A turnover device based on bearing processing

A technology of bearing processing and top plate, which is applied in the field of bearing processing, can solve the problems of shaft material collision damage, boring operation, inconvenient processing, etc., and achieve the effects of reducing collision damage, improving stability, and safe and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

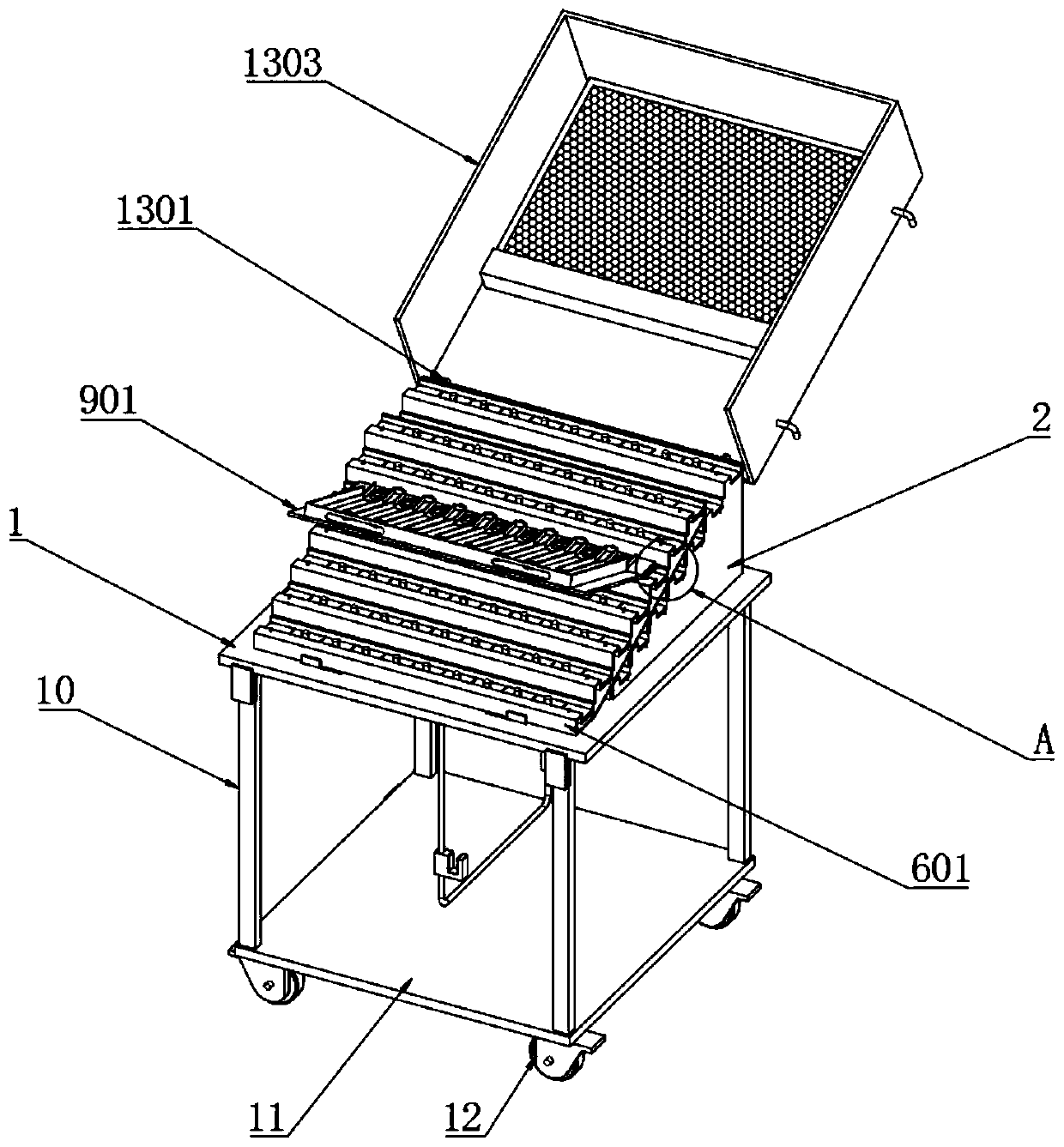

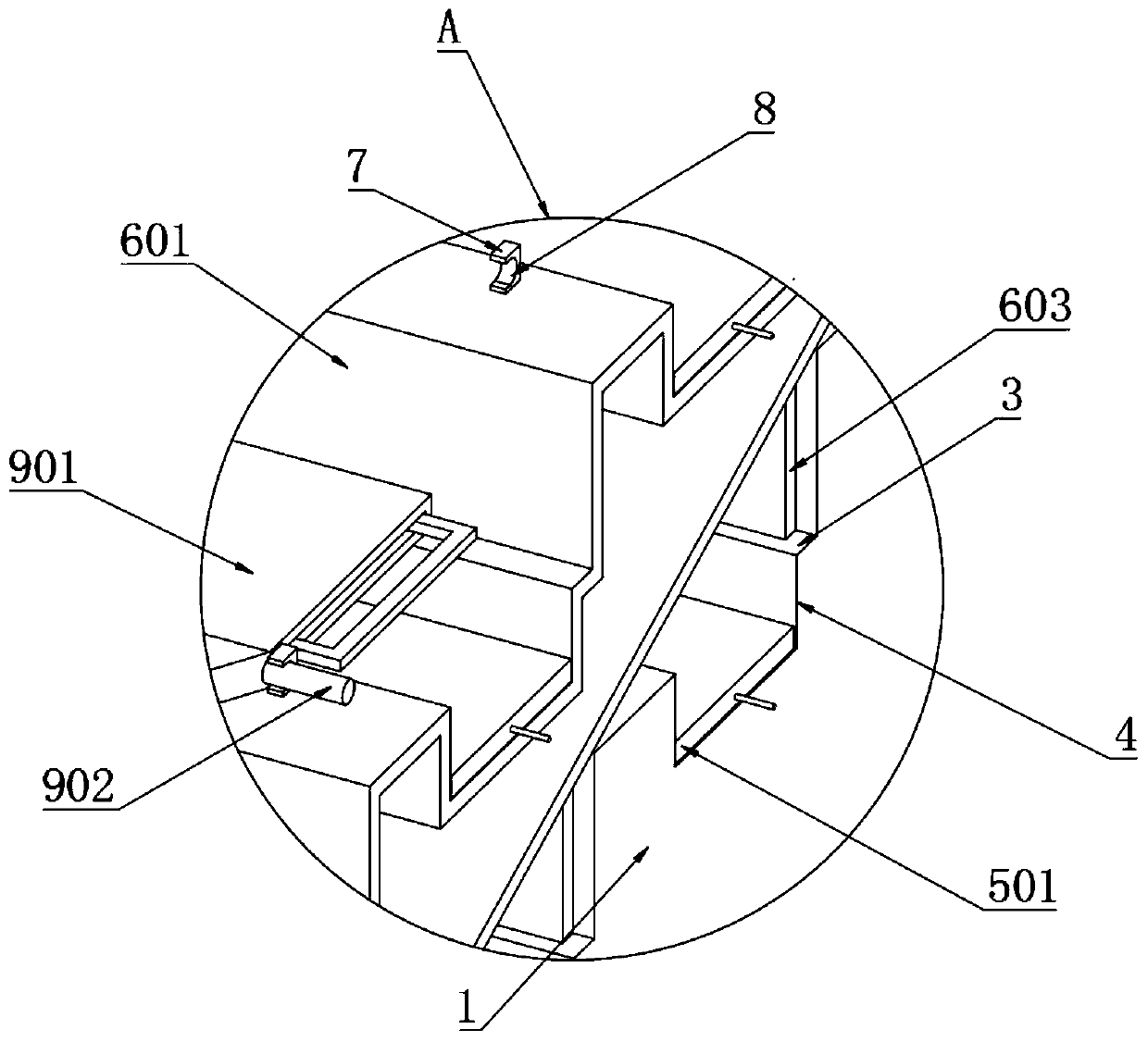

[0053] Example: such as Figure 1-11 As shown, the present invention provides a technical solution, a turnover device based on bearing processing, including a top plate 1, a support column 10 is welded at each corner position of the bottom end of the top plate 1, and a bottom plate 11 is welded at the bottom end of the support column 10 , each corner of the bottom of the base plate 11 is equipped with a universal brake wheel 12, so that the device can move through the universal belt brake wheel 12, the top of the top plate 1 is welded with a ladder 2, and the top of the ladder 2 is provided with several The first stepped surface 3, and the tops of several first stepped surfaces 3 are provided with first sinking grooves 4;

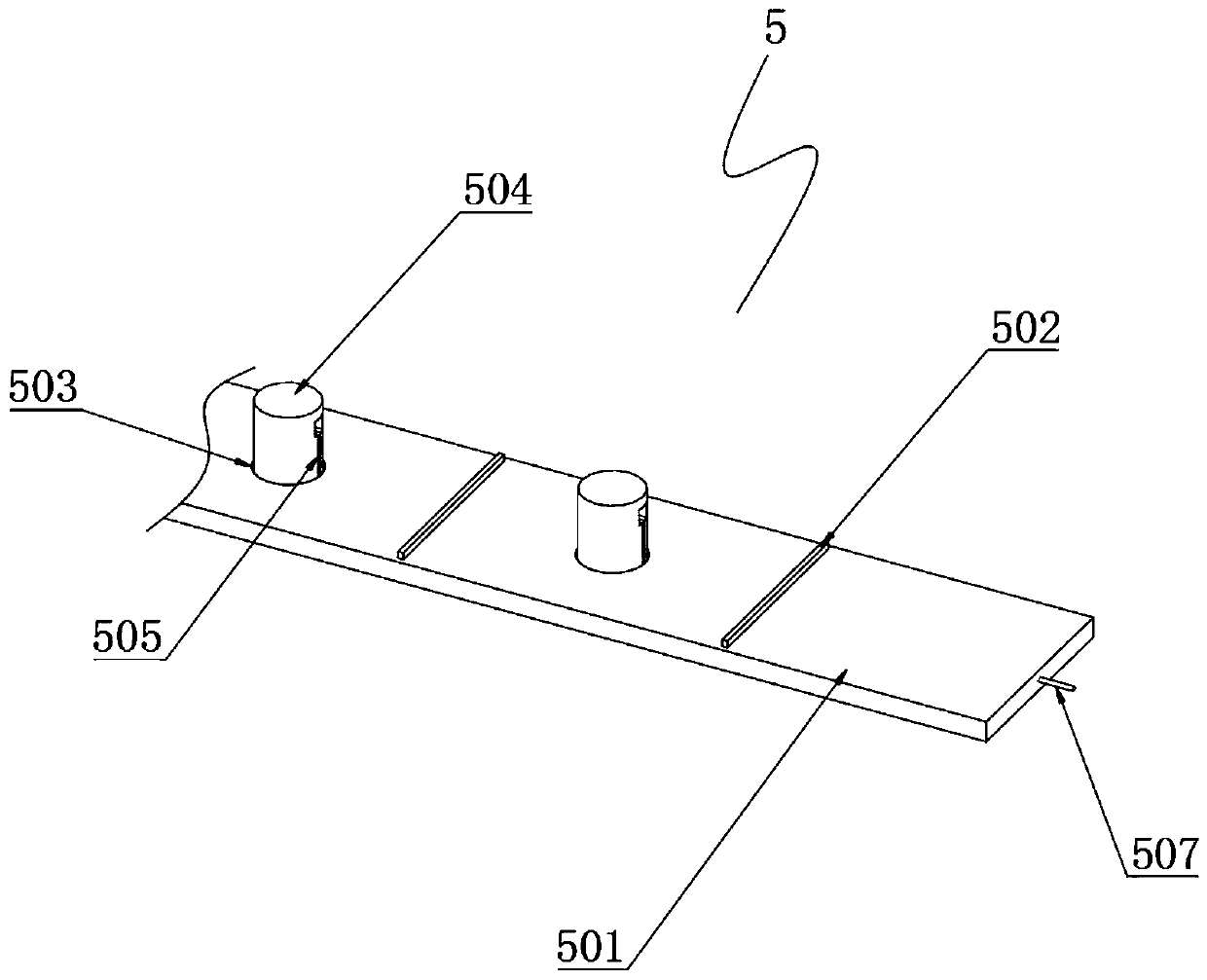

[0054] An access assembly 5 is installed inside the first sinker 4, and the access assembly 5 includes an access plate 501, a separating rubber strip 502, a sliding through hole 503, a limit post 504, a slideway 505, an overturning chamber 506, and an adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com