Diversion dam guiding strong-washing strong-flushing closestool

A technology for dividing dams and flushing toilets, which is applied to flushing toilets, water supply devices, sanitary equipment for toilets, etc. It can solve the problems of high water consumption, poor cleaning effect, and lagging cleaning, and solve the problem of slow-flowing rusty water , Reduce kinetic energy conduction loss, improve water-saving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

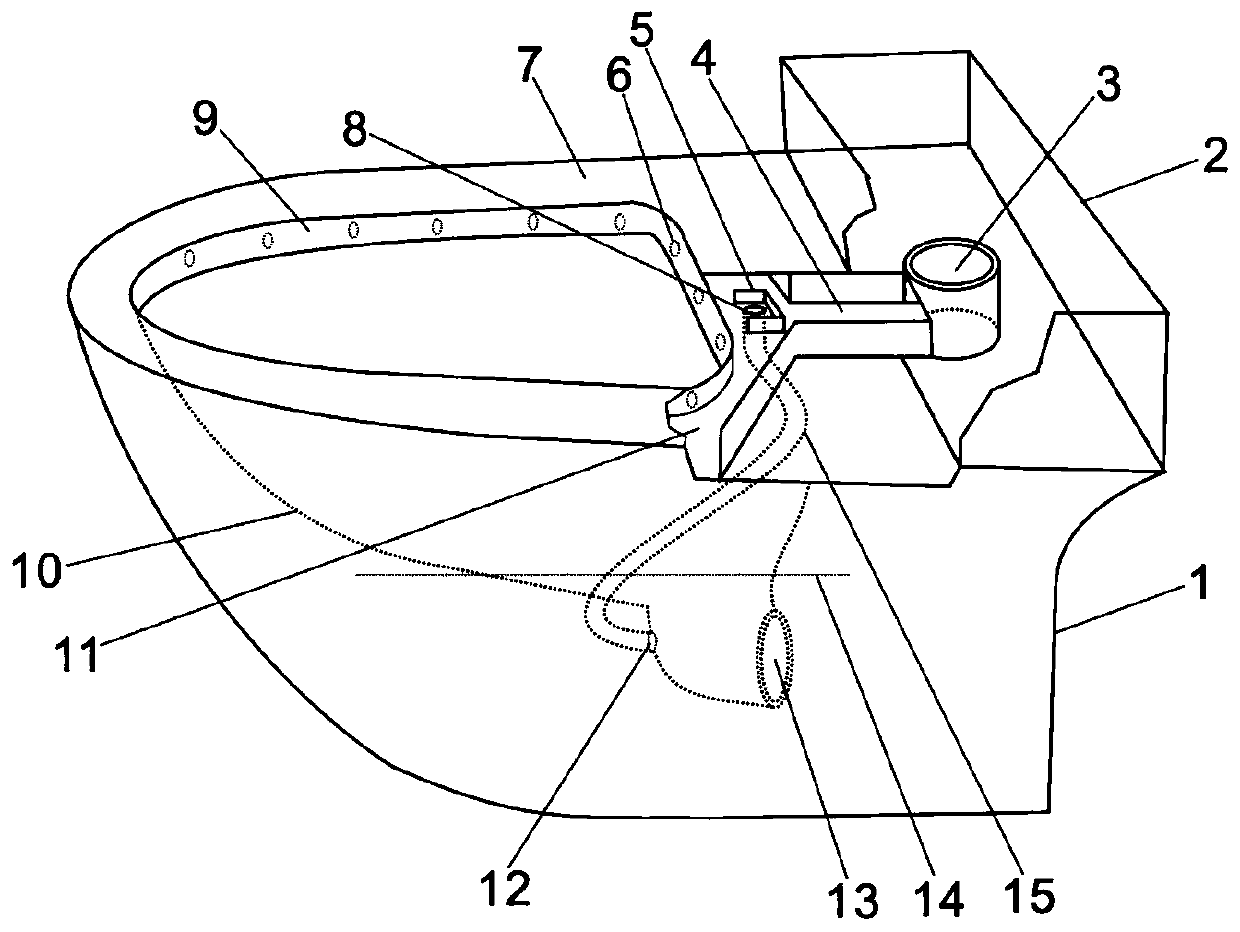

[0021] figure 1 The specific embodiment of the water diversion dam diversion strong washing strong flushing toilet of the present invention is shown. Like the traditional toilet structure, the toilet body 1 is formed with a water tank 2 and a panel 7 . Under the panel 7, a water guide ring 9, a bedpan bottom 10 and a sewage inlet 13 are sequentially formed. The direct front of sewage inlet 13 is designed with injection hole 12, and we have set water storage surface 14 above. The water outlet 3 in the water tank 2 is connected with the water guide pipe 4, and the water guide pipe 4 is connected with the water guide ring 9 and the injection water inlet 8. For ease of explanation, we are designed with water-guiding platform 11 at the lower edge of water-guiding ring 9, and water-guiding platform 11 is all communicated with water-guiding pipe 4, jet water inlet 8 and all washing holes 6. The jet water inlet 8 is designed at the junction of the water guide pipe 4 and the water g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com