Device for dynamically controlling gas flow mode and wafer processing method and equipment

A dynamic control and gas technology, applied in semiconductor/solid-state device manufacturing, electrical components, discharge tubes, etc., can solve the problem that wafer etching cannot achieve better etching uniformity, and meet the needs of precise control and high productivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

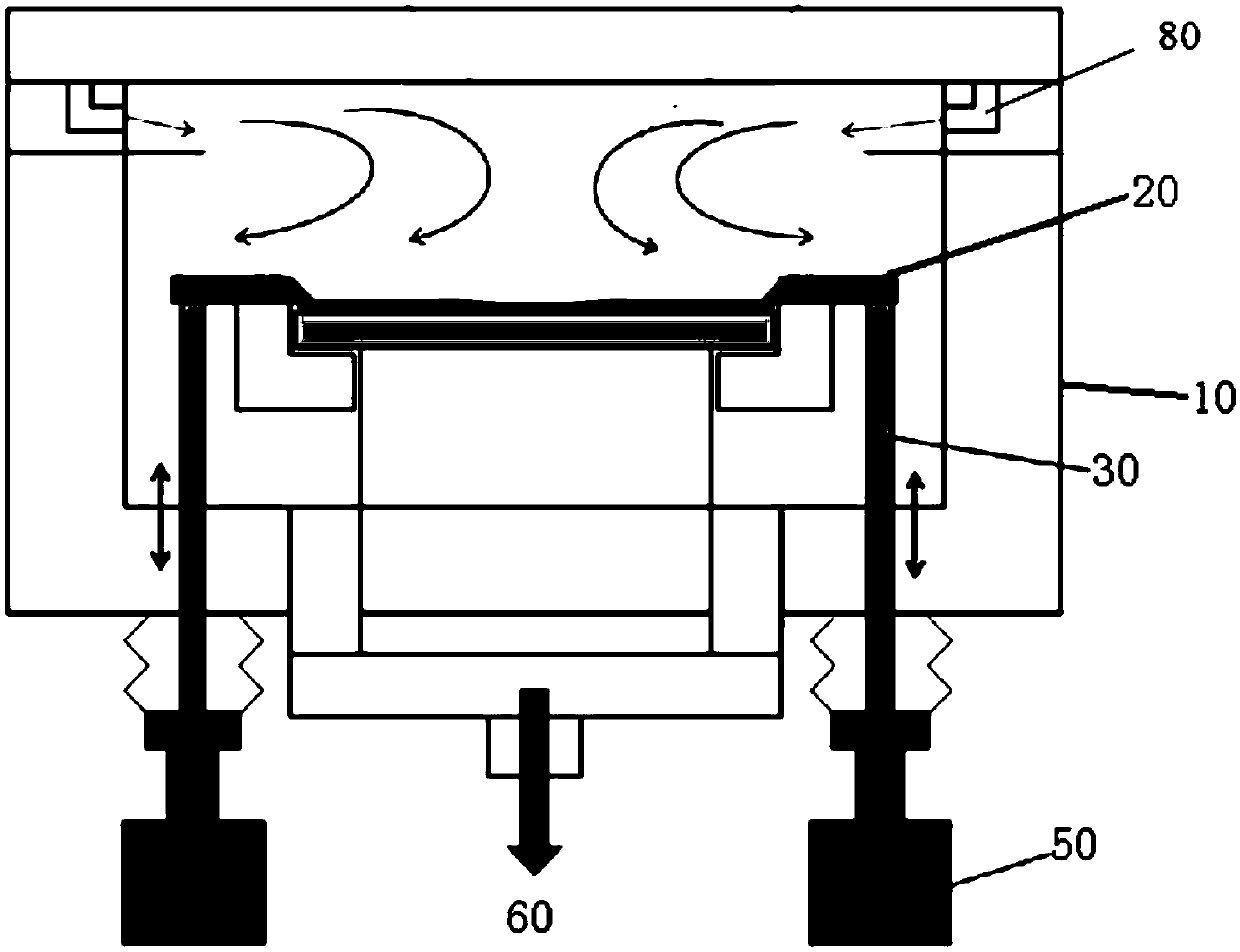

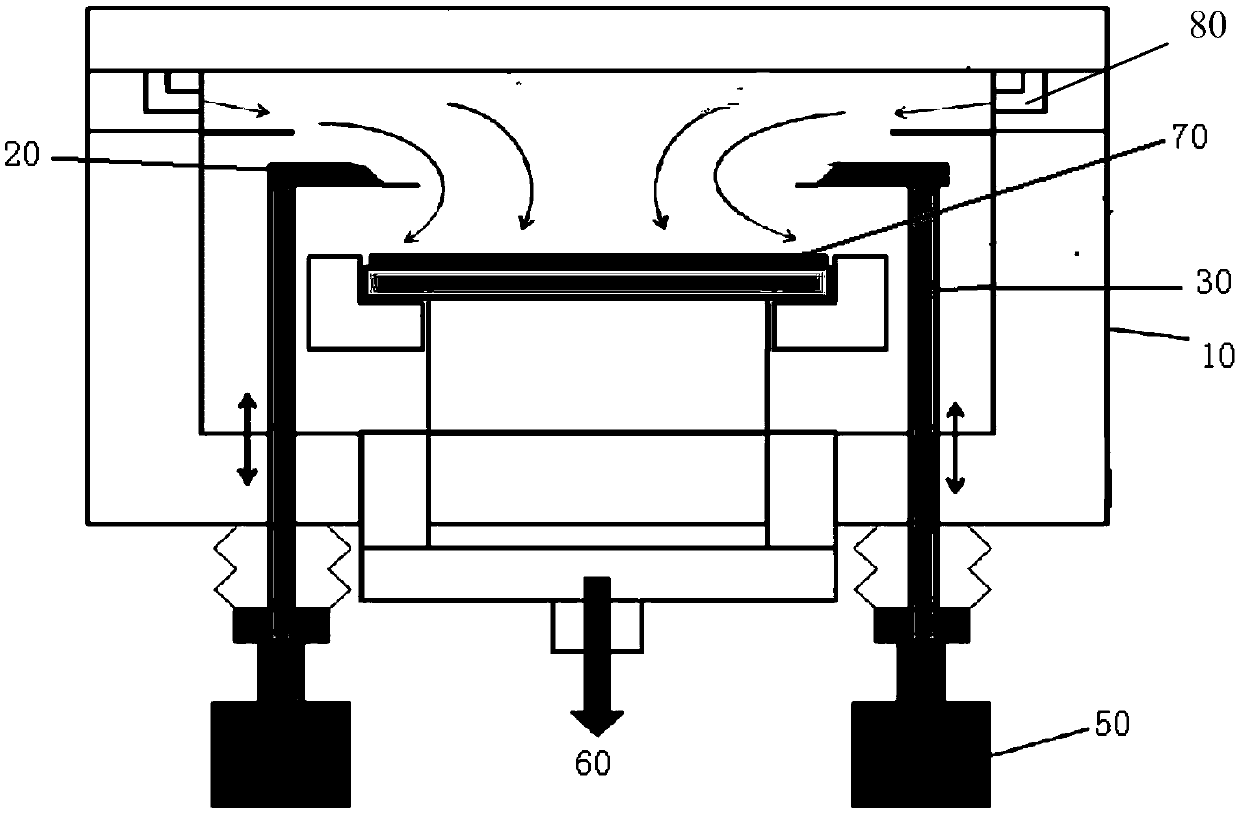

[0025] The invention provides a device to adjust the chemical form in the processing chamber by changing the gas flow pattern in the processing chamber; Adjustment of wafer etching effect. The invention also provides a wafer processing method and wafer processing equipment using the device.

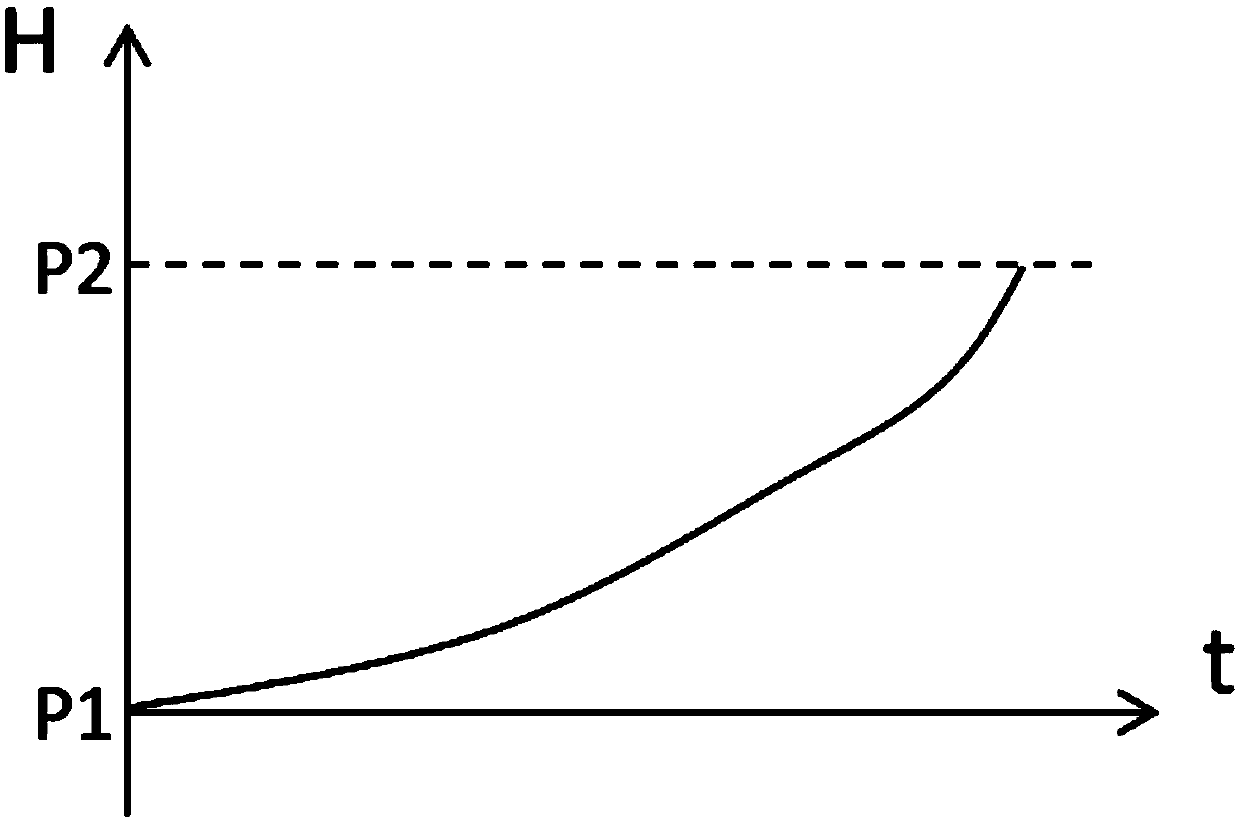

[0026] The invention provides a gas shielding ring whose height can be adjusted dynamically, which can change the gas flow pattern of the gas from the gas inlet to the vicinity of the surface area of the wafer. In order to meet the requirements of the same or different processes, the adjustment of the height of the gas shielding ring in the present invention can be completed in the processing chamber with gas pressure, without opening the processing chamber during the process.

[0027] Such as figure 1 As shown, the gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com