Automatic loading device

A technology of automatic loading and equipment, applied in the directions of transportation and packaging, loading/unloading, etc., can solve the problems of inconvenience and a lot of time, and achieve the effect of easy loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

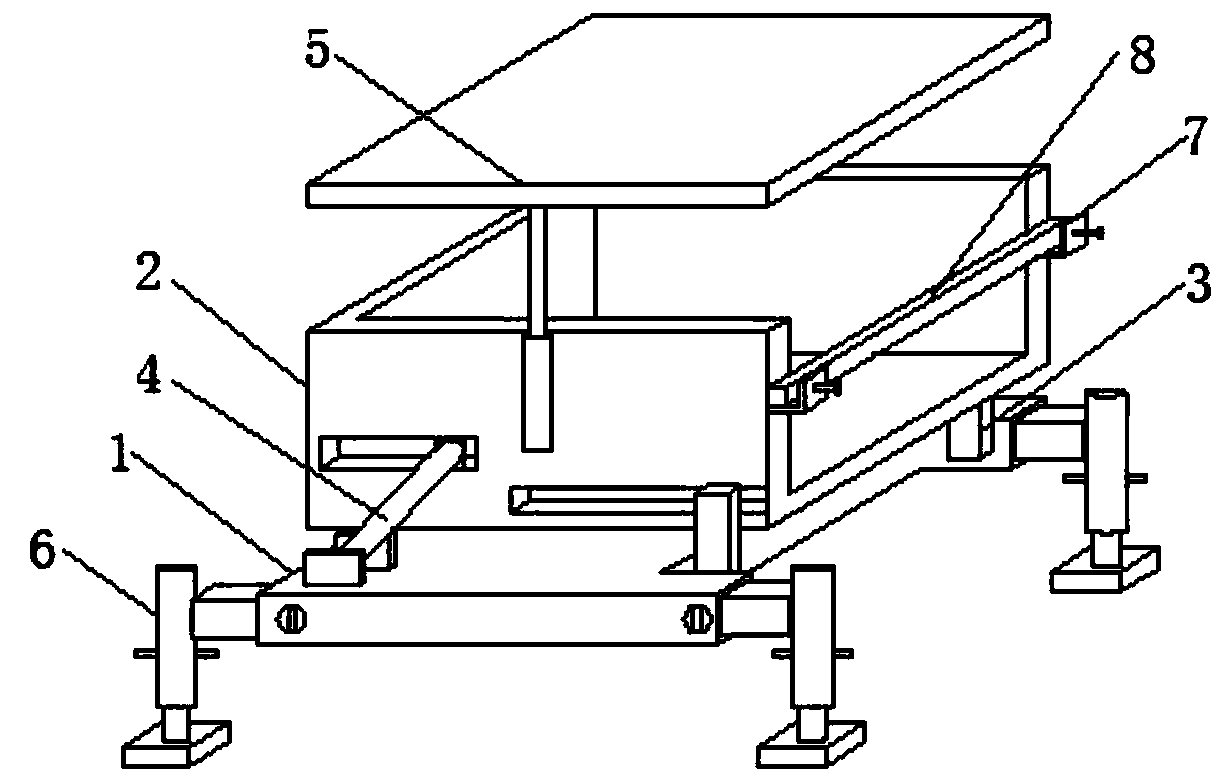

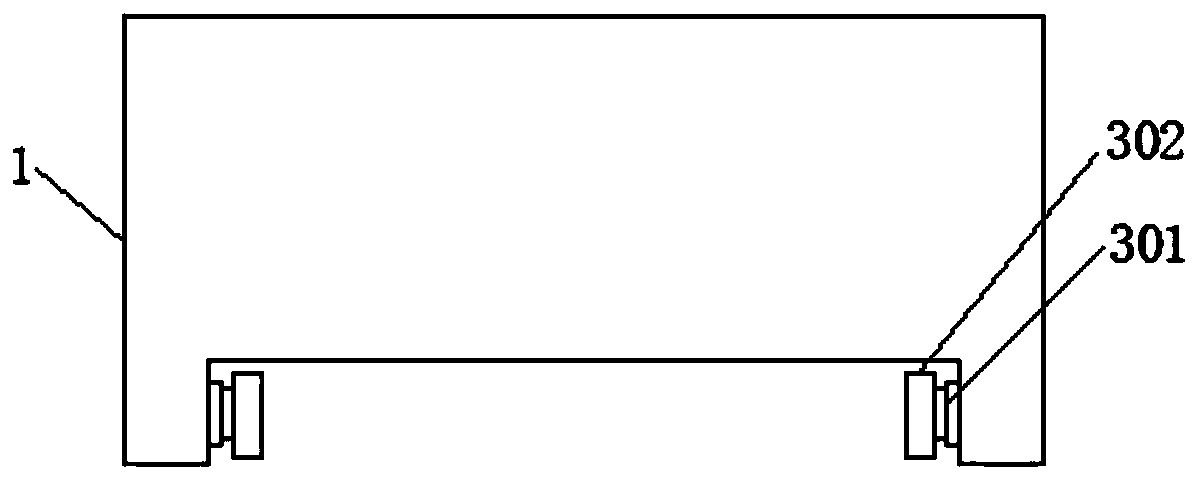

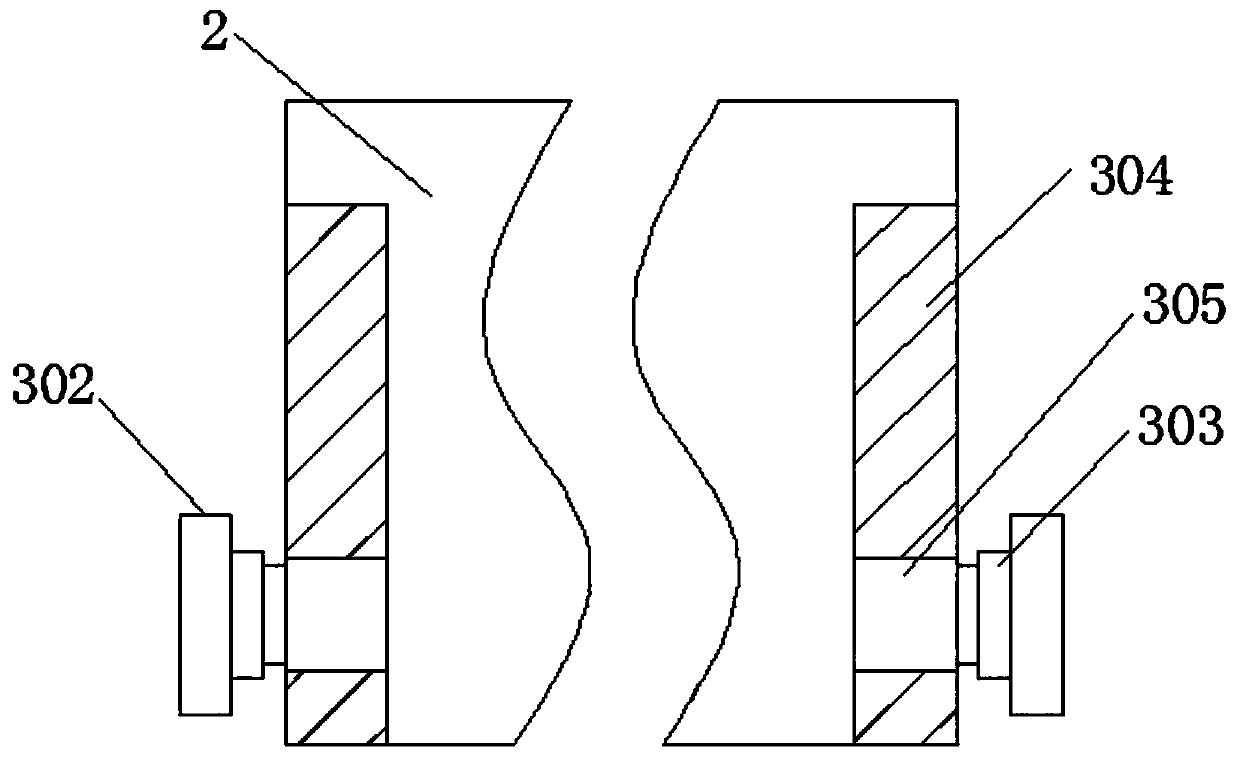

[0040] Embodiment 1: as figure 1 — Figure 8 , an automatic charging device, comprising: a base 1, a charging box 2 is installed on the top of the base 1, and a stop rod 8 is installed on one side of the charging box 2, and an opening is provided on one side of the charging box 2, When the material box 2 is overturned, the opening is attached to the ground, and grooves are opened around the base 1;

[0041] The top of the charging box 2 is equipped with a clamping mechanism 5, and the inside of the clamping mechanism 5 includes a first hydraulic rod 501, and is fixedly connected between the first hydraulic rod 501 and the charging box 2, and the first hydraulic rod 501 A pressing plate 502 is fixedly connected to the top of the pressing plate 502, and a rubber plate 503 is connected to the bottom end of the pressing plate 502. The rubber plate 503 can prevent the goods from being damaged when the goods are clamped;

[0042] The inside of the base 1 is equipped with a rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com