Method for underground coal mine sequential mining working face hysteresis drilling drainage

A working face and sequential technology, applied in drainage, mining equipment, earthwork drilling and mining, etc., can solve problems that affect the commissioning of the working face, long construction period, and large investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

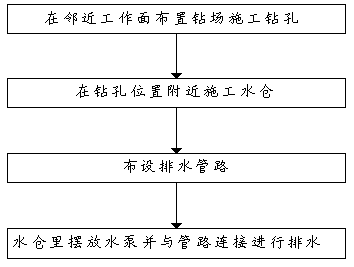

[0013] The example is a method for draining water from a lagging borehole in an underground sequential mining working face of a certain mine. The specific steps are as follows: (1) arranging the drilling site construction drilling in the adjacent working face; (2) constructing a water tank near the drilling position; (3) ) Lay out the drainage pipeline; (4) Place the water pump in the water tank and connect it with the pipeline for drainage.

[0014] The specific requirements of the step (1) are: select the place where the mining face is expected to increase the water output, arrange a drilling site, construct 7 boreholes in the drilling site, strengthen the protection of the through hole position of the mining face, and avoid mining In actual operation, methods such as erecting wooden stacks in the tunnel corresponding to the position of the through hole and hanging barbed wire at the hole are used to protect the damage caused by pressure to the borehole.

[0015] The require...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com