Automatic constant-temperature device for dry battery glue sealing

A constant temperature device, dry battery technology, applied in the direction of using electric means for temperature control, device for coating liquid on the surface, auxiliary controller with auxiliary heating device, etc. Good, glue is susceptible to cold solidification and other problems, to achieve the effect of increasing the heating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

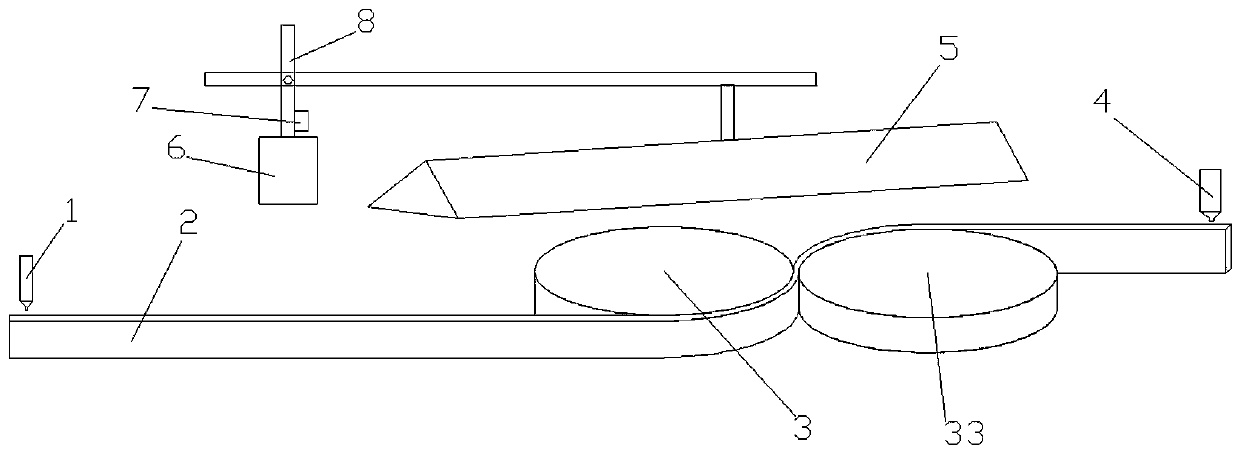

[0012] Such as figure 1 As shown, an automatic constant temperature device for dry battery sealing, including a glue application device 1, a capping device 4, a heating device 5, a motor 6, a support rod 8, a temperature sensor 7, a transmission belt 2 and a guide roller 3, and a transmission belt 2 Pass through the middle of two adjacent guide rollers 3, the gluing device 1 is installed above the left end of the conveyor belt 2, the capping device 4 is installed above the right end of the conveyor belt 2, and the heating device 5 is installed between the two guide rollers 3 Above, the heating device 5 is connected with the motor 6 through the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com