Coating composition for applying inkjet printing thereto to form marked preparation, preparation marked with aqueous ink, and method for producing marked preparation

A technology of composition and water-based ink, which is applied in the direction of copying/marking methods, making medicines into special physical or taking forms, printing, etc., can solve the problems of dye ink fading, achieve good ink affinity, shorten Effect of drying time, excellent gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] Next, a method for preparing a preparation marked with an aqueous ink will be described, the method comprising: a coating step of coating an object with the above-mentioned coating composition to form a coating layer; and a printing step of coating the coating layer with an aqueous ink Inkjet printing was carried out on the ink to obtain the formulation marked with aqueous ink.

[0051] The coating step in the preparation method of the aqueous inkjet-printed formulation will be described. The object to be coated is preferably a core comprising an active ingredient or a mold pin for forming a capsule. More specifically, the coating step preferably includes coating a core containing an active ingredient with the above-mentioned coating composition, or coating a mold pin for forming a capsule with the above-mentioned coating composition.

[0052] Examples of coating a core containing an active ingredient with the above coating composition will be described.

[0053] The ...

Embodiment 1

[0118] By dispersing 1.5 g of polyvinyl alcohol (the degree of saponification is 88.0 mol%, the viscosity at 20° C. determined in its 4 mass % aqueous solution is 5.30 mPa·s and is a product of Japan VAM & PVA Co., Ltd.) in 270 g of polyvinyl alcohol Pure water was stirred at 25° C. with a stirrer (laboratory stirrer LT-400D produced by Yamato Scientific Co., Ltd.) at 560 rpm for 2 minutes, and then polyethylene was dissolved in pure water and stirred at 60° C. at 560 rpm for 6 Minutes, an aqueous solution of polyvinyl alcohol was prepared.

[0119] While stirring the polyvinyl alcohol aqueous solution at 560 rpm at 80° C. with a stirrer (laboratory stirrer LT-400D produced by Yamato Scientific Co., Ltd.), 28.5 g of HPMC (methoxy group content: 28.8% by mass, The hydroxypropoxy group content is 8.8% by mass, and the viscosity at 20°C determined in its 2% by mass aqueous solution is 5.91 mPa·s) is added thereto, stirred at 560 rpm at 80°C for 3 minutes to disperse therein, and ...

Embodiment 2 to 3 and comparative example 1 to 3

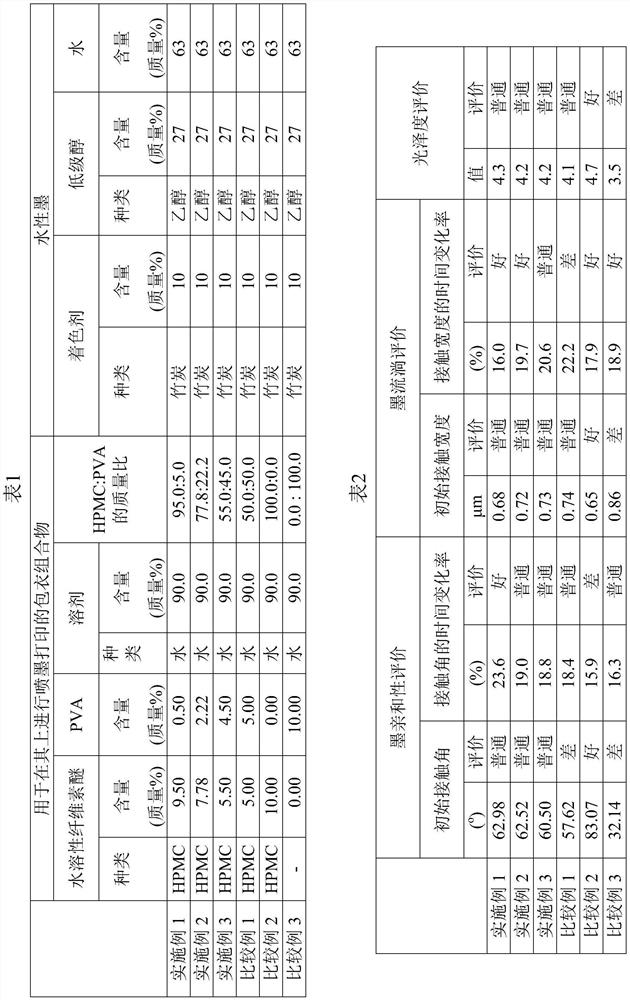

[0183] A coating composition was prepared for inkjet printing thereon to form a marked formulation, and the uncoated tablet was coated with this composition, except that the composition used for the coating formulation was changed to that described in Table 1. The coated tablets were evaluated in the same manner as in Example 1 in terms of affinity, ink bleeding and gloss except those of . The results are shown in Table 1 and Table 2.

[0184]

[0185] In each of Examples 1, 2 and 3, wherein the coating layer contains water-soluble cellulose ether and PVA in a predetermined mass ratio, the coating layer has good ink affinity, ink bleeding inhibition and good glossiness .

[0186] On the other hand, in Comparative Example 1, in which the coating layer contained water-soluble cellulose ether and PVA whose mass ratio was outside the specified range, ink affinity and gloss at the end of the measurement were good, but initial ink affinity was observed Poor compatibility and co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com