Method for preparing carbon membrane on surface of stainless steel bipolar plate by using graphite as carbon source

A technology of stainless steel and bipolar plates, which is applied in the manufacture of final products, fuel cell components, sustainable manufacturing/processing, etc., and can solve the problems of increased surface contact resistance of metal ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

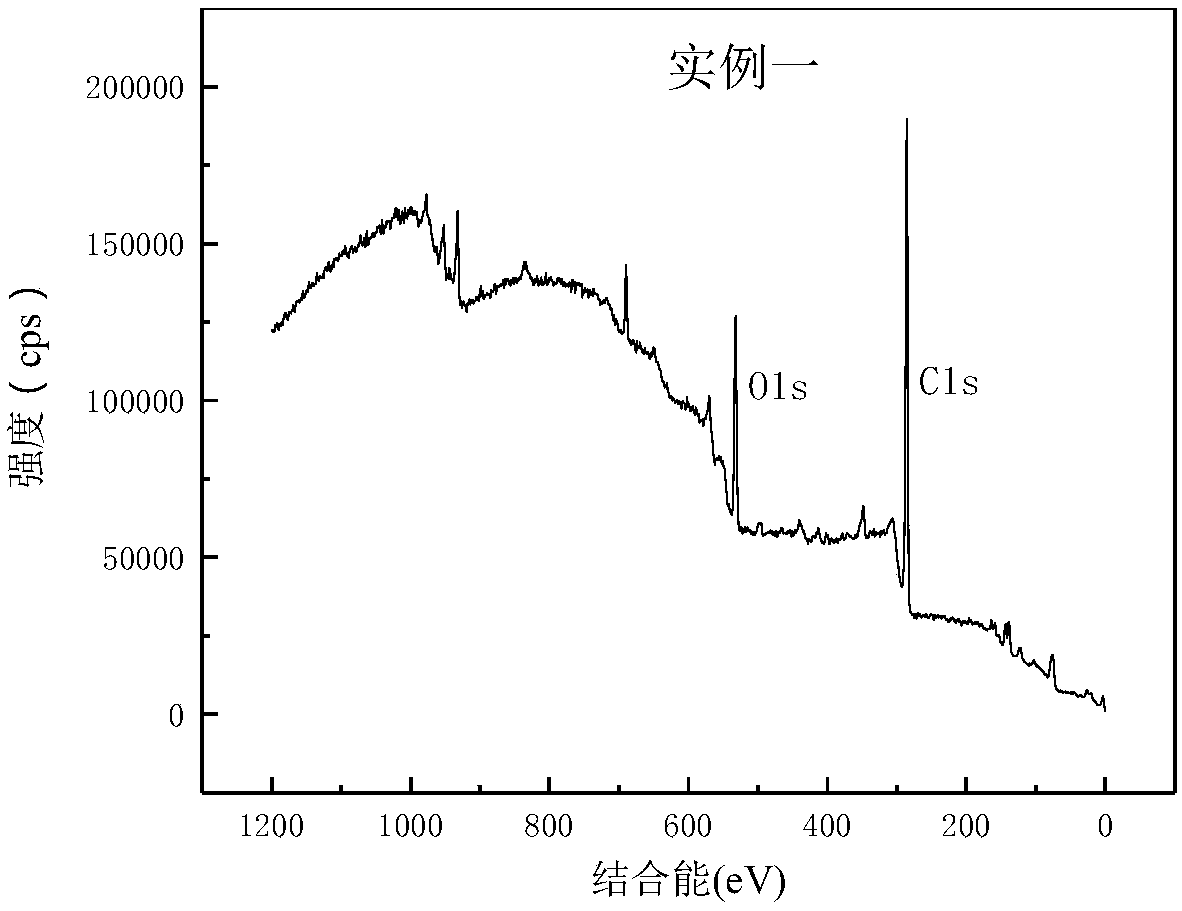

example 1

[0037] Commercial stainless steel was polished to remove the oxide film on the surface, and the grease on the surface was removed by ultrasonication in an alcohol solution for 30 minutes, and then cleaned with deionized water and dried with a hair dryer for storage.

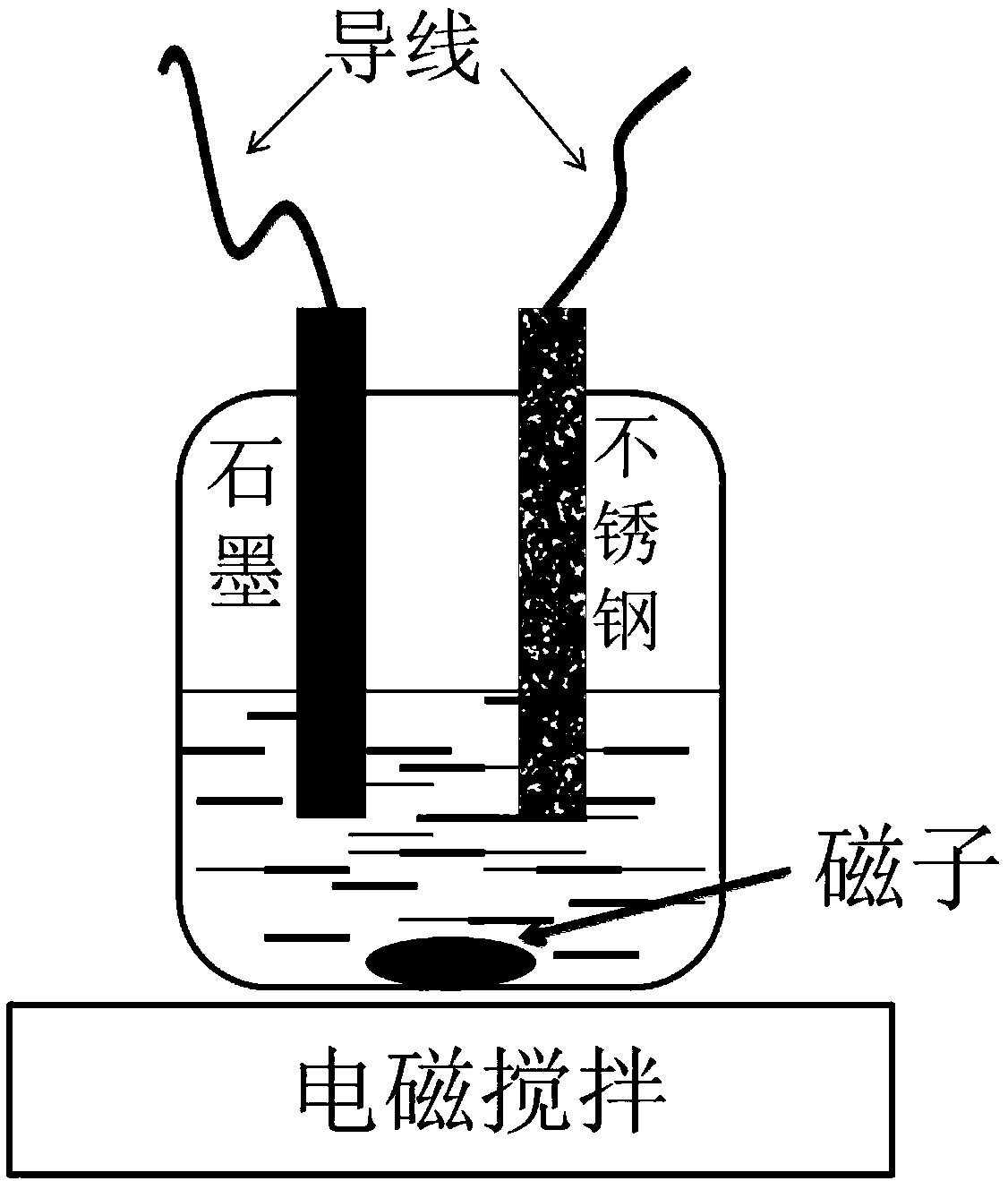

[0038] The composition of the stainless steel electrochemical deposition carbon film solution is potassium nitrate solution, the pH is adjusted to 12±0.5 with potassium hydroxide, and the concentration of potassium nitrate is 0.5M. 1 mL of methanol was added dropwise to the above solution. The solution temperature was maintained at 40±2°C. A constant current source was used as the power source for the electrochemical deposition of the carbon film, with stainless steel as the cathode and graphite rod as the anode. The above electrodes are properly connected to the power supply and immersed in the potassium nitrate solution to form the experimental device. Then choose the current density as 15mA / cm 2 The carbon ...

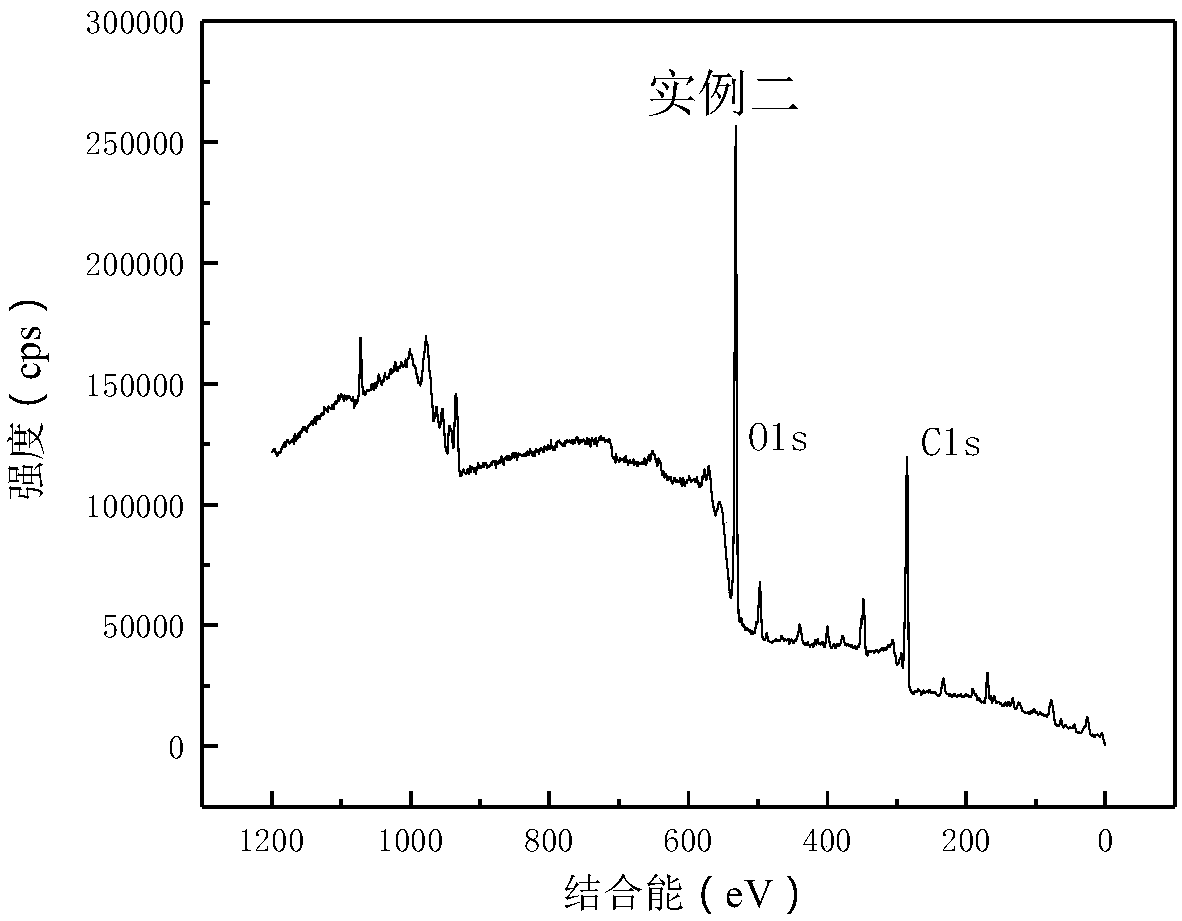

example 2

[0040] Commercial stainless steel was polished to remove the oxide film on the surface, and the grease on the surface was removed by ultrasonication in an alcohol solution for 30 minutes, and then cleaned with deionized water and dried with a hair dryer for storage.

[0041] The stainless steel electrochemical deposition carbon film solution is composed of potassium nitrate solution, the pH is adjusted to 1±0.5 with nitric acid, and the concentration of potassium nitrate is 1.0M. 5.0 mL of methanol was added dropwise into the above solution. The solution temperature was maintained at 50±2°C. A constant current source was used as the power source for the electrochemical deposition of the carbon film, with stainless steel as the cathode and graphite rod as the anode. Connect the above electrodes to the power supply correctly and immerse in the potassium nitrate solution as the experimental device. Then choose the current density as 40mA / cm 2 The carbon film is deposited, and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap