Lens lighting fixture

A lighting fixture and lens technology, which is applied in the direction of optical testing defects/defects, etc., can solve problems such as waste of electric energy, achieve the effects of saving electric energy consumption, avoiding missed inspections, and improving the accuracy rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

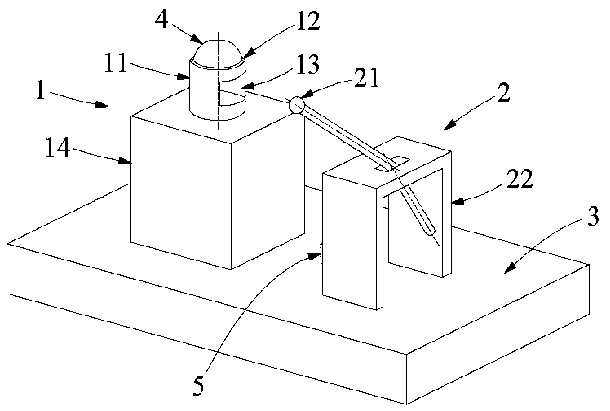

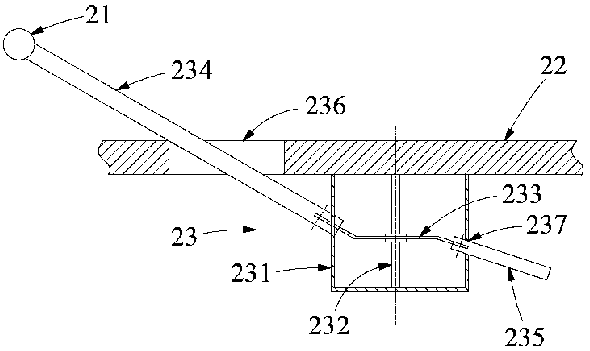

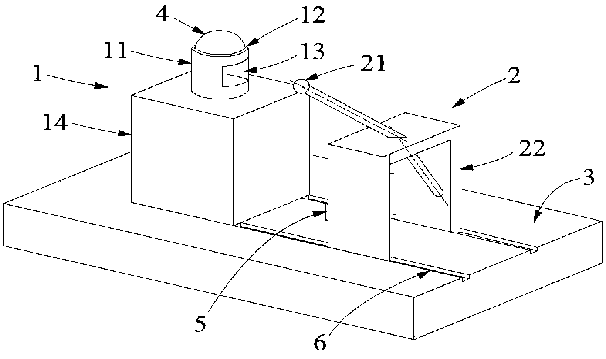

[0030] Example: refer to figure 1 As shown, the embodiment of the present application discloses a lens lighting fixture, which includes a mount 1 of the lens 4 to be inspected and a light source 2; when the light source 2 is fixed at the detection position matched with the mount 1, the light source 2 is lit ; When the light source 2 moves away from the detection position, the light source 2 is turned off. The light source 2 at least includes an LED lamp assembly, that is, in this embodiment, the lamp 21 is an LED lamp. Wherein, the detection position refers to the position of the light source 2 relative to the mounting base 1 when the light source 2 detects the lens 4 placed on the mounting base 1 .

[0031] With the above technical solution, the light source can be fixed at the detection position, or can be moved away from the detection position, and only when the light source is fixed at the detection position, the light source is clicked bright. Therefore, when the inspe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com