Ignition unit and low energy consumption diesel engine exhaust gas treatment system based on ignition unit

A technology for ignition unit and exhaust gas treatment, which is applied in the direction of mechanical equipment, exhaust devices, engine components, etc., can solve the problems of poisoned PGM catalyst, failure, etc., and achieve the effect of improving fuel economy, reducing sensitivity, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]The technical scheme of the present invention will be further described below in conjunction with the drawings.

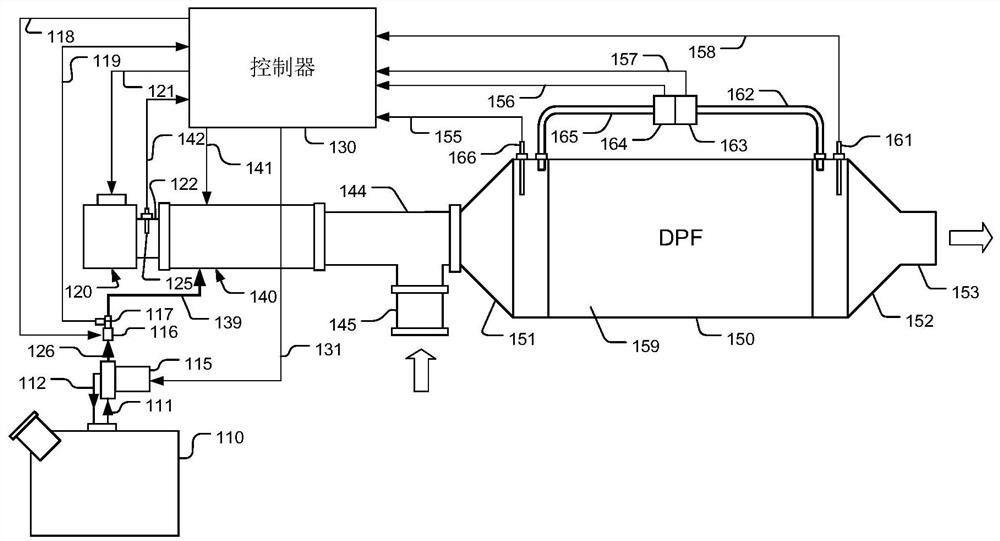

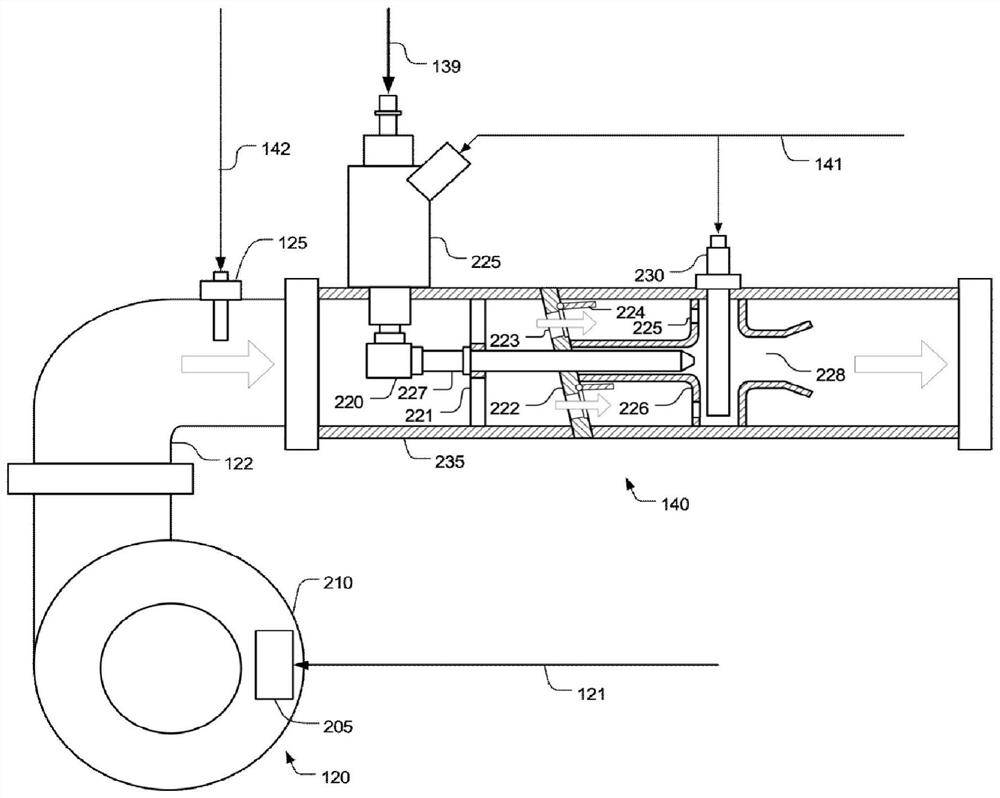

[0030]Such asfigure 1 As shown, a low energy consumption diesel engine exhaust gas treatment system of the present invention includes a controller 130, an air supply unit 120, an ignition unit 140, a three-way air passage 144, a DPF 159, a packaging unit 150, a fuel supply unit, a first temperature sensor 166, The second temperature sensor 161, the pressure sensor 163, the differential pressure sensor 164, and the mass flow sensor 125. In the present invention, the DPF 159 is wrapped in the packaging unit 150, and the packaging unit 150 is connected to the tail pipe 153 through a tapered outlet 152. On the packaging unit 150, the first temperature sensor 166 is arranged upstream of the DPF 159, and the second temperature sensor 161 is arranged downstream of the DPF 159, both of which are used to measure the temperature of the airflow passing through the DPF. The first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com