Self-adaptive sparse compression self-coding rolling bearing fault diagnosis system

A fault diagnosis system and rolling bearing technology, applied in the testing of mechanical components, the testing of machine/structural components, measuring devices, etc., can solve the problems of unknown, effective identification and analysis of fault diagnosis results, limitations of fault diagnosis results, and difficulty in quantifying fault diagnosis results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

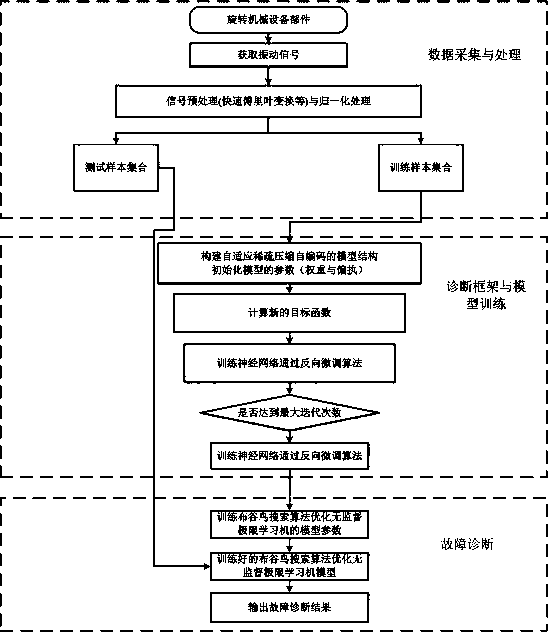

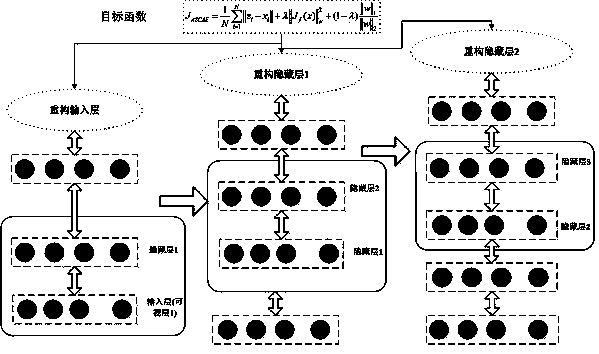

Method used

Image

Examples

Embodiment 1

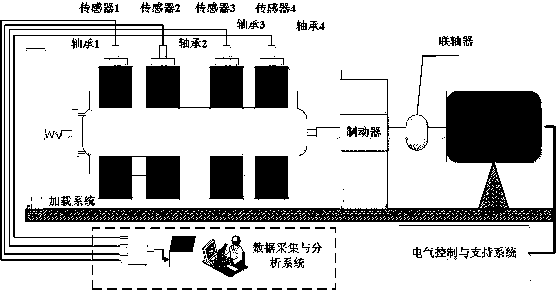

[0080] Example 1: Verification of test data of accelerated bearing life strengthening testing machine

[0081] The ABLT-1A bearing life strengthening testing machine used in this experiment is suitable for bearings with an inner diameter of Rolling bearing fatigue life strengthening test. image 3 Schematic diagram of the structure of the bearing life strengthening testing machine. The testing machine is mainly composed of a test head, a test head base, a transmission system, a loading system, a lubrication system, an electrical control system, and a computer monitoring system. The test head is installed in the test head seat, the traditional system transmits the movement of the motor, and the test shaft rotates at a certain speed through the coupling; the loading system provides the load required for the test, and the lubrication system makes the test shaft fully lubricated under normal conditions. Experiment; the electrical control system provides power and electrical prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com