Batch type automatic egg taking-out device capable of preventing eggs from being damaged

A take-out device and batch-type technology, which is applied in the field of laying hen breeding, can solve problems such as stained with dirt, easy to attract mosquitoes, and environmental impact on the farm, and achieve the effect of helping to preserve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

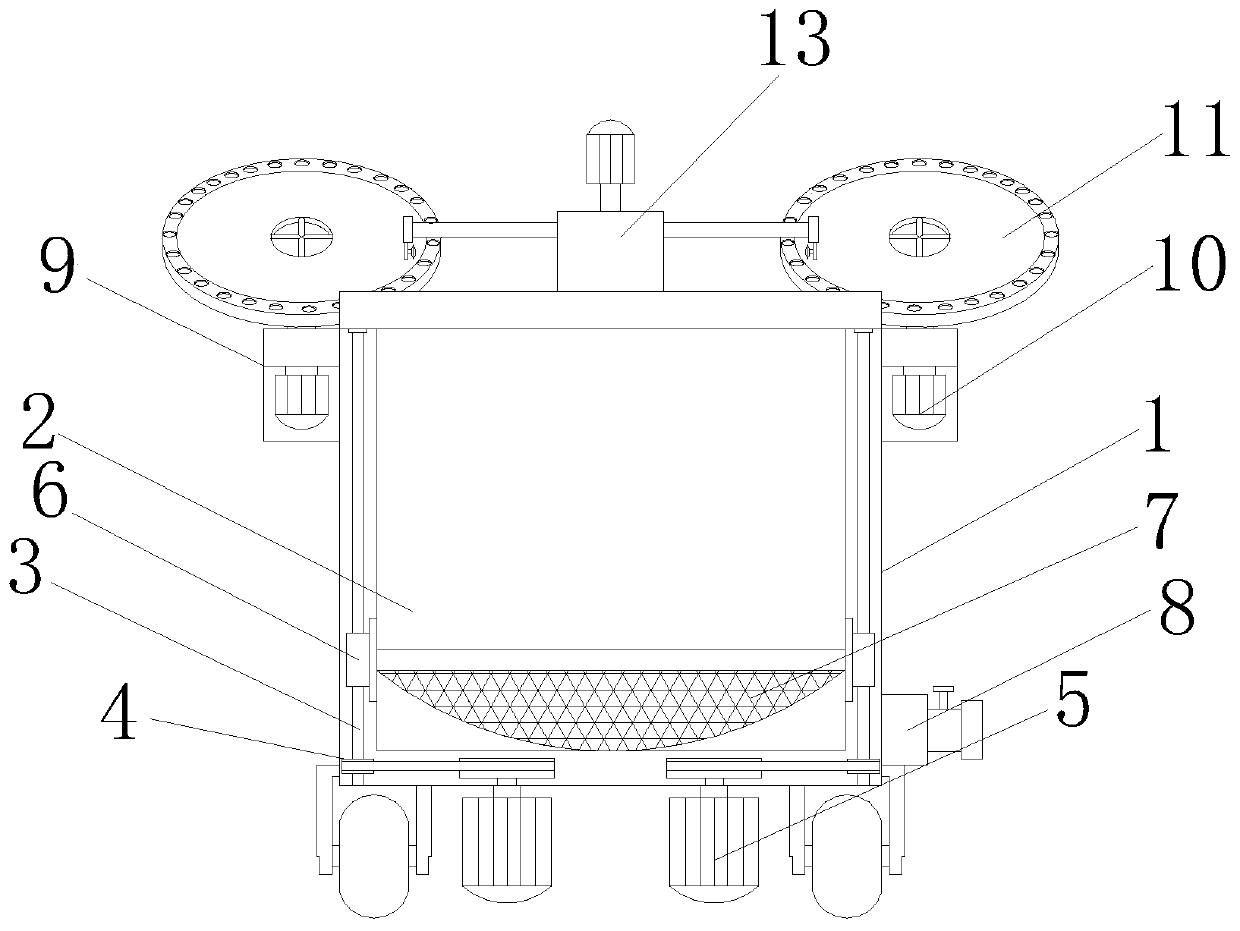

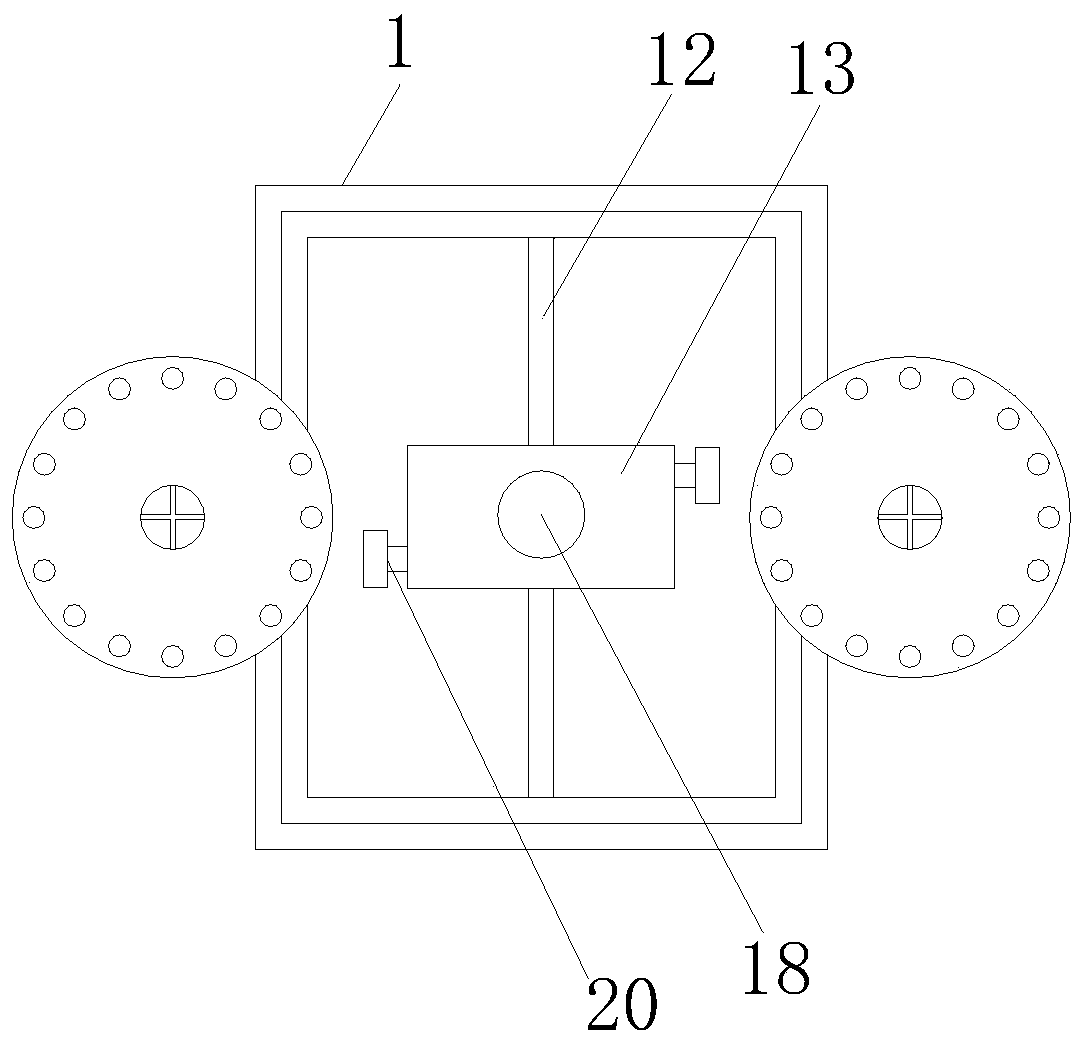

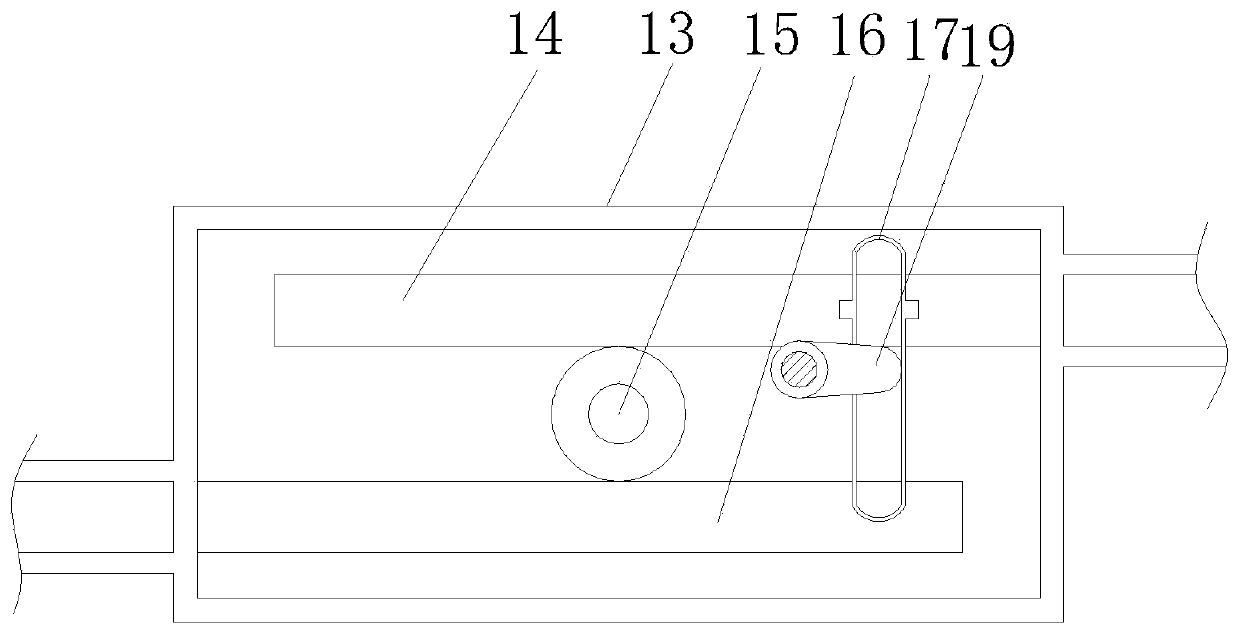

[0026] Example 1, such as Figure 1-4 When collecting eggs, start the second motor 10 and drive the placement plate 11 to rotate through the rotation of the output end of the second motor 10. At this time, the breeder picks up the eggs and places them in the groove provided on the placement plate 11, and at the same time Start the third motor 18, through the rotation of the output end of the third motor 18, the rotating block 19 is driven to move inside the transmission frame 17, and the rotation of the rotating block 19 cooperates with the transmission frame 17 to drive the first rack bar 14 to work inside the chassis 13. reciprocating motion in a straight line, and then use the meshing effect between the first rack bar 14 and the gear 15 to cooperate with the meshing effect between the gear 15 and the second rack bar 16, so that the second rack bar 16 can cooperate with the first rack bar 16. The linear reciprocating motion in the direction of the bar 14, along with the move...

Embodiment 2

[0027] Example 2, such as figure 1 , when the eggs fall into the water tank 2, under the influence of buoyancy, the eggs slowly sink and are washed by salt water at the same time. The runner 4 drives the threaded rod 3 to rotate, and the threaded rod 3 passes through the thread action between the moving block 6, and then drives the net 7 to move upwards to salvage the eggs, and at the same time, the valve 8 is opened to release the sewage inside the water tank 2. During the sinking process of the egg, the dirt on the surface of the egg is cleaned with salt water, and at the same time, the microorganisms on the surface are sterilized by the salt water, which is helpful for the preservation of the egg.

[0028]Working principle: When collecting eggs, start the second motor 10 and drive the placement plate 11 to rotate through the rotation of the output end of the second motor 10. At this time, the breeder picks up the eggs and places them in the groove set on the placement plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com