An integrated casing for a combined engine

An engine and casing technology, applied in the field of combined engine structure design, can solve the problems of increasing the axial size of the engine, large component size, loose structure, etc., and achieve the effects of shortening the axial size, compact structure, and low flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the accompanying drawings and embodiments.

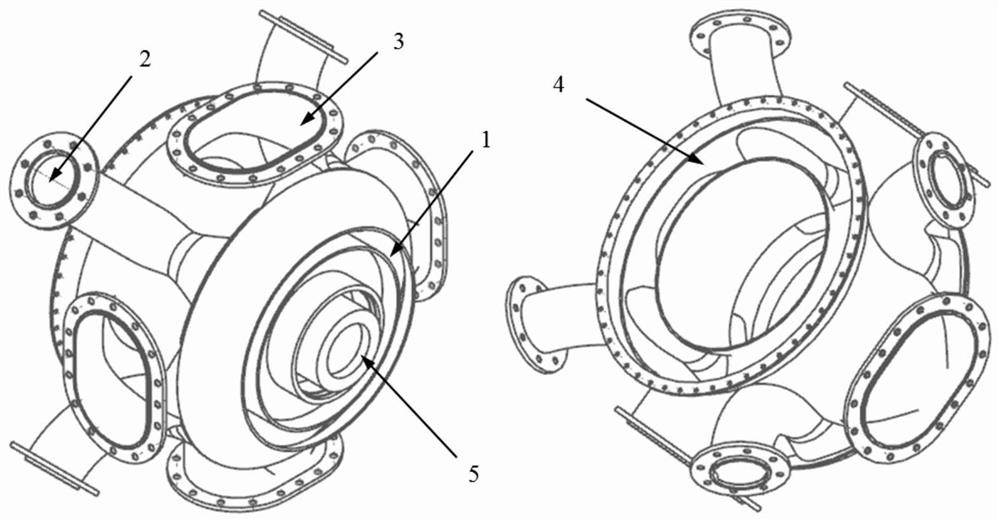

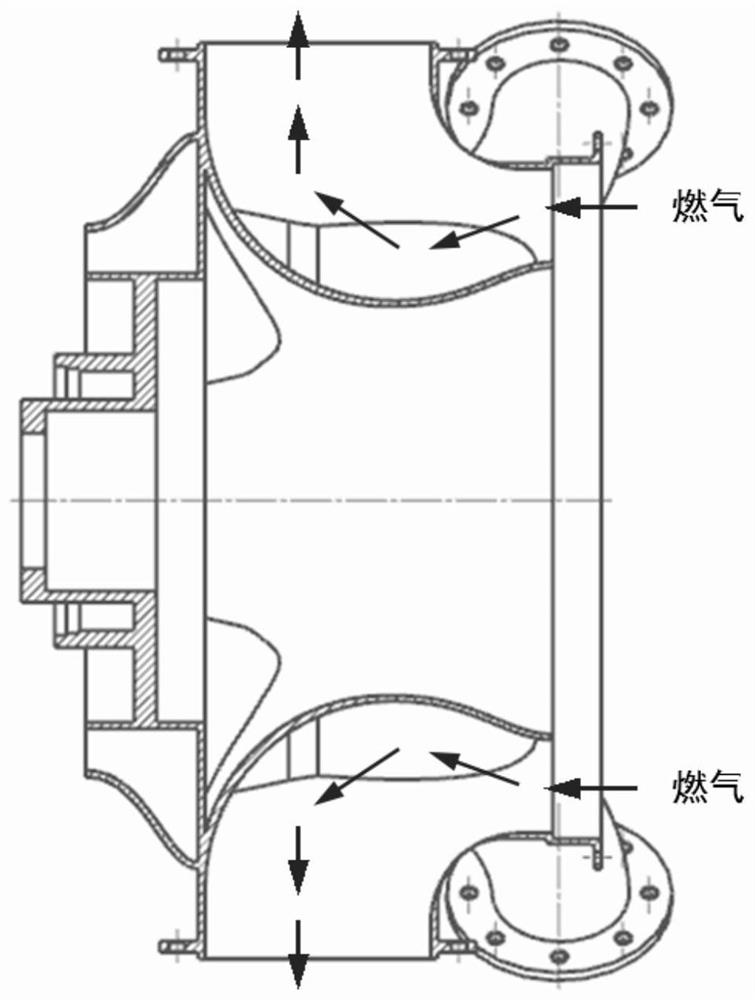

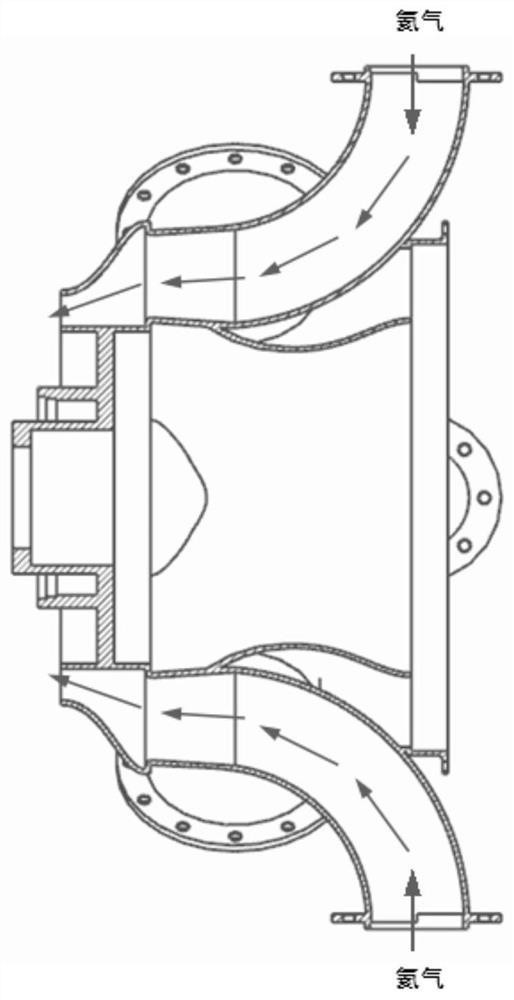

[0019] as attached figure 1 As shown, the present invention provides an integrated casing for a combined engine. The overall shape of the casing is a hollow annular cavity structure. Both ends of the annular cavity structure are respectively provided with annular air collecting chambers. They are the helium outlet 1 and the gas inlet 4 respectively. The helium outlet 1 communicates with the through-hole structure on the outer circumferential surface of the annular cavity structure, that is, the helium inlet 2, and the gas inlet 4 communicates with the through hole on the outer circumferential surface of the annular cavity structure. The structure is that the gas outlet 3 communicates with each other; a bearing seat 5 is provided at the center position of one side of the helium gas outlet 1 of the casing.

[0020] The gas inlet 4 is connected to the cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com