Drum washing machine

A technology for drum washing machines and washing machines, which is applied to other washing machines, washing machines with containers, washing devices, etc., and can solve the problems of complex drainage structure, unsmooth drainage, and high cost, and achieve improved control convenience, reduced production costs, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

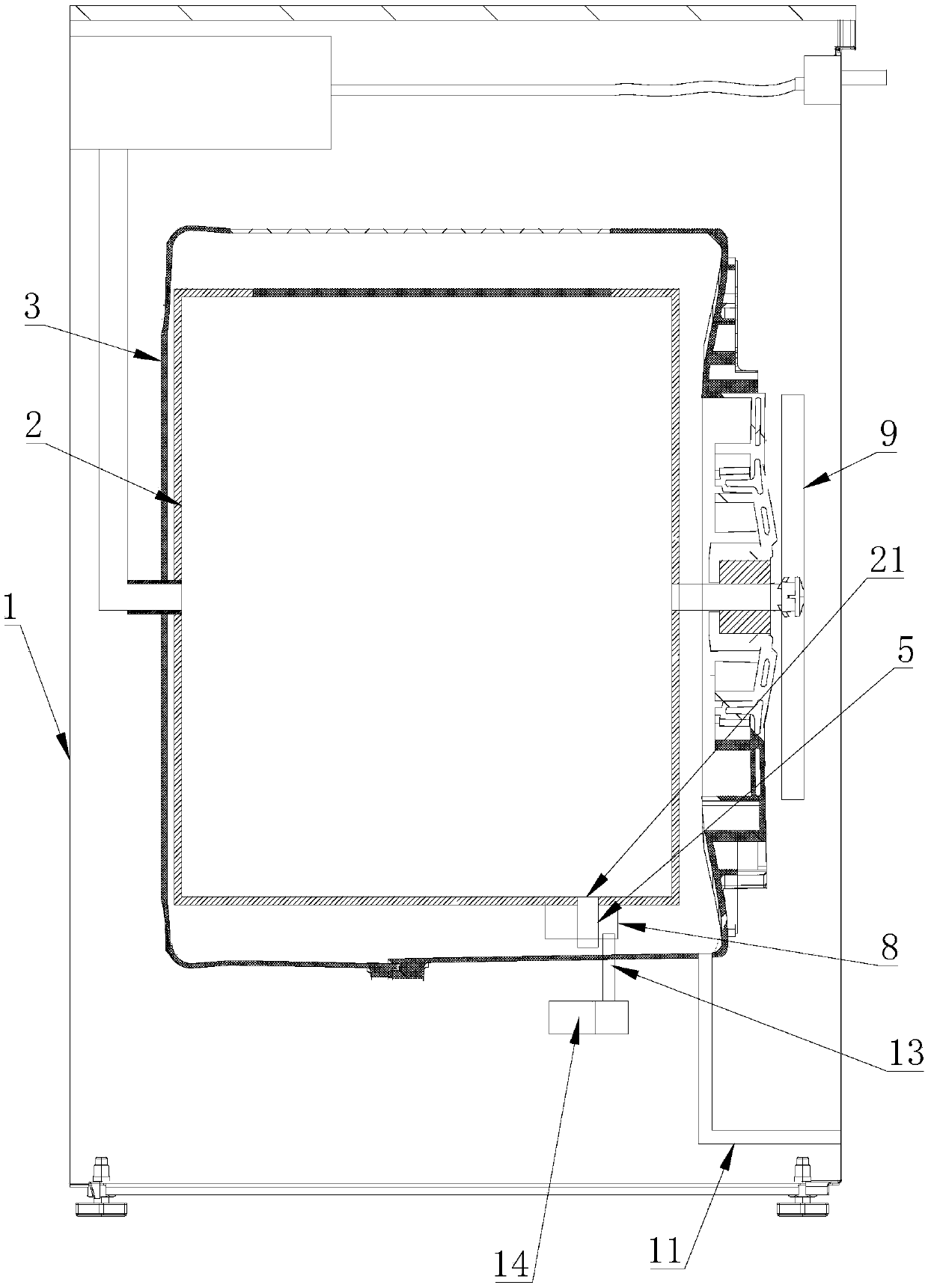

[0038] Such as Figure 1 to Figure 3 As shown, this embodiment introduces a washing machine, which includes a drum 2 installed in a casing 1, the drum 2 is a cylindrical structure with an open top and a vertical axis, the two sealed ends of the drum 2, the side The walls are not provided with dehydration holes. The two sealing ends of the drum 2 are respectively installed on the housing 1 via the rotating shaft, and the center of the sealing end at one end of the drum is connected with the driving motor 9 of the washing machine to drive the drum 2 to rotate under the action of the driving motor.

[0039] By setting the drum as a water tank with no dewatering holes and a water storage function, the technical solution of setting a hose at the drain outlet of the drum for controllable drainage can be directly set in the non-porous interior that integrates the functions of the inner bucket and the outer bucket. On the drum washing machine, the purpose of smoothly draining the was...

Embodiment 2

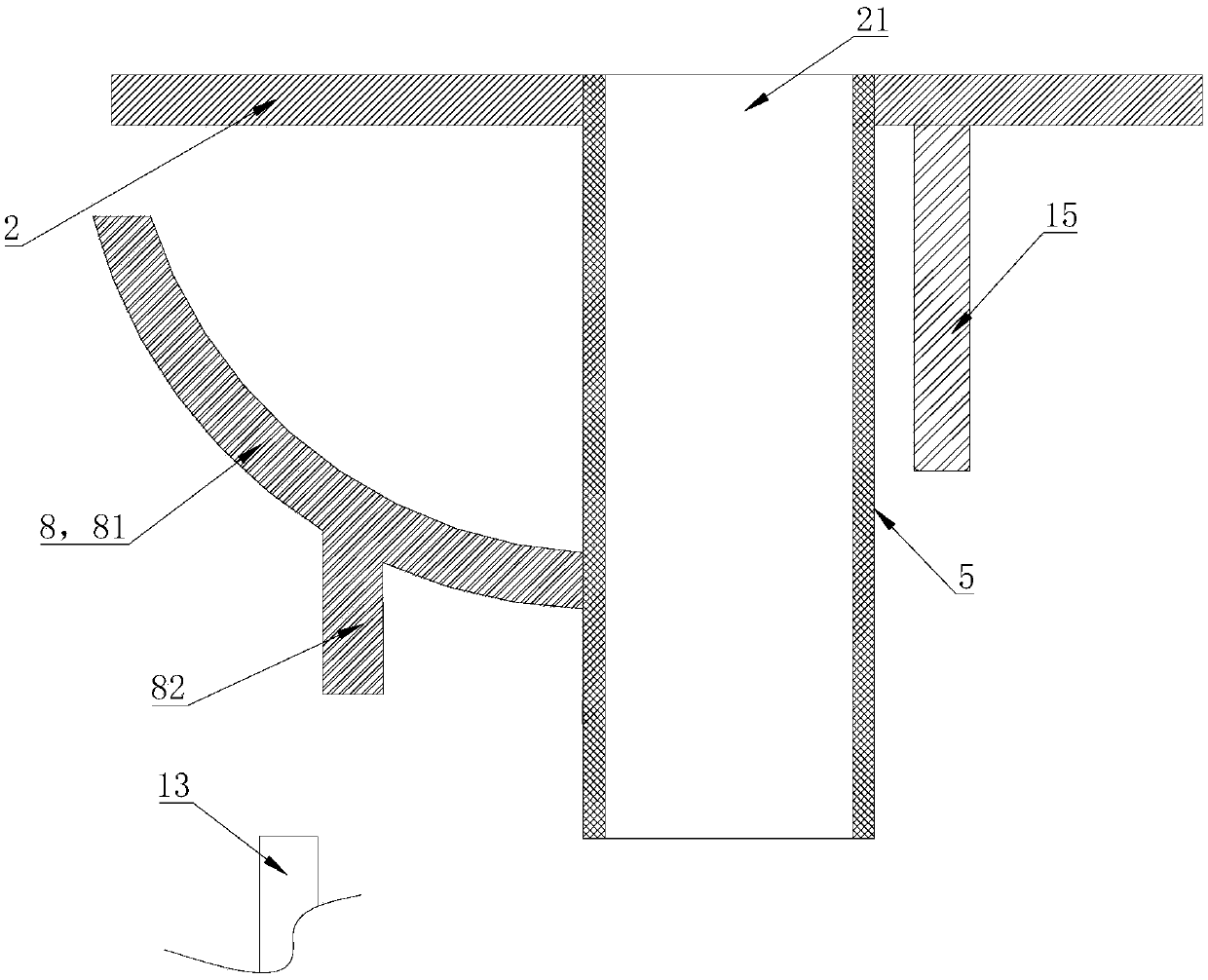

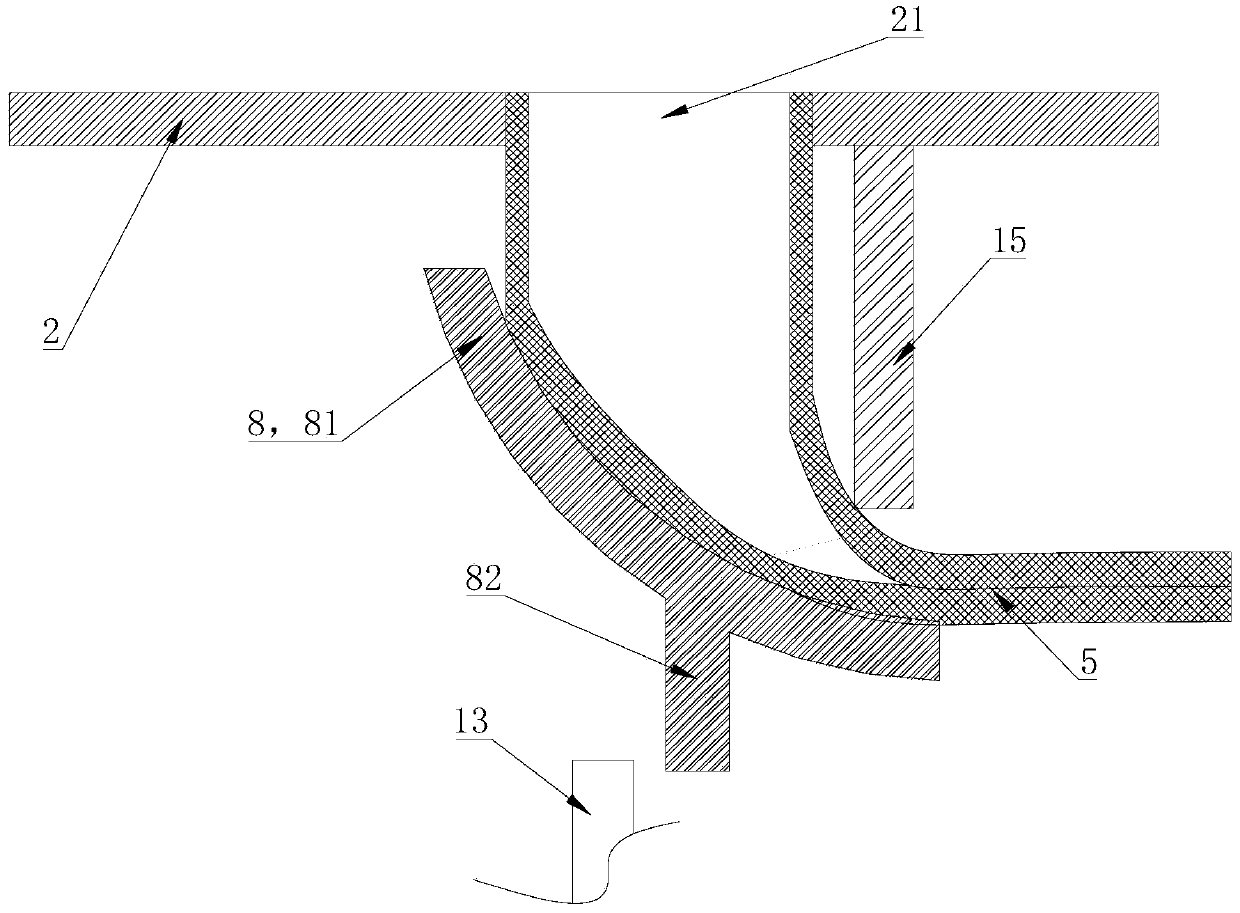

[0053] The difference between this embodiment and the above-mentioned first embodiment is that: at least one sealing end of the drum 2 is provided with a drainage port 21 at the periphery; There are slider 8. The slider 8 is arranged on one side of the hose 5 . The ejector rod constituting the driving device extends horizontally and can move telescopically in the horizontal direction, so that the extended ejector rod drives the slider 8 to push and pull along the outer side of the end of the drum 2 to approach or move away from the hose 5, thereby achieving The purpose of bending the hose controlledly and sealing the drain.

[0054] In this embodiment, a plurality of drain outlets 21 can be evenly distributed on the outer periphery of the sealing end of the drum 2, and each drain outlet 21 is respectively provided with a slider 8 on the side of the same drum rotation direction. During the rotation of the drum 2, each drain The outlets 21 are in the same movement path; the wa...

Embodiment 3

[0056] The difference between this embodiment and the above-mentioned second embodiment is that in this embodiment, in order to improve the drainage efficiency, a plurality of drain outlets 21 can be provided on the drum 2 . The side wall of the drum 2 is arranged with a plurality of drainage ports 21, and each drainage port 21 is connected with the hose 5 passing through the drum 2 respectively, and each drainage port 21 is evenly arranged on the same circumference of any section of the drum 2, so that the drum 2 During the rotation process, the movement paths of each water outlet 21 coincide, and each water outlet 21 is respectively provided with a corresponding slide block 8 towards the second circular rotation direction, so as to simultaneously close or open the soft valve at each water outlet 21 under the action of the driving device. Tube 5.

[0057] In this embodiment, a plurality of drainage outlets 21 are evenly distributed in any radial section of the side wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com