Plastic crushing and melting integrated machine

An all-in-one machine and plastic technology, applied in plastic recycling, mechanical material recycling, recycling technology, etc., can solve problems such as fragility, and achieve the effect of easy processing and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0025] The technical scheme adopted in the present invention is:

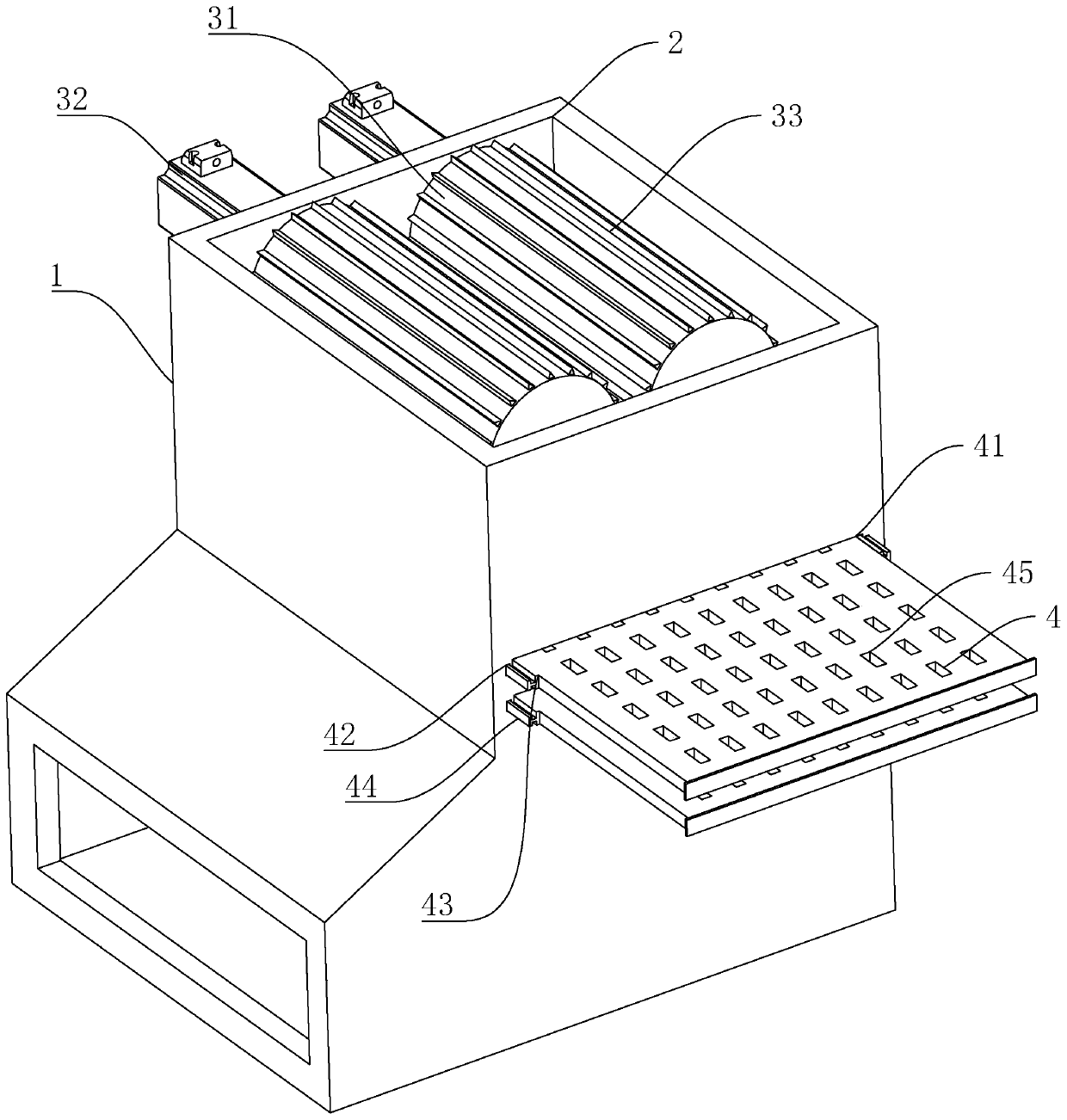

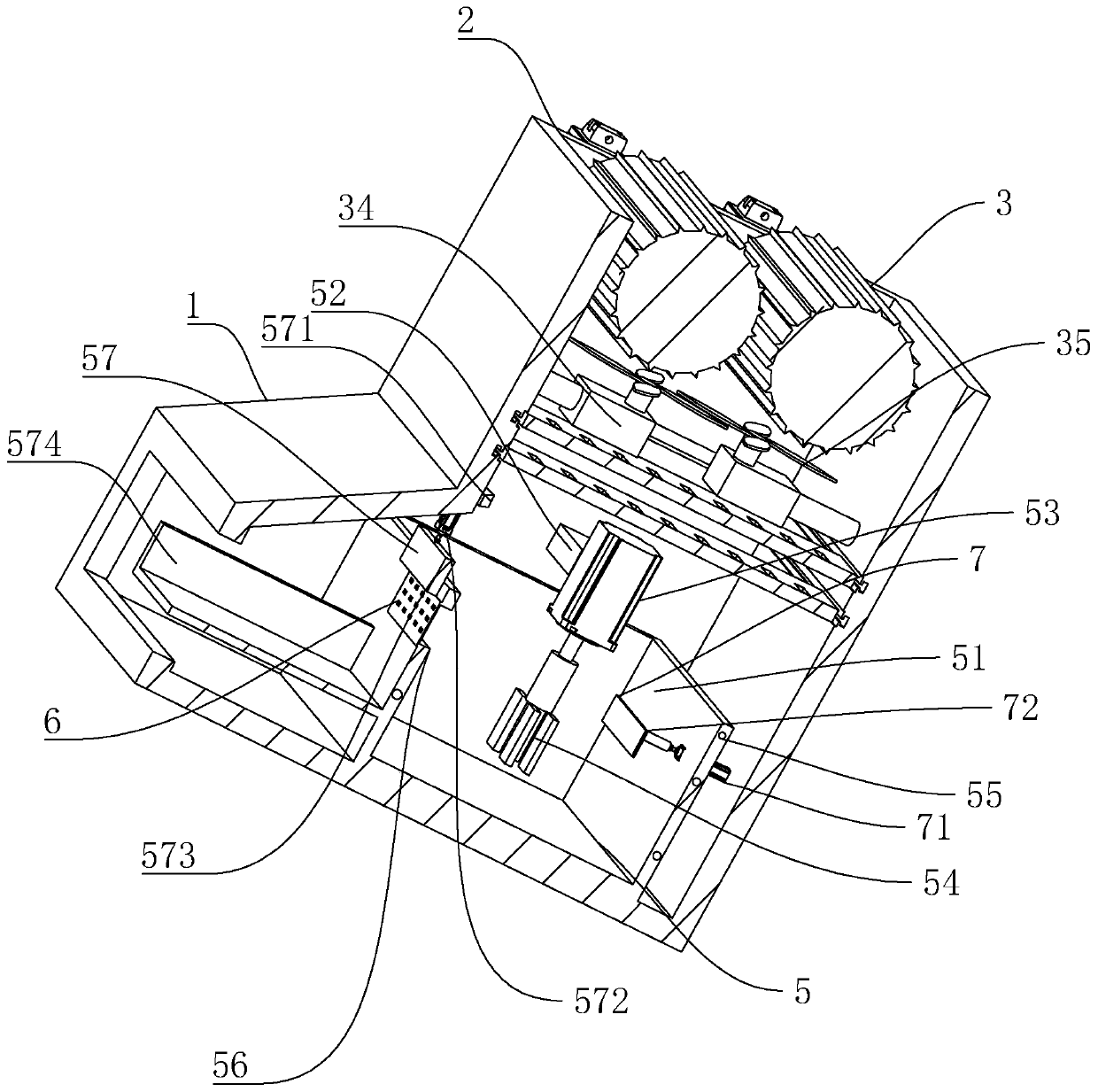

[0026] A plastic crushing and melting machine, such as figure 1 and figure 2 As shown, it includes a body 1, the top of the body 1 is provided with a feed inlet 2, and the feed inlet 2 is provided with a crushing device 3. The crushing device 3 includes a rotating roller 31 arranged on the inner wall of the feed inlet 2. There is a rotating motor 32 connected to the rotating roller 31, and the surface of the rotating roller 31 is provided with barbs 33, which is convenient for squeezing and crushing the plastic. 35, so that after the plastic is crushed and extruded, it is smashed and knocked off by the rotating blade. The bottom of the crushing device 3 is provided with a filtering device 4, and the filtering device 4 includes an opening 41 provided on the side wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com