Intelligent leakage detection robot and detection method for detecting leakage point of liquid filling pipeline

A pipeline leak point and robot technology, applied in pipeline systems, special pipes, pipe components, etc., can solve the problems of missed judgments and misjudgments, and the inability of real-time transmission of image data in pipes to facilitate discovery and positioning, and data processing difficulties. Low, simple hardware effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

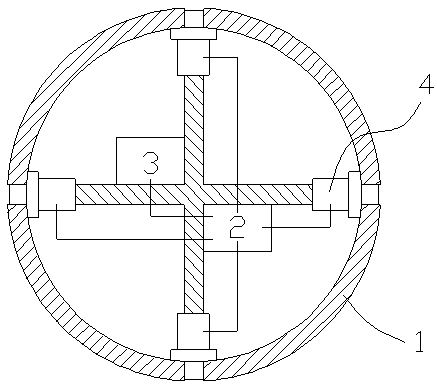

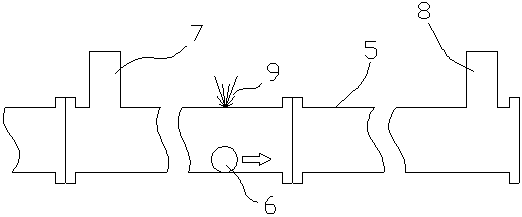

[0034] An intelligent leak detection robot for detecting leaks in liquid-filled pipelines, the innovation of which is: the intelligent leak detection robot includes a housing 1, a control module 2 and a sensing device; the sensing device is selected from the following three schemes: Choose one:

[0035] Option 1: the sensing device uses a magnetic field sensor 3; Option 2: the sensing device uses a plurality of pressure sensors 4; Option 3: the sensing device uses a magnetic field sensor 3 and a plurality of pressure sensors 4 at the same time;

[0036] When the sensing device adopts the first scheme, the structure of the intelligent leak detection robot is as follows: the control module 2 and the magnetic field sensor 3 are installed in the inner cavity of the housing 1 through a bracket, and the housing 1 wraps the control module 2 and the magnetic field sensor 3 completely. Sealing, the control module 2 and the magnetic field sensor 3 are electrically connected;

[0037] W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com