Crankshaft connecting rod positioning and pressing structure in electric actuator pull rod adjusting structure

A technology of electric actuators and crankshaft connecting rods, applied in hand-held tools, manufacturing tools, etc., can solve the problems of small space range, difficult installation, large assembly errors, etc., and achieve simple and reasonable structural design, good positioning and pressing effect, The effect of meeting the needs of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0018] Example.

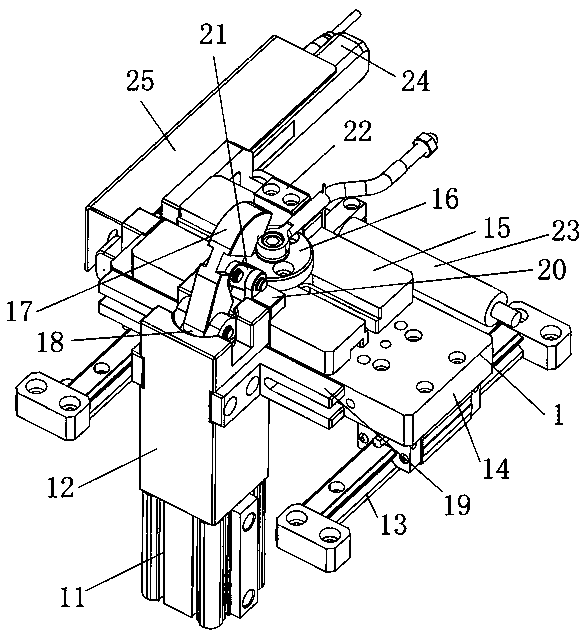

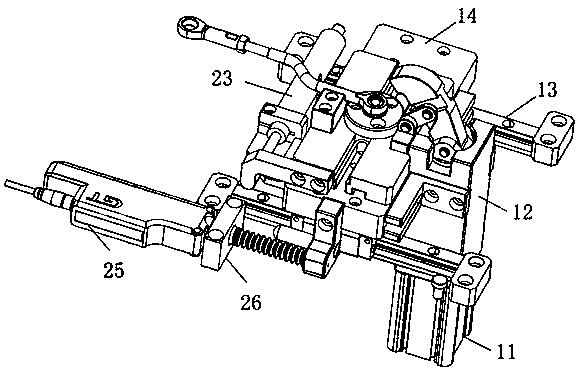

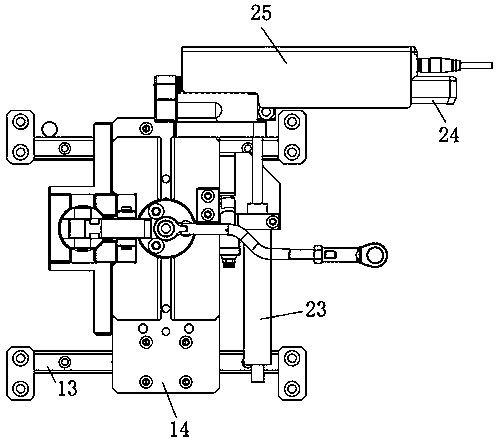

[0019] see Figure 1 to Figure 3 The crankshaft connecting rod positioning and pressing structure in the pull rod adjustment structure of the electric actuator in this embodiment includes a crankshaft connecting rod positioning and pressing mechanism 1, and the crankshaft connecting rod positioning and pressing mechanism 1 includes a crankshaft connecting rod positioning and pressing cylinder 11 and a cylinder seat 12. , guide rail 13, sliding seat 14, adjusting seat 15, positioning seat 16, pressing head 17, connecting rod 18, fixed block 19, V-shaped block 20 and connecting rod 21, and the crankshaft connecting rod positioning pressing gas 11 cylinder is fixed on On the cylinder block 12, the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com