Motorized spindle of machine tool

A technology for electric spindles and machine tools, which is applied in the direction of metal processing machinery parts, large fixed members, measuring/indicating equipment, etc. It can solve the problem that the glass code disc of the encoder is easily broken, the electric spindle cannot be used normally, and the stability of the encoder is reduced. problems, to achieve the effect of simplifying maintenance and replacement operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

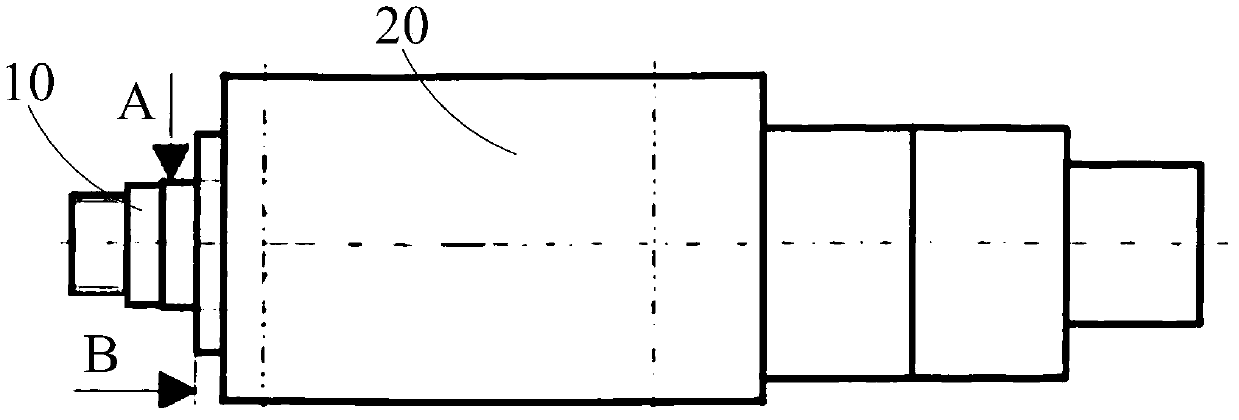

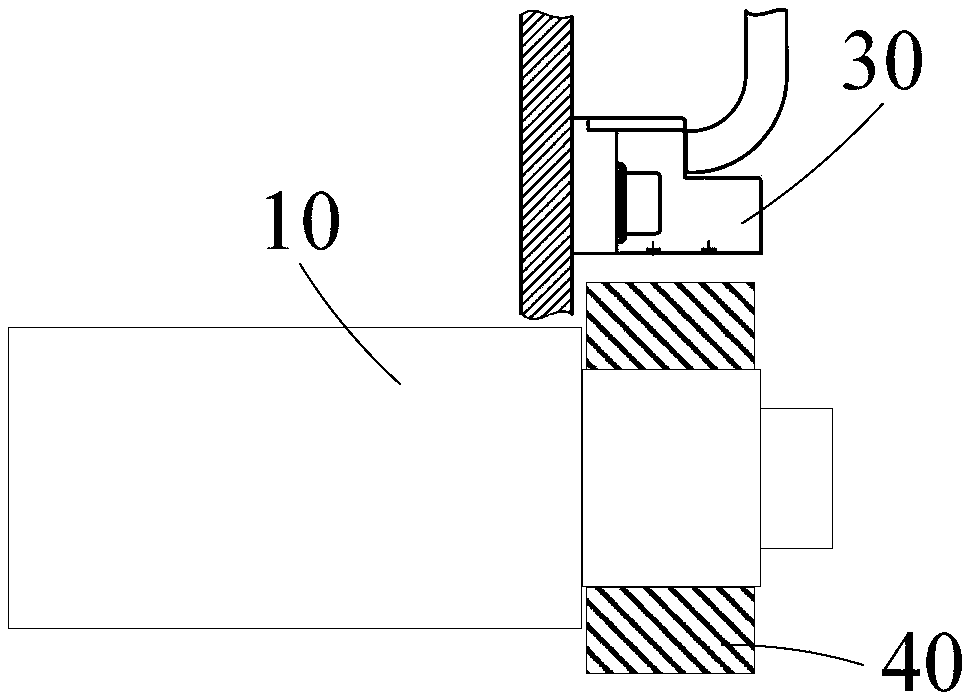

[0022] Hereinafter, embodiments of the present invention are described with reference to the drawings. The following detailed description and accompanying drawings serve to illustrate the principles of the present invention. The present invention is not limited to the described preferred embodiments, but the scope of the present invention is defined by the claims. The invention will now be described in detail with reference to exemplary embodiments, some examples of which are illustrated in the accompanying drawings. The following description is made with reference to the drawings, and the same reference numerals in different drawings represent the same or similar elements unless otherwise indicated. The aspects described in the following exemplary embodiments do not represent all aspects of the present invention. Rather, these aspects are merely examples of systems and methods of the various aspects of the invention as recited in the appended claims.

[0023] An electric sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com