High-precision binocular vision measurement system and method for closure pipe

A binocular vision measurement and high-precision technology, applied in the field of closing pipes, can solve the problems of low precision, incorrect position of the bolt holes of the closing pipe flange, frequent accidents, etc., and achieve high accessibility and high-precision measurement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

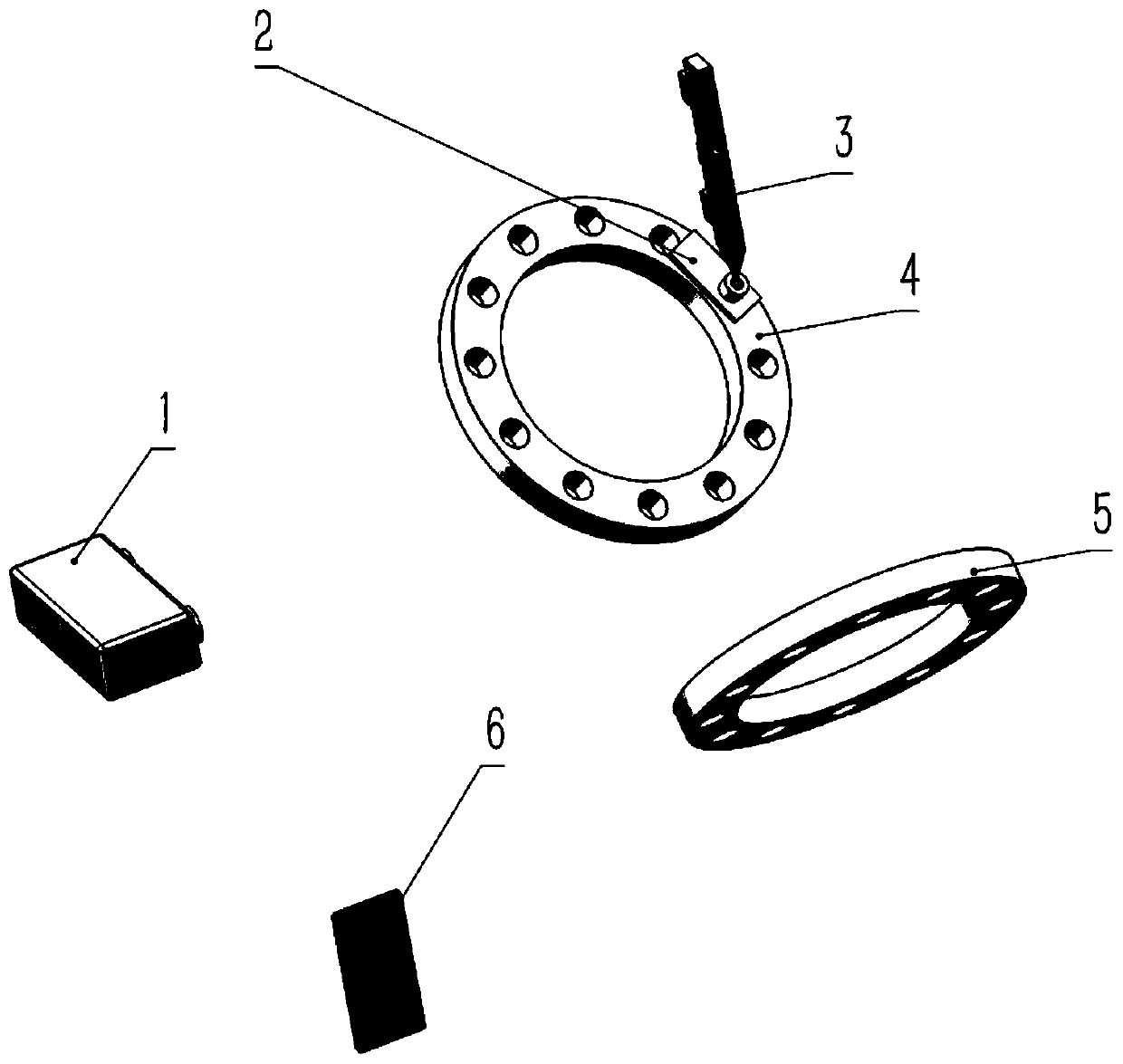

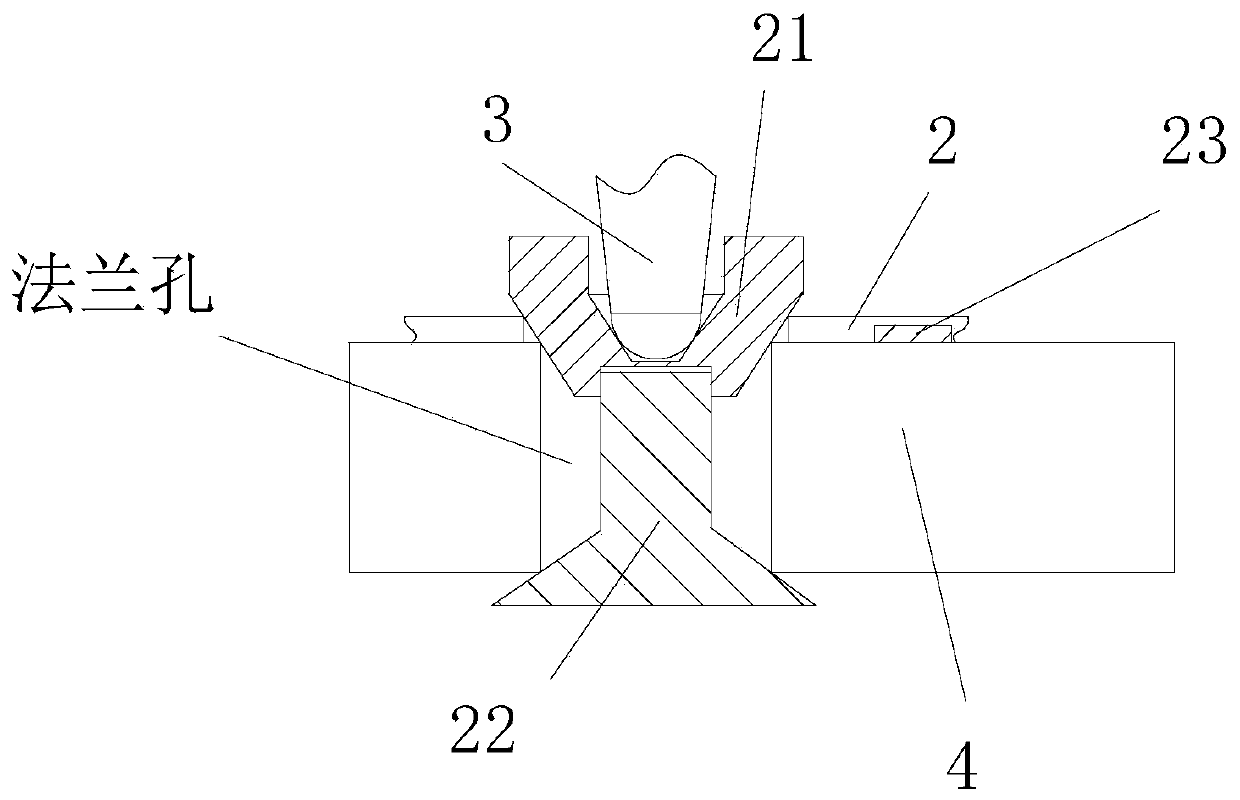

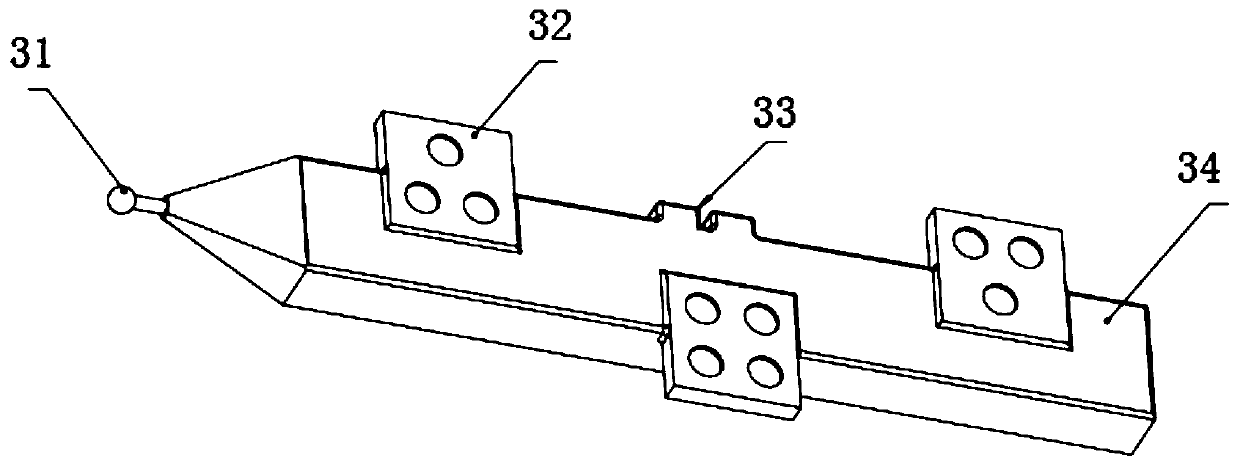

[0023] Such as Figure 1 to Figure 3 As shown, the high-precision binocular vision measurement system for closing tubes of the present invention includes a binocular high-precision three-dimensional measurement system 1, a coaxial device 2 and a target 3, and the coaxial device 2 is installed on a flange of a flange 4 4 holes, the target 3 is inserted into the coaxial device 2; the coaxial device 2 includes a mounting plate, a countersunk screw 22 and a truncated cone 21, and the countersunk screw 22 and the truncated cone 21 are installed on the mounting plate respectively. Both sides, be provided with coaxial conical hole on conical frustum 21, conical frustum 21 and countersunk head screw 22 are coaxially arranged, and mounting plate is positioned at the surface of countersunk head screw 22 side and is equipped with industrial strong magnetism 23; Target 3 comprise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com