Printing ink stirring device

A technology of stirring device and ink, applied in the directions of mixer accessories, transportation and packaging, dissolving, etc., can solve the problems of low stirring efficiency of ink stirring device, and achieve the effect of improving stirring efficiency and improving stirring quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

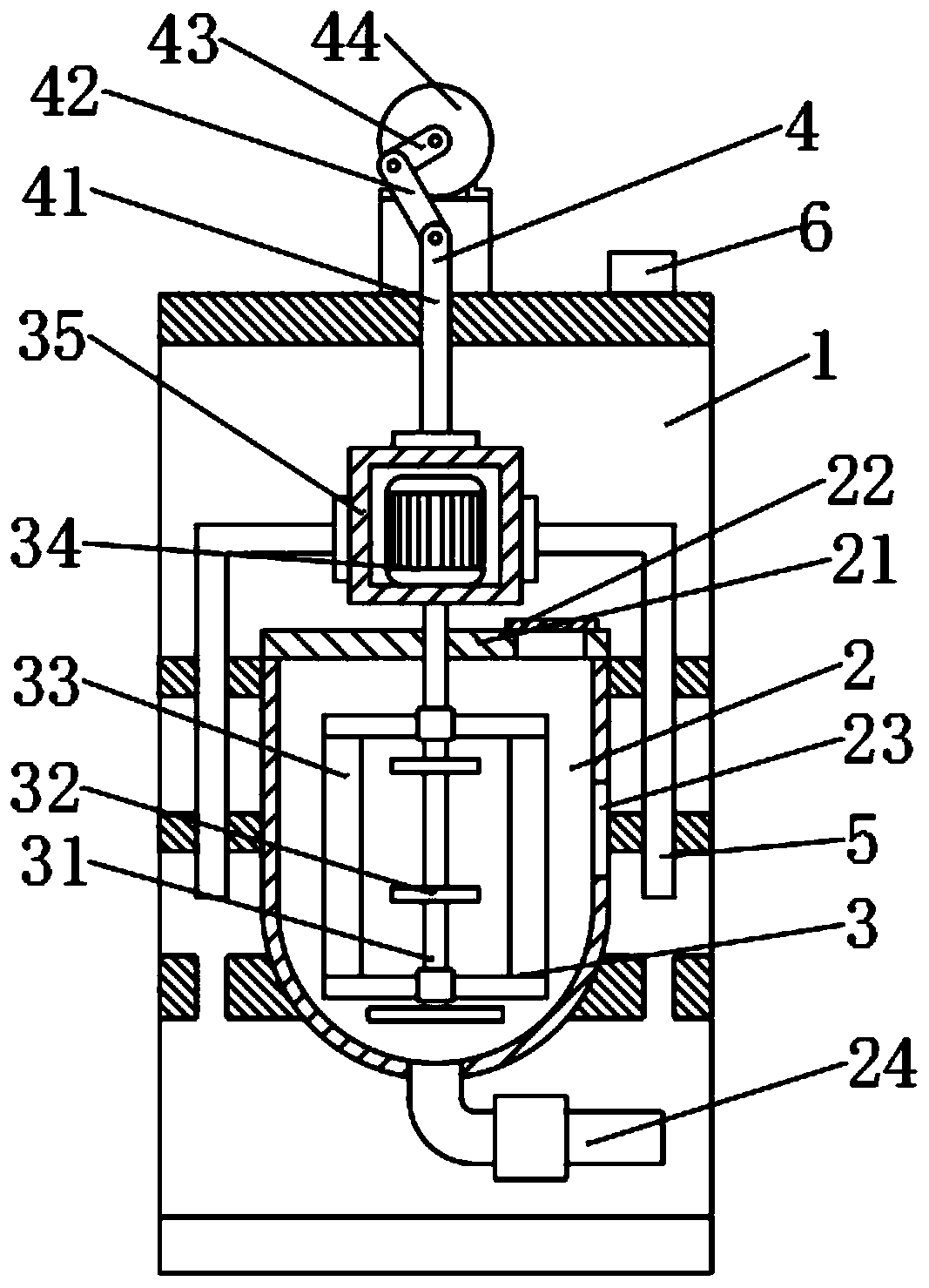

[0023] Depend on figure 1 As shown, a kind of ink stirring device comprises a support base 1, a stirring tank 2 and a timer 6 are fixedly connected to the support base 1, a rotating stirring unit 3 is arranged in the stirring tank 2, and a stirring motor 34 on the rotating stirring unit 3 is connected with The timer 6 is fixedly connected, and the side of the stirring tank 2 is provided with an observation window 23. The stirring tank 2 is also provided with an up and down stirring unit 4 for driving the rotating stirring unit 3 to move up and down. The push plate 32 for the material to roll up and down, the rotating stirring unit 3 is fixedly connected to the upper and lower stirring unit 4, and the upper and lower stirring unit 4 is fixedly connected to the support base 1;

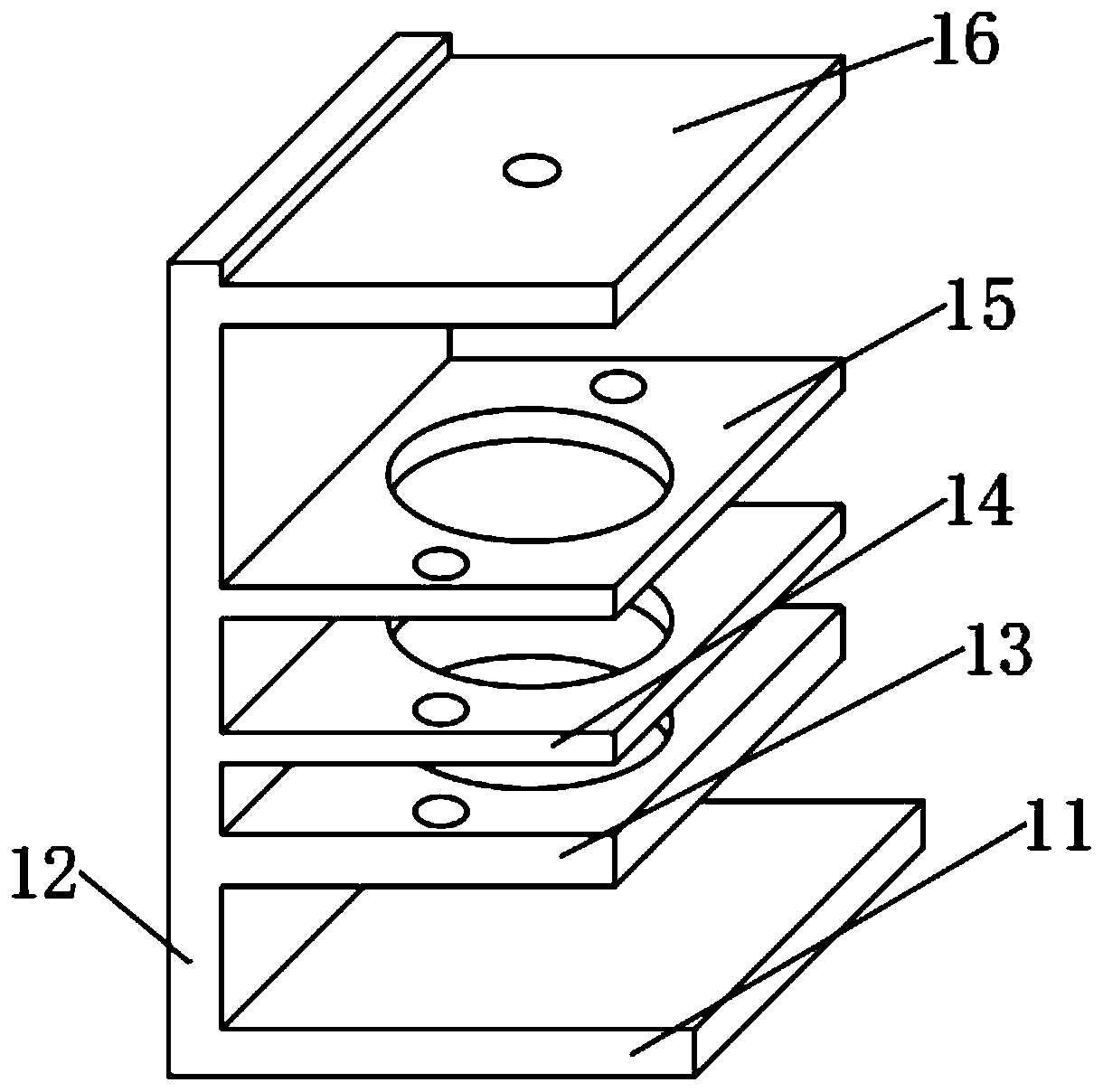

[0024] like image 3 As shown, the support seat 1 includes a bottom support seat 11 and a side support plate 12, the bottom support seat 11 and the side support plate 12 are arranged in an L shape, and ...

Embodiment 2

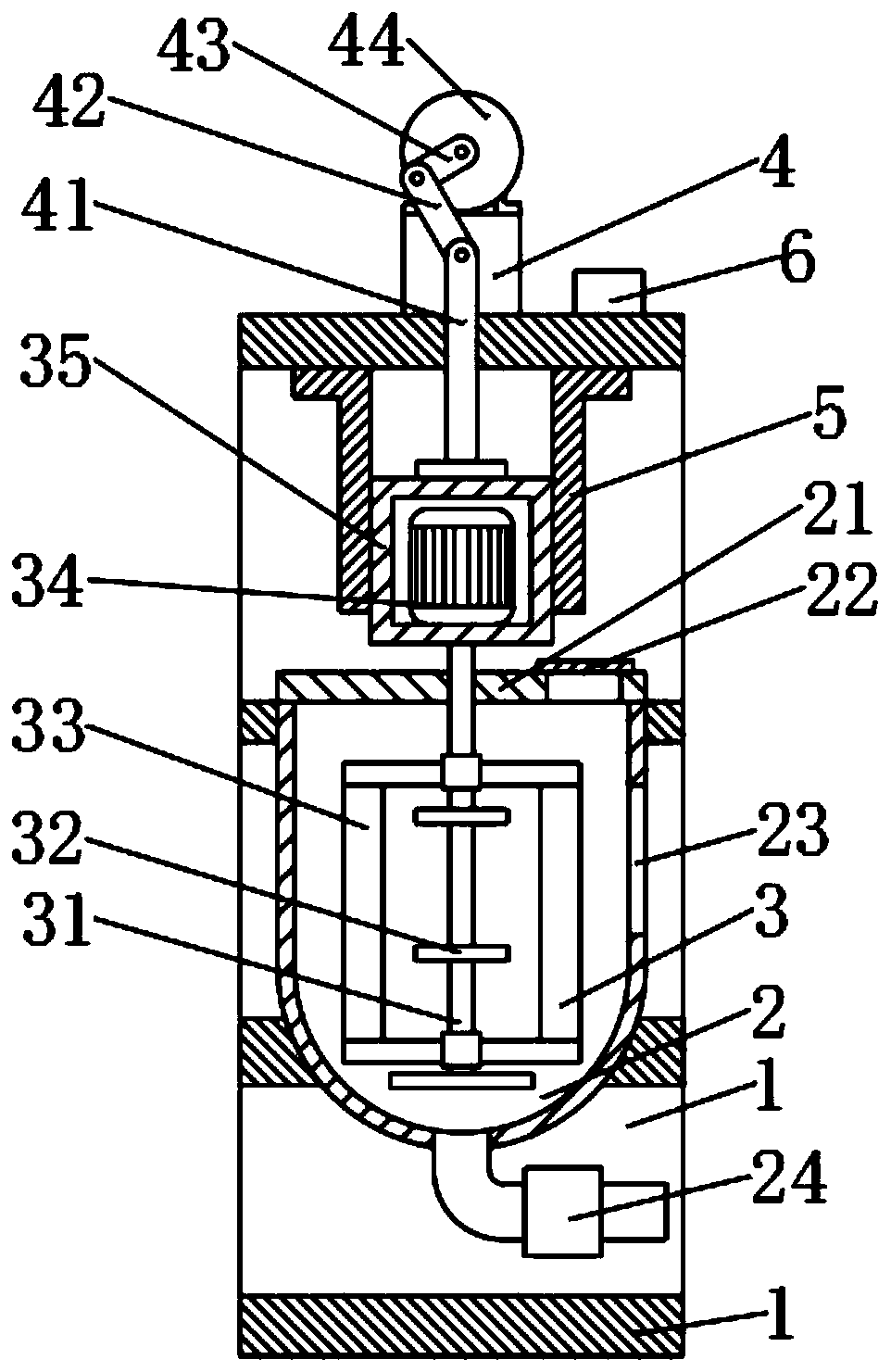

[0033] Depend on figure 2 As shown, a kind of ink stirring device comprises a support base 1, a stirring tank 2 and a timer 6 are fixedly connected to the support base 1, a rotating stirring unit 3 is arranged in the stirring tank 2, and a stirring motor 34 on the rotating stirring unit 3 is connected with The timer 6 is fixedly connected, and the side of the stirring tank 2 is provided with an observation window 23. The stirring tank 2 is also provided with an up and down stirring unit 4 for driving the rotating stirring unit 3 to move up and down. The push plate 32 for the material to roll up and down, the rotating stirring unit 3 is fixedly connected to the upper and lower stirring unit 4, and the upper and lower stirring unit 4 is fixedly connected to the support base 1;

[0034] In this embodiment, the limiting unit 5 is an L-shaped metal plate, and the limiting unit 5 is fixedly connected to the bottom of the fourth support plate 16. There are two limiting units 5, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com