Speed reducer bonding graph model optimization method based on six-degree-of-freedom gear engagement model

An optimization method and reducer technology, applied in the direction of instruments, electrical digital data processing, geometric CAD, etc., can solve the problem that the bond graph model cannot accurately analyze the characteristics of the reducer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

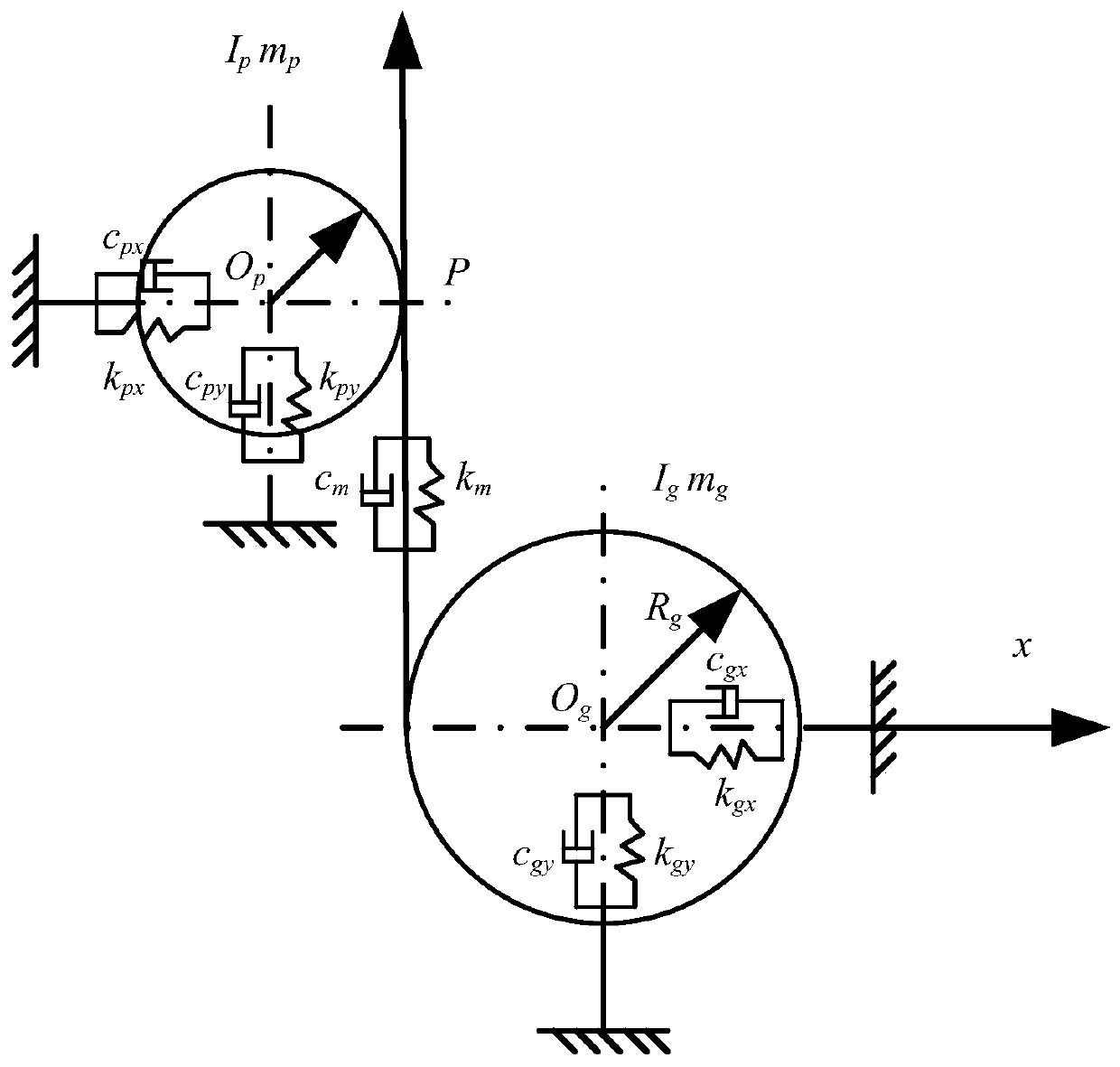

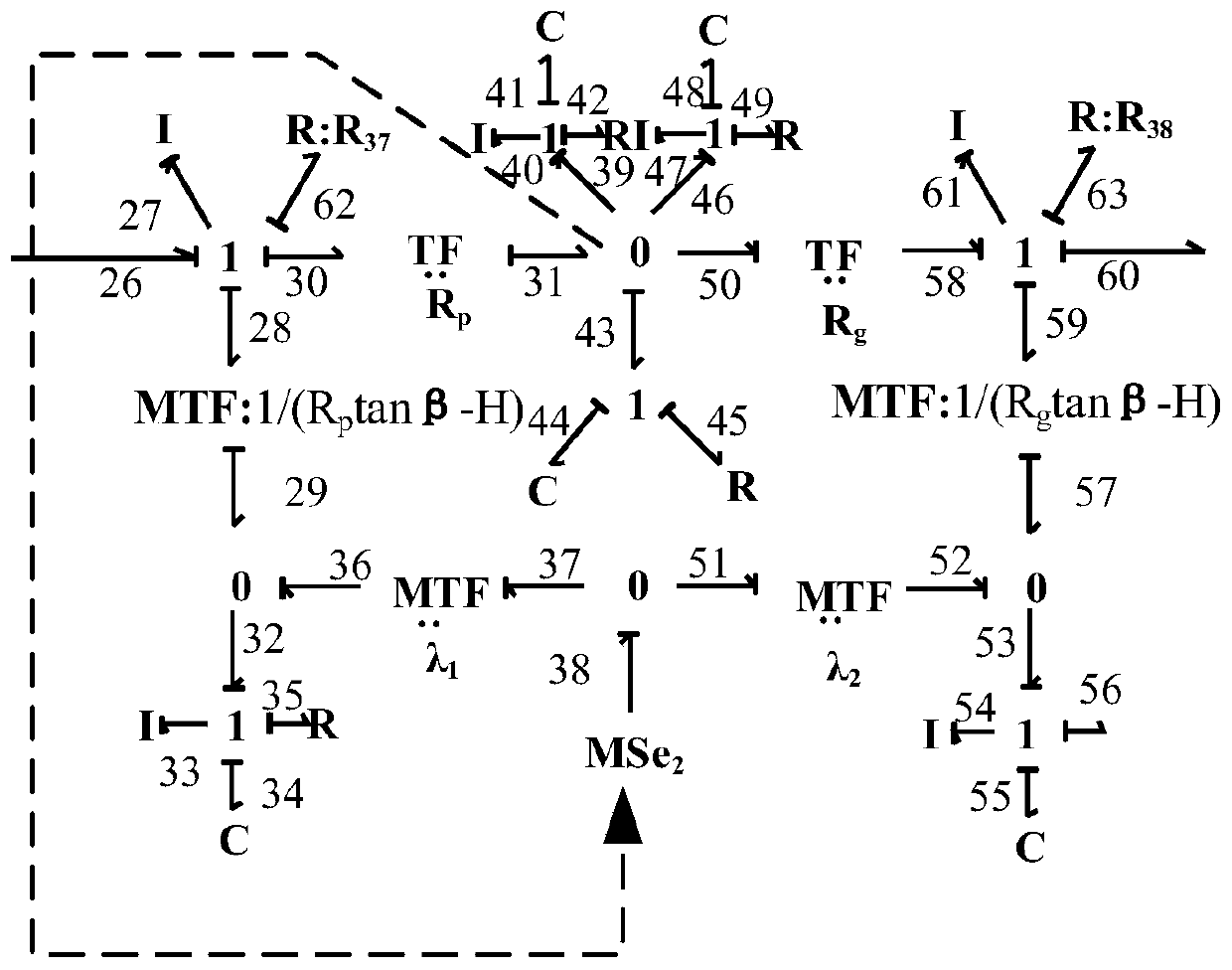

[0026] Such as figure 1 As shown, a reduction gear bond graph model optimization method based on a six-degree-of-freedom gear meshing model follows the steps below:

[0027] S1: According to the physical model of the first-stage gear pair, a six-degree-of-freedom meshing dynamics model of the first-stage gear pair is established.

[0028] See figure 1 , under the influence of tooth surface friction factors, each gear will have three degrees of freedom during the meshing process, namely the x direction, y direction and the rotation direction, so the support stiffness and The damping is equivalent to the value in the x and y direction with the combined equivalent value with k px 、k py 、k gx 、k gy and c px 、c py 、c gx 、c gy To represent, mesh stiffness and damping with the combined equivalent value k m and c m express.

[0029] S2: According to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com