Method and structure of brazing sealing and sealing of microcircuit module housing and cover plate

A technology for microcircuits and housings, applied in circuits, electrical components, welding equipment, etc., can solve the problems of easy sputtering or flow of solder and flux into the cavity of the housing, pollution of bare chips, etc., and achieve the purpose of inhibiting solder flow, Improvement of airtightness and reduction of leakage points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

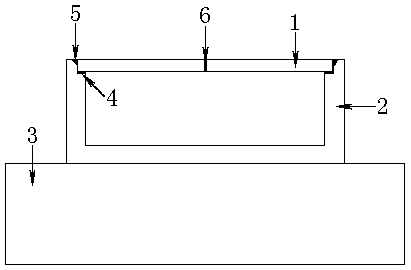

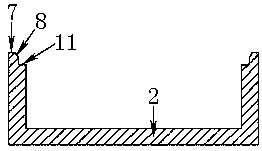

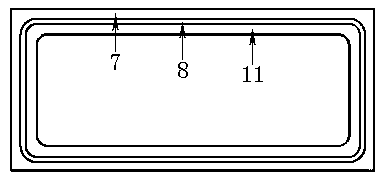

[0041] Such as figure 1 and figure 2 As shown, the cover plate 1 and the ┗-shaped casing step 11 on the casing 2 are covered on the casing 2. There is a microcircuit module in the casing 2, and a large number of bare chips are assembled in the microcircuit module. During brazing, the shell 2 is placed on the hot table 3 . A Y-shaped groove 8 is formed on the top 7 of the housing, and a ┗-shaped housing step 11 is provided below the Y-shaped groove 8 . When the cover plate 1 is closed on the ┗-shaped shell step 11 of the shell 2 , the Y-shaped groove 8 forms an annular groove gap between the cover plate 1 and the shell 2 . This is conducive to the flow of solder during brazing, making the brazing joint plump, improving the sealing performance, and effectively reducing the generation of leakage points. At the same time, the annular groove formed by the Y-shaped groove 8 can also prevent the solder from overflowing. effect.

[0042] Such as figure 1 and Figure 5 As shown,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com