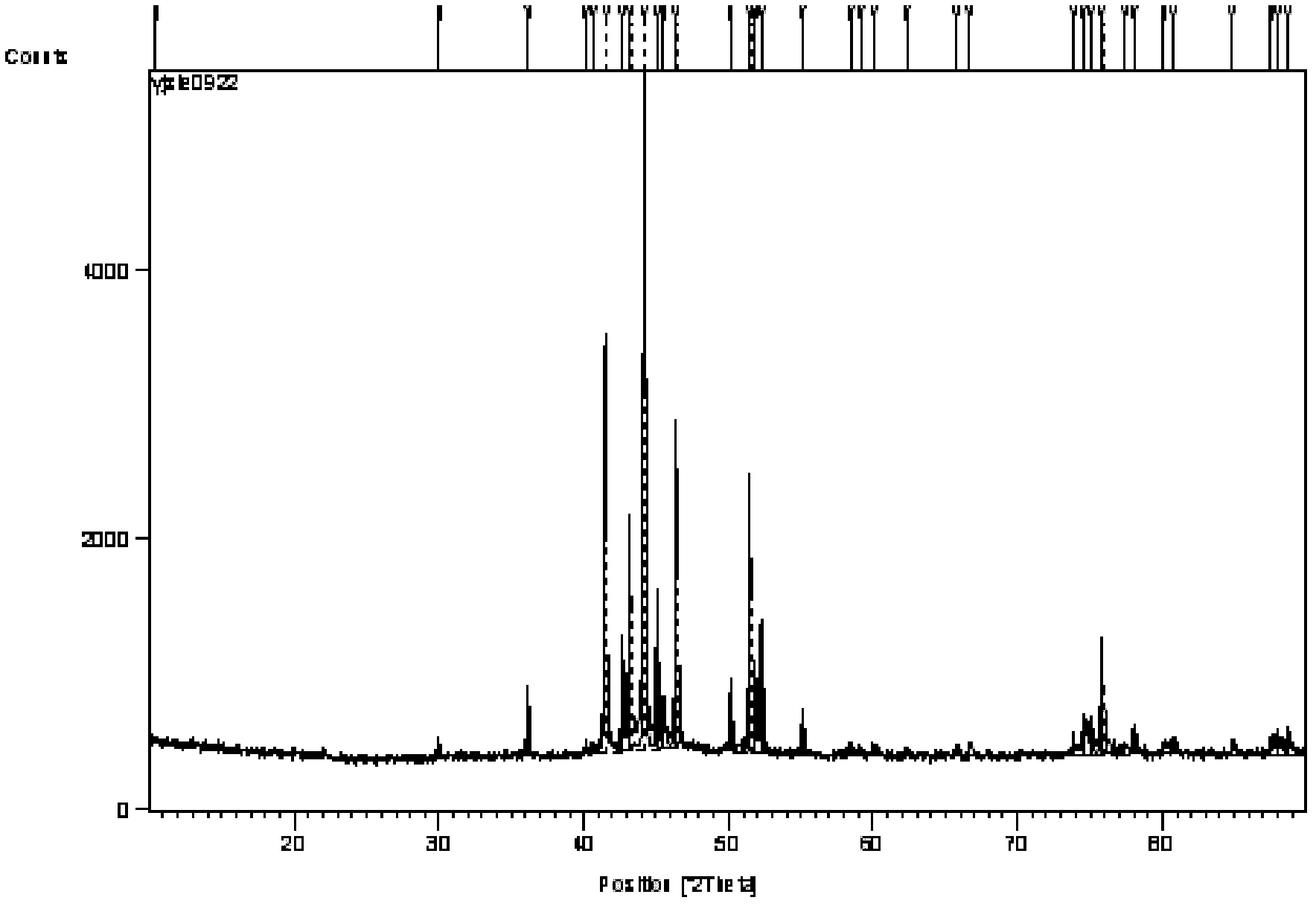

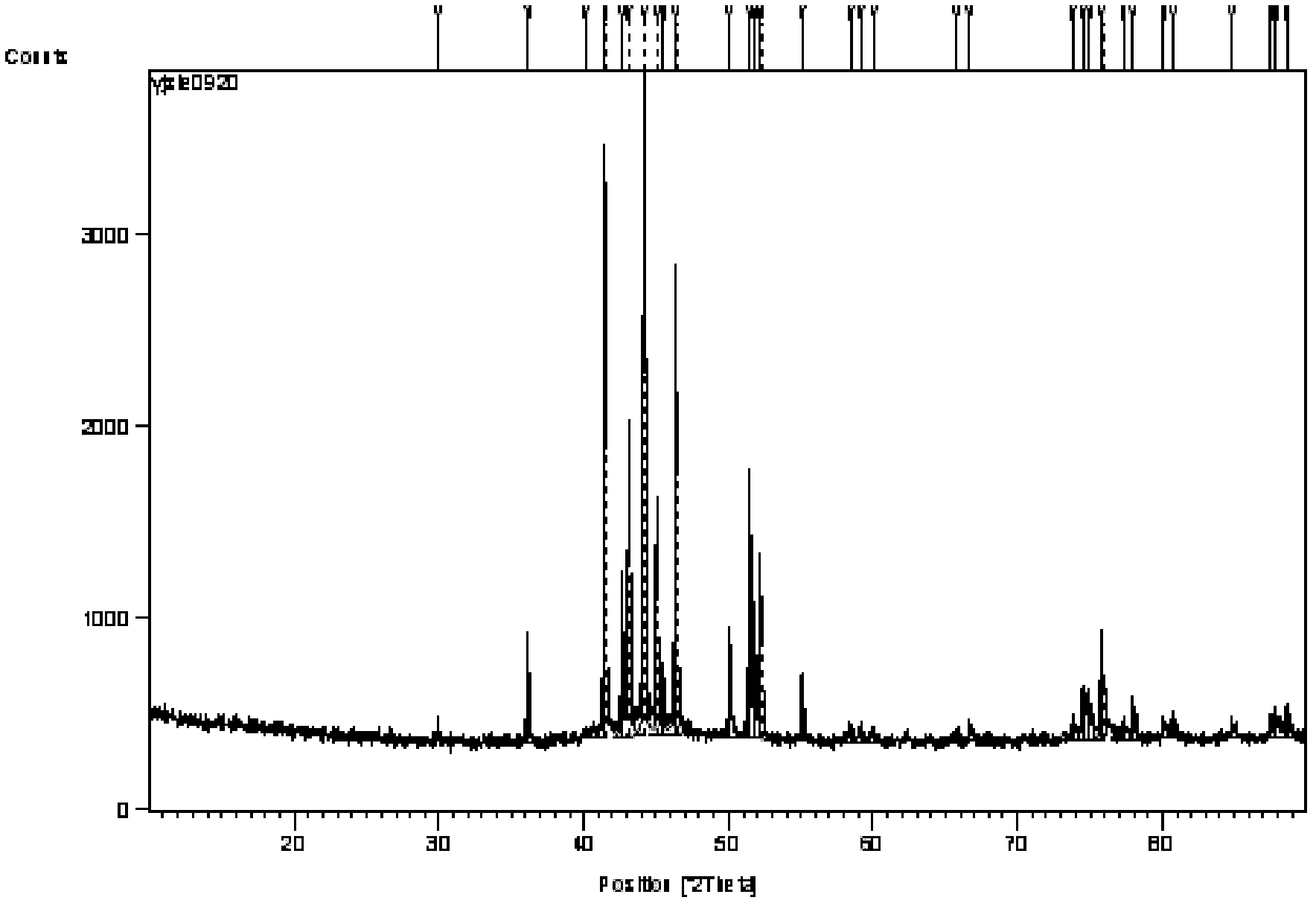

[0020] Embodiment 3: refer to figure 1 and 2 . It can be seen from the XRD pattern that the Ni5P2 and Ni2P phases in the brazing filler metal prepared by the present invention are significantly reduced after adding Cu and Fe elements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com