Broken cord thread wet-drawn wire identifying device

A technology of identification device and pay-off device, which is applied in auxiliary devices for rope making, textiles and papermaking, textile cables, etc., can solve the problems of wasting manpower and material resources, affecting work efficiency, and broken wires in wet pulling coils, so as to avoid production waste , Improve production efficiency, reduce the effect of improvement cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

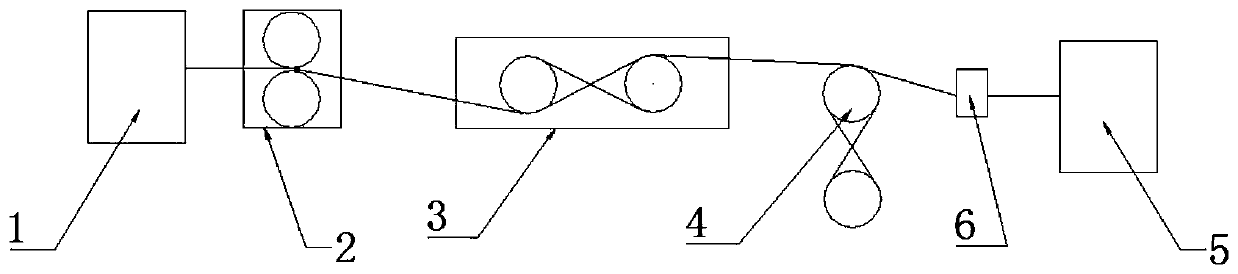

[0019] see figure 1 As shown, the present invention discloses a broken wire identification device for cord wet drawn steel wire, which includes a wire unwinding device 1, a virtual twister device 3, a traction device 4, a wire take-up device 5, and a broken wire identification and alarm device 6; A deformer device 2 is provided between the thread device 1 and the virtual twister device 3; the traction device 4 is provided at the rear end of the virtual twister device 3, and the wire take-up device 5 is provided at the rear end of the traction device 4; broken wire identification and alarm The device 6 is arranged between the pulling device 4 and the wire take-up device 5 .

[0020] The pay-off device 1 is a pay-off I-shaped wheel;

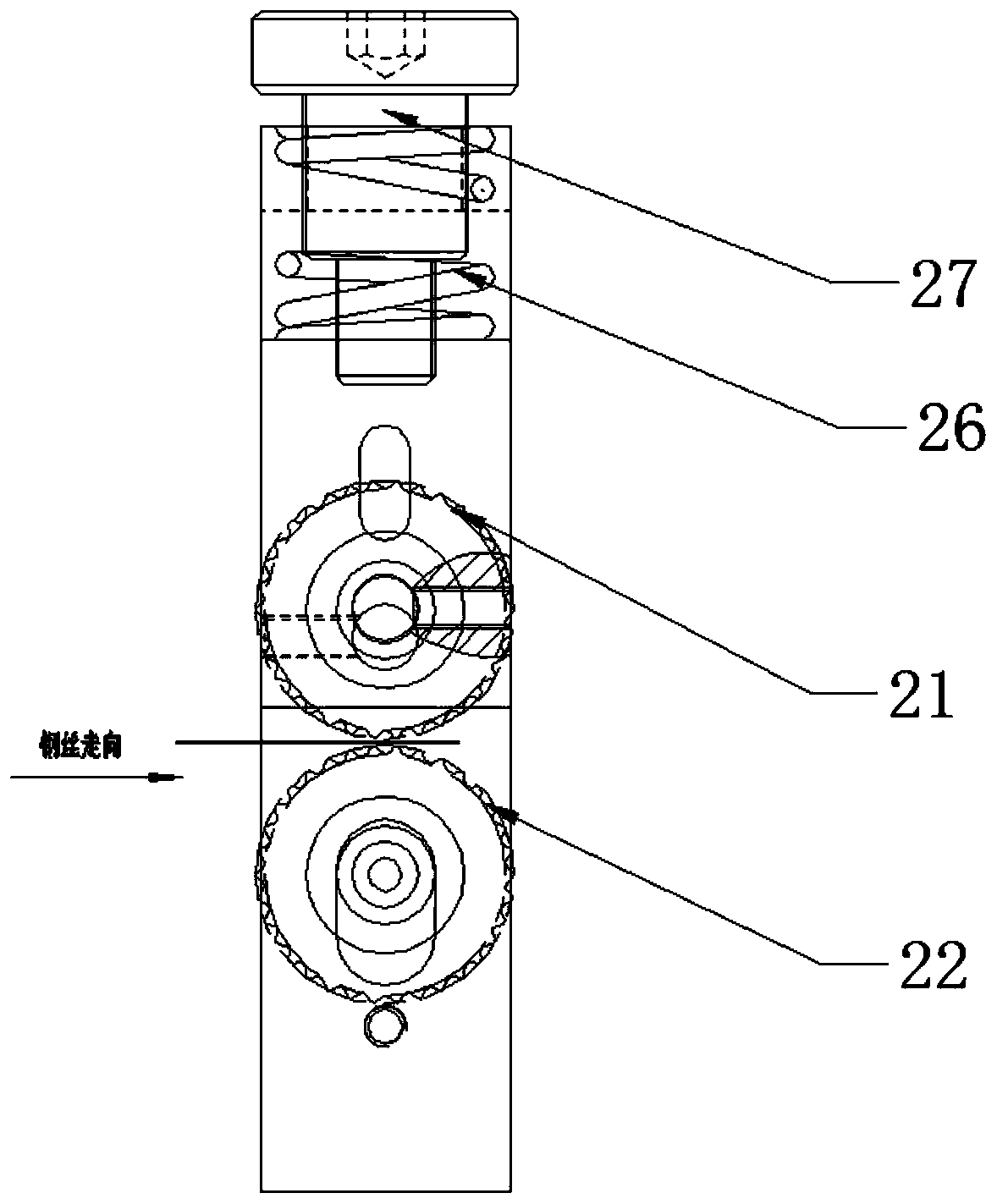

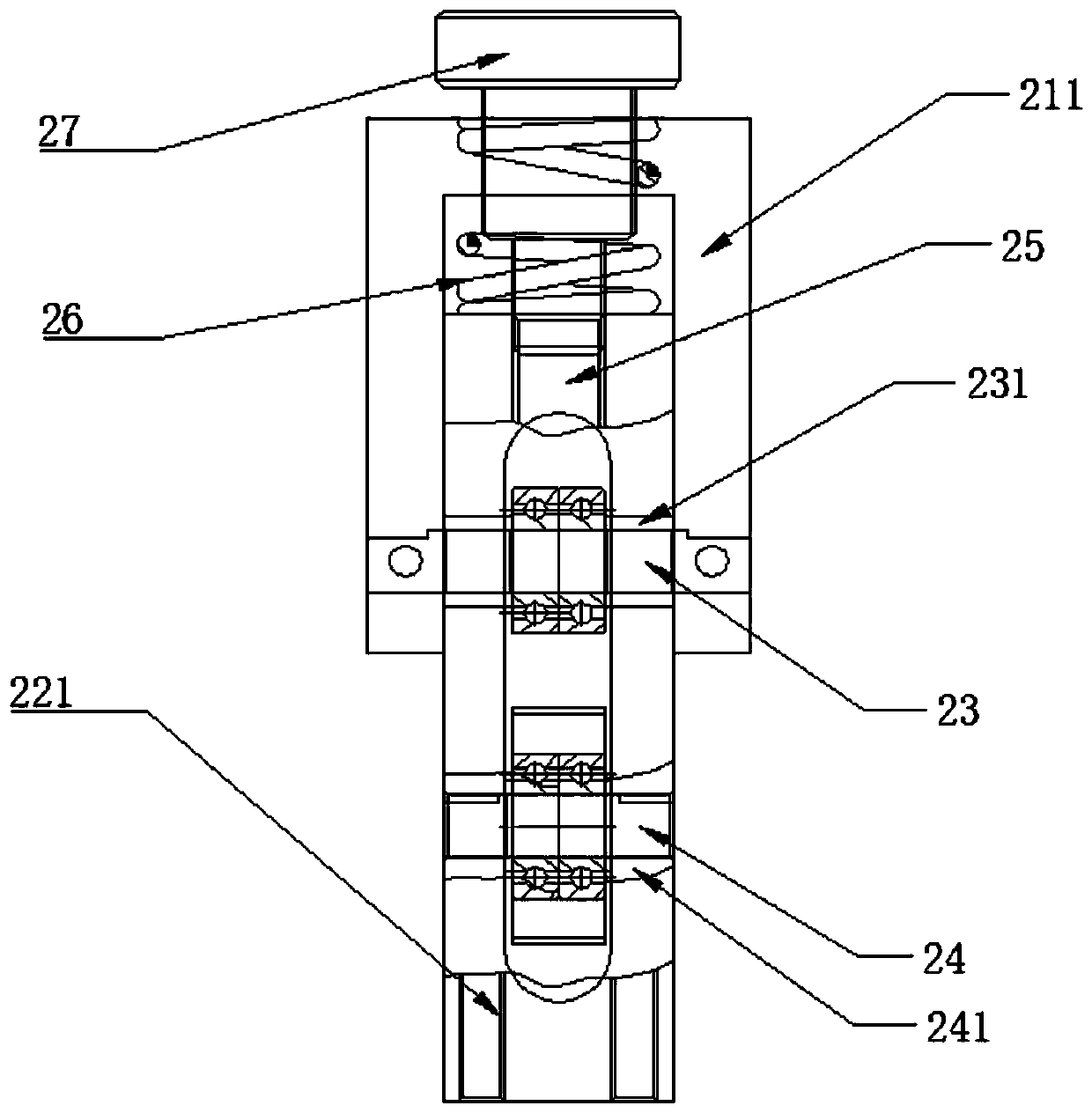

[0021] The deformer device 2 includes an upper gear 21 and a lower gear 22 that match; the steel wire passes through the middle of the upper and lower gears, the upper gear 21 is movably connected to the upper gear frame 211 by connecting the long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com