Method for improving miscellaneous fill and improving backfill quality of composite foundation

A composite foundation and miscellaneous filling technology, which is applied in the fields of filling, soil protection, infrastructure engineering, etc., can solve the problems of complex treatment methods of treatment equipment, and achieve the effects of improving convenience, reducing costs, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] It includes the following steps:

[0028] G. Survey the construction site and clean up the construction site;

[0029] H. After clearing the table, the construction area is positioned and set out;

[0030] I. Excavate the foundation to the design depth with miscellaneous filling soil processing machinery;

[0031] J. Manually sort out the miscellaneous filling soil excavated from the original foundation to remove the sundries;

[0032] K. Use the miscellaneous fill processing machine to crush and screen the miscellaneous fill soil from which the sundries have been removed.

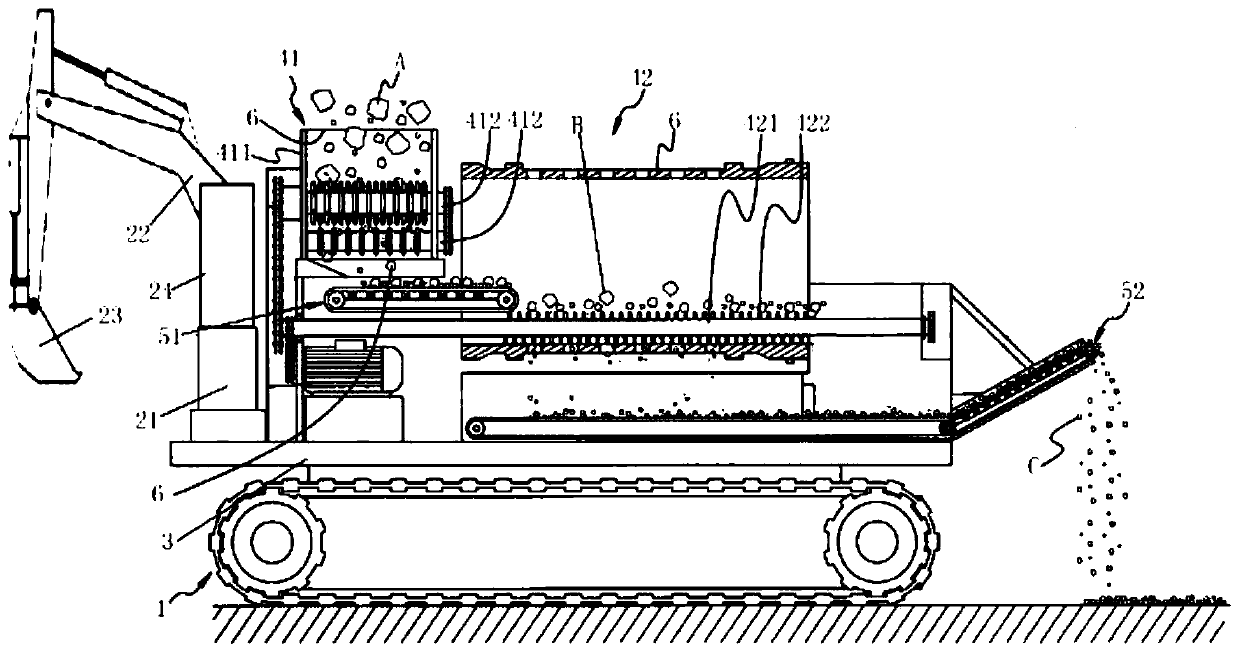

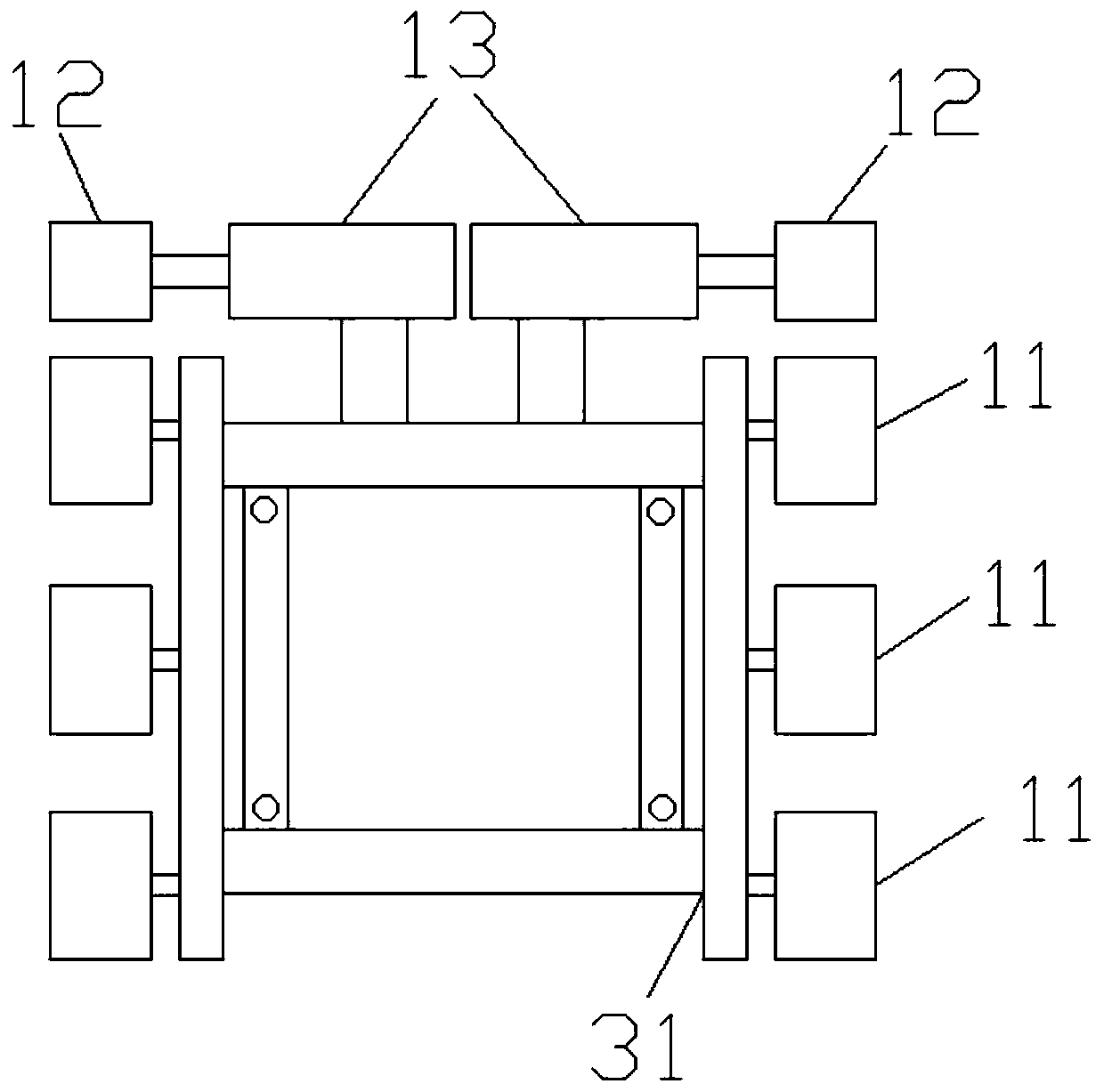

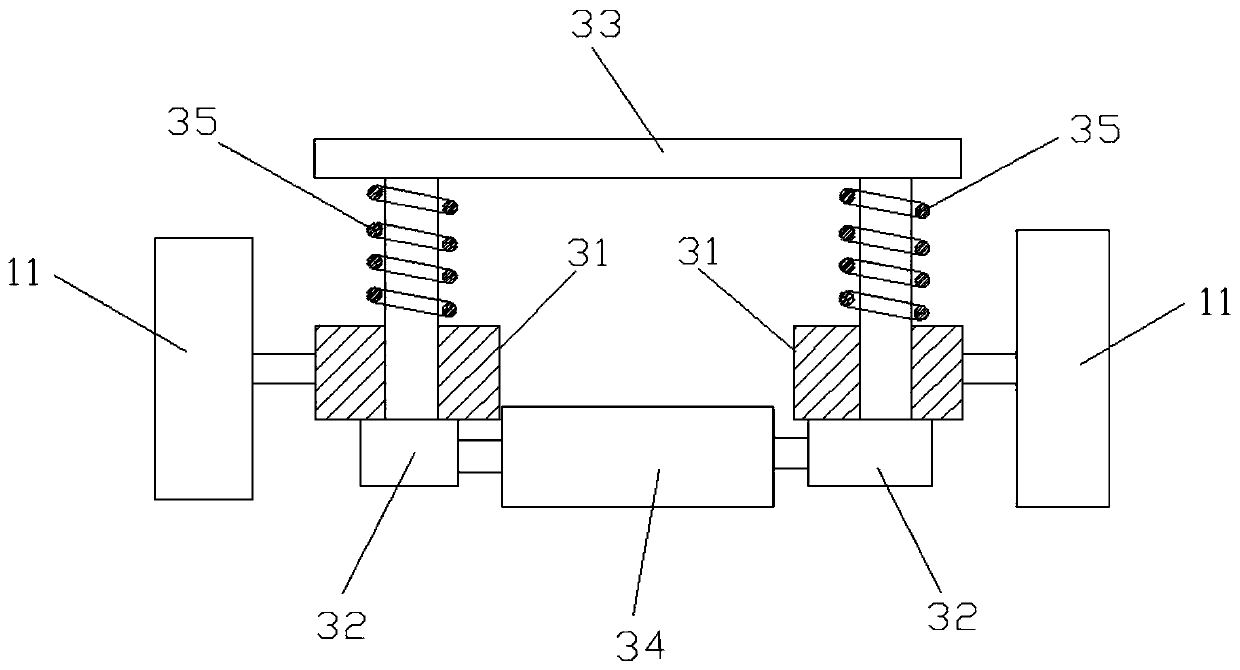

[0033]Pour the crushed and screened miscellaneous fill into the excavated foundation, and compact the construction site; the specific structure of the miscellaneous fill processing machine is: it includes a crawler belt 1 for moving, and The middle part of the crawler belt 1 is provided with an installation platform 3, and the installation platform 3 is provided with a loading mechanism and a cru...

Embodiment 2

[0041] This embodiment is a comparative benchmark test

[0042] Before the excavation of the foundation, the surface cleaning of the construction area should be completed first.

[0043] After cleaning the table, the construction area is positioned and laid out, and the foundation is mechanically excavated to the design depth.

[0044] The plain soil (filler 1 for short, excluding construction waste and sundries) is transported out for foundation backfilling.

[0045] The moisture content of the tested plain soil is 13.7%, which is equal to the optimal moisture content corresponding to the maximum dry density measured in the laboratory, and meets the construction conditions (the construction moisture content range is the optimal moisture content ± 2%, the same below).

[0046] Backfill the foundation in 6 layers, and the thickness of each layer of backfill paving is 30cm.

[0047] Use a 20-ton vibratory road roller, press the initial static pressure once, after the backfill ...

Embodiment 3

[0050] Before the excavation of the foundation, the surface cleaning of the construction area should be completed first.

[0051] After cleaning the table, the construction area is positioned and laid out, and the foundation is mechanically excavated to the design depth.

[0052] The miscellaneous fill soil excavated from the original foundation is mainly composed of large pieces of construction waste and mixed soil with a maximum particle size of less than 7cm (original soil and small particle construction waste) after manual selection and removal of sundries.

[0053] It has been confirmed that the bulk construction waste contains 64.5% red bricks and 35.5% concrete. The mixed soil contained 15.9% of broken bricks and 3.5% of mortar blocks with a particle size of 5 mm or more.

[0054] Use the miscellaneous filling soil processing machine to crush and screen the miscellaneous filling soil from which impurities have been removed into qualified backfill (filler 2 for short). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com