Lightweight high-speed maglev vehicle running part device

A running part, lightweight technology, applied in the field of maglev vehicles and high-speed maglev vehicles, can solve the problems of poor operating comfort and economy, complex design of running parts, and high manufacturing costs, so as to improve reliability and maintainability, improve Reliability and economy, effect of simplified secondary suspension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

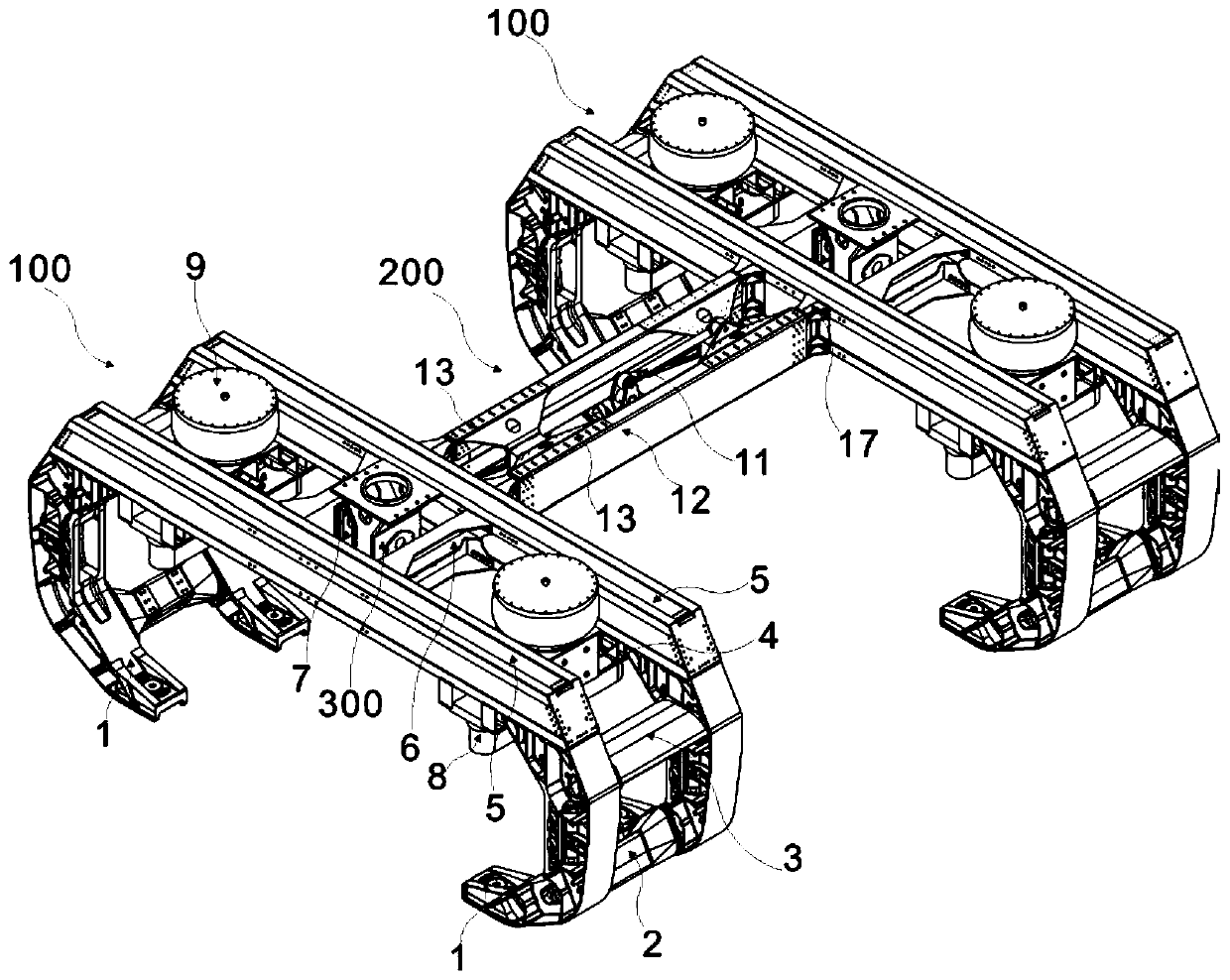

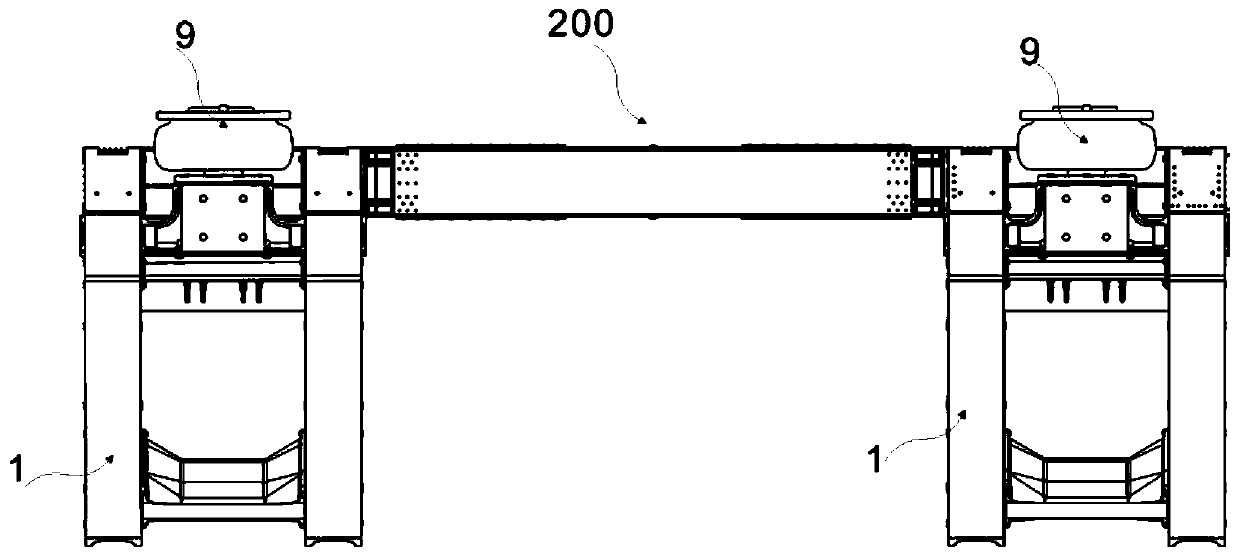

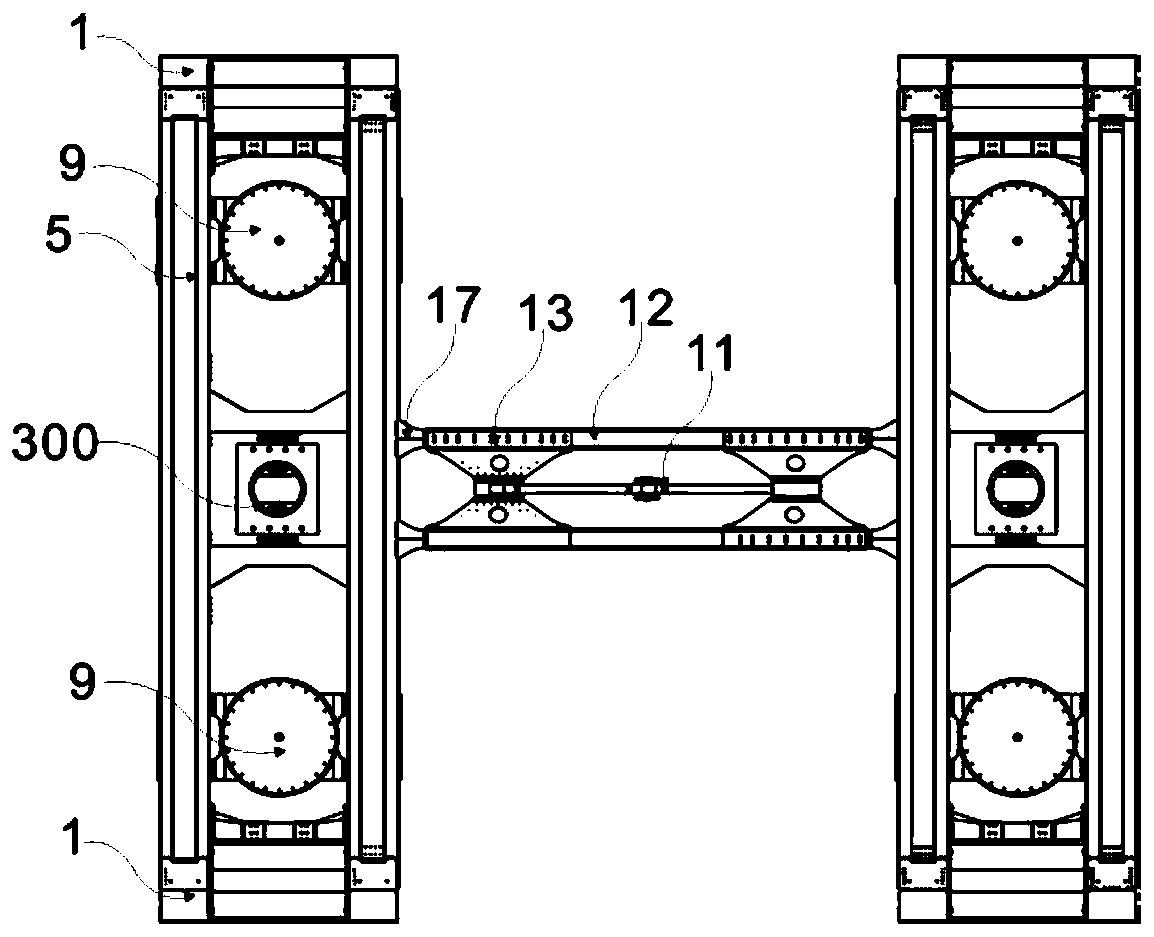

[0040] Such as figure 1 , 2 , 3 shows: a lightweight high-speed maglev vehicle running gear device, including a main longitudinal beam unit 200 and two suspension frame units 100 connected to it.

[0041] Among them, the suspension frame unit 100 is mainly composed of the electromagnet support arm 1, the lower connecting piece of the support arm 2, the upper connecting piece 3 of the support arm, the air spring mounting beam 4, the main beam 5, the transverse stop mounting beam 6, and the transverse stop mounting seat. It is composed of 7 parts, and the parts on the suspension frame unit 100 are connected by high-strength bolts. Specifically, there are four electromagnet support arms, each of which is a set of two, each of which is connected by the upper connecting member 3 of the support arm and the lower connecting member 2 of the support arm, and then connected with the two ends of the main beam 5. An air spring 9 and a lateral stop device 300 are installed on the main beam 5....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Effective diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com