Tempered glass partition mounting structure and method

A technology of tempered glass and installation structure, which is applied in the direction of building components, building structures, walls, etc. It can solve the problems that the base structure is not strong enough, the base layer requirements are not high, and affect the construction efficiency, so as to shorten the construction period, improve the lighting, The effect of eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

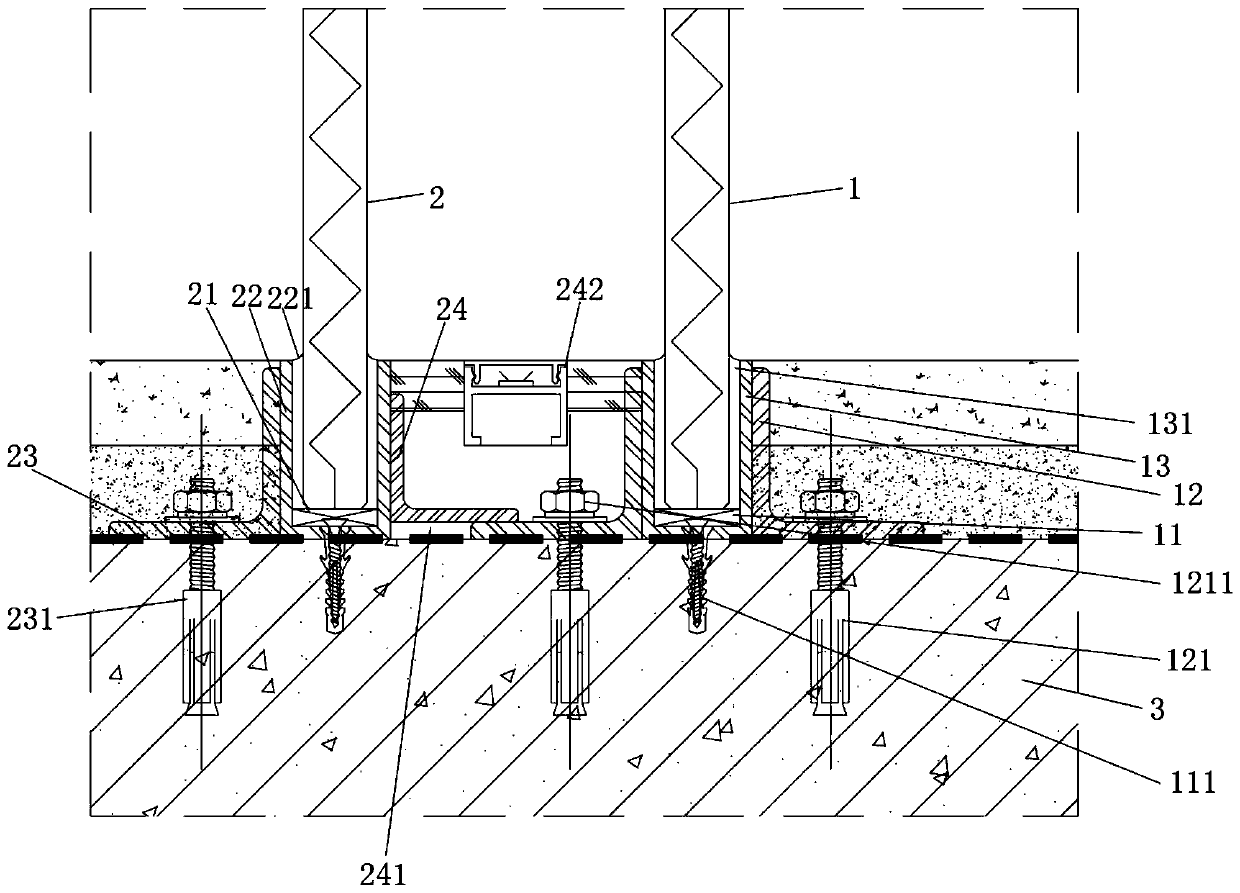

[0029] see figure 1 , the figure shows a tempered glass partition installation structure provided by Embodiment 1 of the present invention, which includes a first tempered glass 1 and a second tempered glass 2, the bottom of the first tempered glass 1 is fitted with a glass clamp 11 (specifically The cross-section is a U-shaped strip), the bottom of the glass clamp 11 is fixedly connected to the building ground 3, and the outer and inner sides of the first tempered glass 1 are respectively provided with two first steel plates 12, and the first steel plates 12 are fixedly connected to the building. On the ground 3, the bottom of the first tempered glass 1 is sandwiched between two first steel plates 12, a cavity 4 is left between the second tempered glass 2 and the first tempered glass 1, and the inner side of the first tempered glass 1 faces the void. Cavity 4, the bottom of the second tempered glass 2 is fitted with an elastic glass clip 21 (specifically a U-shaped strip in c...

Embodiment 2

[0042] see figure 1 , the figure shows a tempered glass partition installation structure provided by Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the third steel plate 24 is The cross-section is an L-shaped angle steel, and the cross-sectional area of the third steel plate 24 is smaller than that of the second steel plate 23 . Through the setting of the above structure, under the condition of ensuring the inner strength of the second tempered glass, the weight burden on the inner side of the second tempered glass can be reduced, thereby facilitating the fine adjustment of the distance between the second tempered glass and the first tempered glass.

Embodiment 3

[0044] see figure 1 , the figure shows a tempered glass partition installation structure provided by Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the third steel plate 24 The bottom rests on the bottom of the first steel plate 12, and a space is formed between the bottom surface of the third steel plate 24 and the building ground 3, and an elastic rubber block 241 is arranged in the space. Through the setting of the above structure, the elastic rubber block can form a limit function for fine-tuning the distance between the second tempered glass and the first tempered glass, so as to ensure that the firmness of the second tempered glass base layer will not be affected by excessive adjustment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com