Assembled wall body with built-in ceiling and floor keel connecting element

A technology of heaven and earth keels and connectors, applied in the direction of walls, building components, buildings, etc., can solve the problems of complicated installation, low structural stability, poor aesthetic performance, etc., to improve structural stability, improve aesthetic performance, and avoid handling operations. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

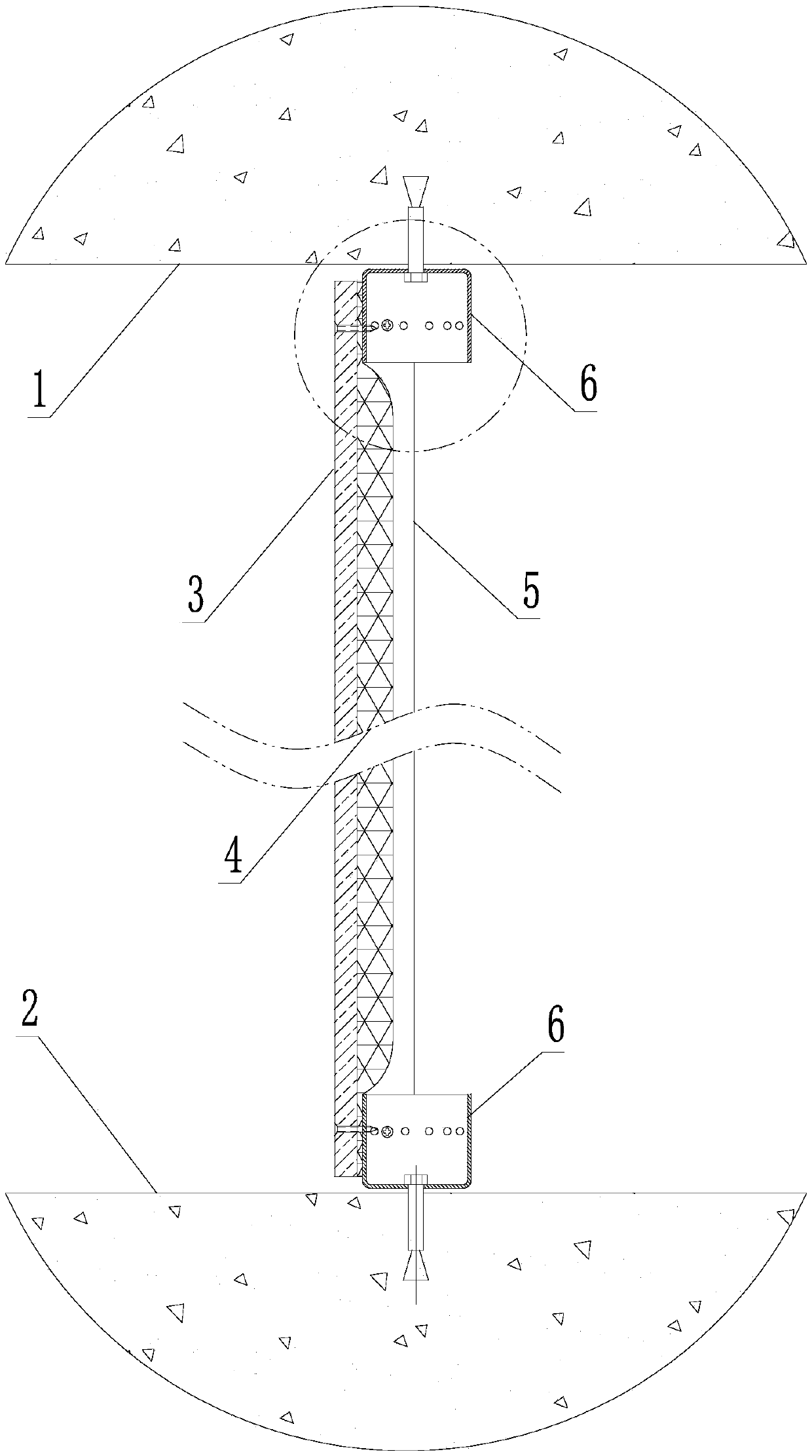

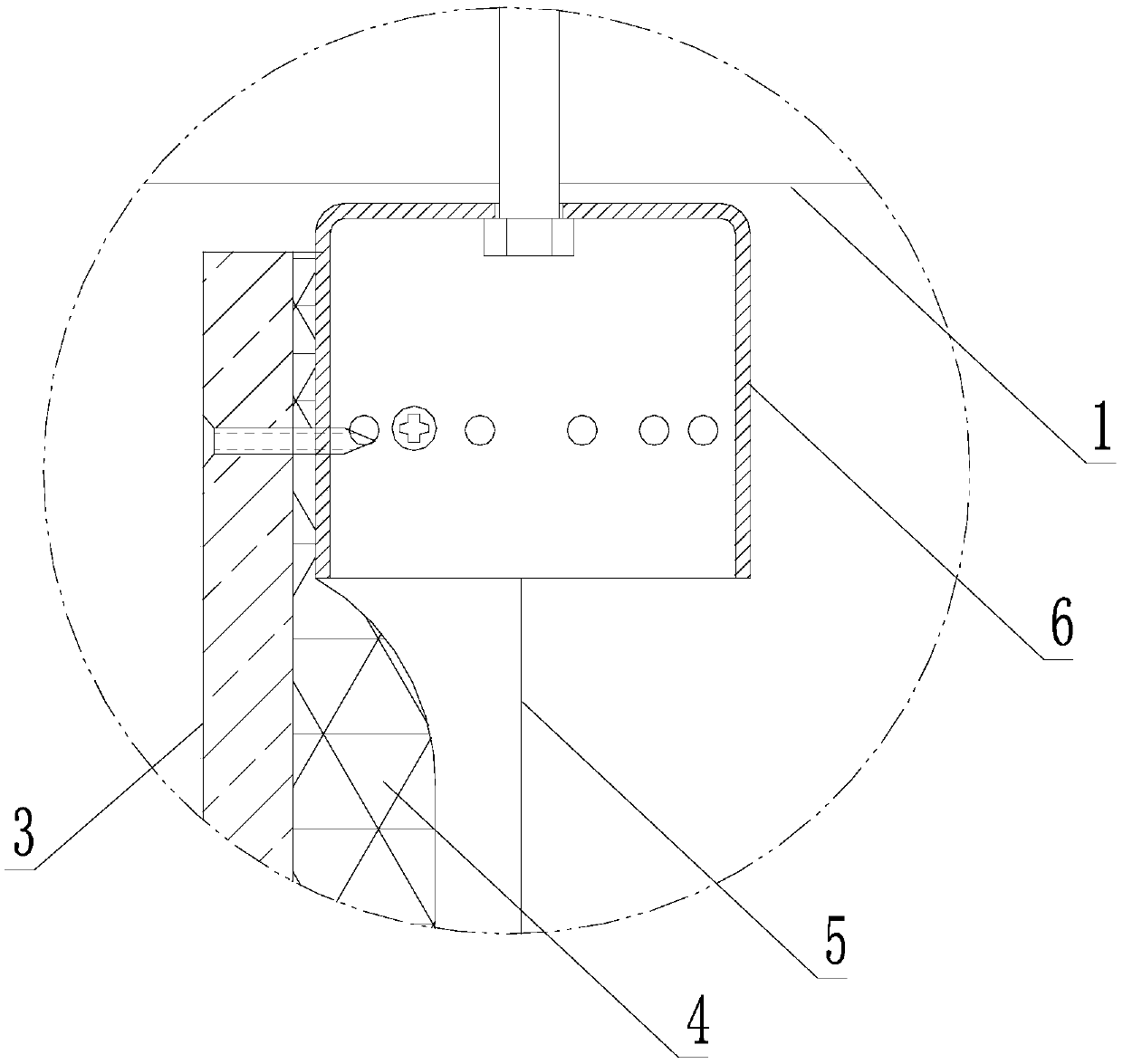

[0052] combine Figure 1 to Figure 7 As shown, Embodiment 1 of the present invention provides a prefabricated wall with built-in sky-earth keel connectors, including two opposite wall units, and an inner space between the two opposite wall units. Connector 6: through the setting of the above-mentioned built-in connector 6, the connection form of the existing external sky and earth keel can be converted into the connection form of the built-in sky and earth keel, which can effectively improve the aesthetic performance of the wall, and can also avoid subsequent external The processing operation of the heaven and earth keel.

[0053] In this embodiment, the above-mentioned wall unit includes a gypsum board 3 and a vertical keel 5, and the gypsum board 3 is fixed on the first surface of the vertical keel 5; the vertical keels 5 in the two opposite wall units are in contact with each other, and are surface contact.

[0054] In the specific operation, the surface of the vertical k...

Embodiment 2

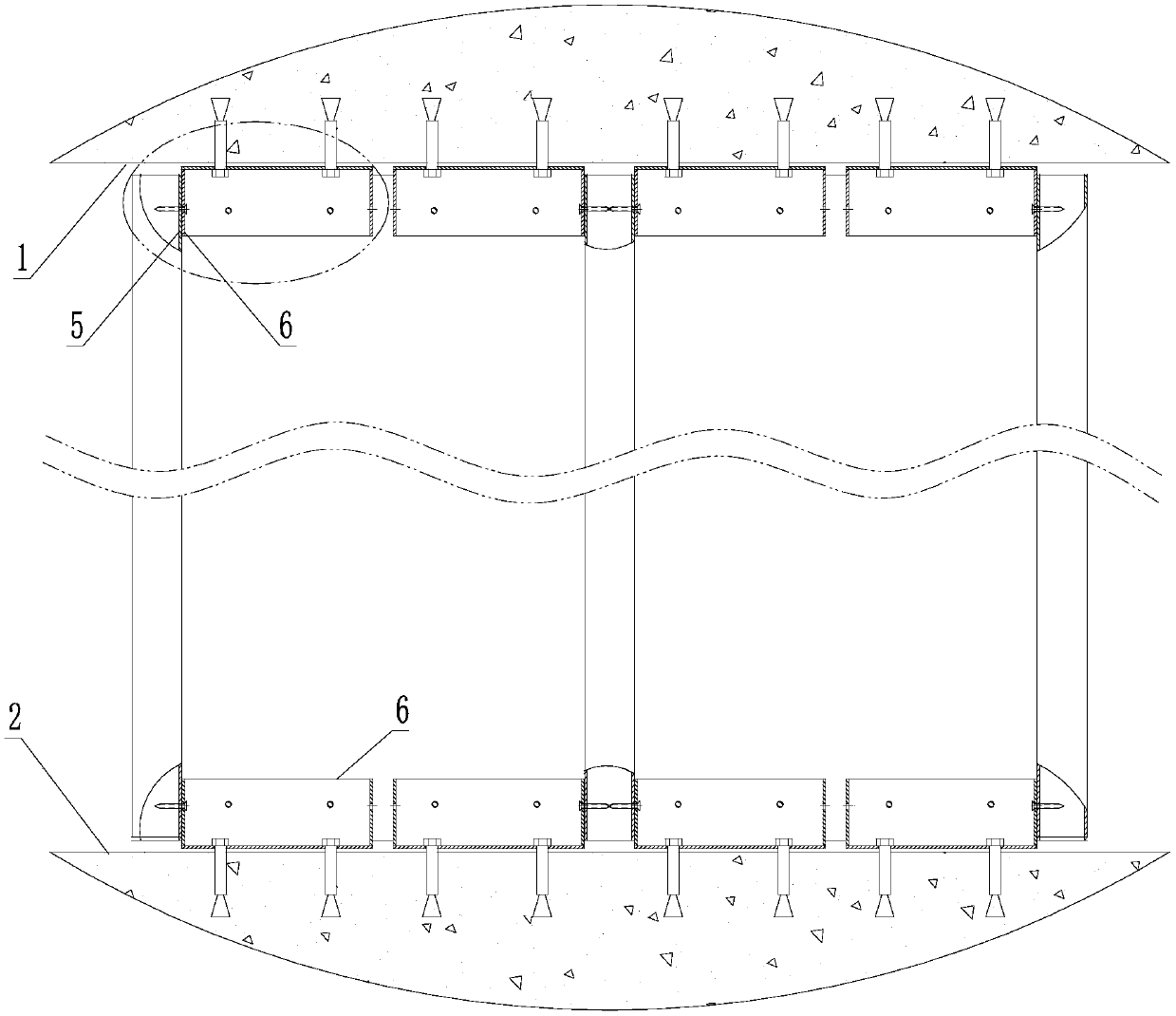

[0069] to combine Figure 9 ~ Figure 12 As shown, the second embodiment of the present invention provides a built-in space and ground keel connector, including a bottom plate 60 for connecting the roof 1 or the ground, and the bottom plate 60 is fixed on the roof 1 or the ground by expansion bolts; The first side plate 61, and the second side plate 62 for connecting the vertical keel; the first side plate 61, the second side plate 62 are vertically connected with the bottom plate 60, and the first side plate 61 and The second side panels 62 are perpendicular to each other.

[0070] The connector 6 in this embodiment is provided with two symmetrically arranged first side plates 61, and the connection structure between the bottom plate 60 and the two first side plates 61 is a U-shaped structure or a C-shaped structure; in specific operations, Through the setting of one connecting piece 6, the simultaneous connection operation of the wall units on both sides can be realized.

...

Embodiment 3

[0076] Such as Figure 13 As shown, Embodiment 3 of the present invention provides a built-in sky-earth keel connector. The main structure is similar to the connector in Embodiment 2. The bottom plate of the connector 6 is also fixed on the roof 1 or the ground by expansion bolts. Regarding the main body For the specific configuration of the structure, please refer to the detailed description in Embodiment 2, and the purpose here is to illustrate the difference between the two.

[0077] In this embodiment, the above-mentioned connector 6 is provided with a first side plate 6, and the connection structure between the bottom plate and the first side plate is an L-shaped structure; it should be noted that during the wall installation process, the setting of a connector 6, Only one wall unit can be connected; two connecting pieces 6 need to be provided to realize the connection operation of the wall units on both sides.

[0078] In the specific operation, the connector 6 is also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com