Gravity type roller crushing and separating machine

A separator and gravity-type technology, which is applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of reducing product quality and crushing efficiency, and can not discharge fine materials, so as to achieve the effect of improving quality and crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

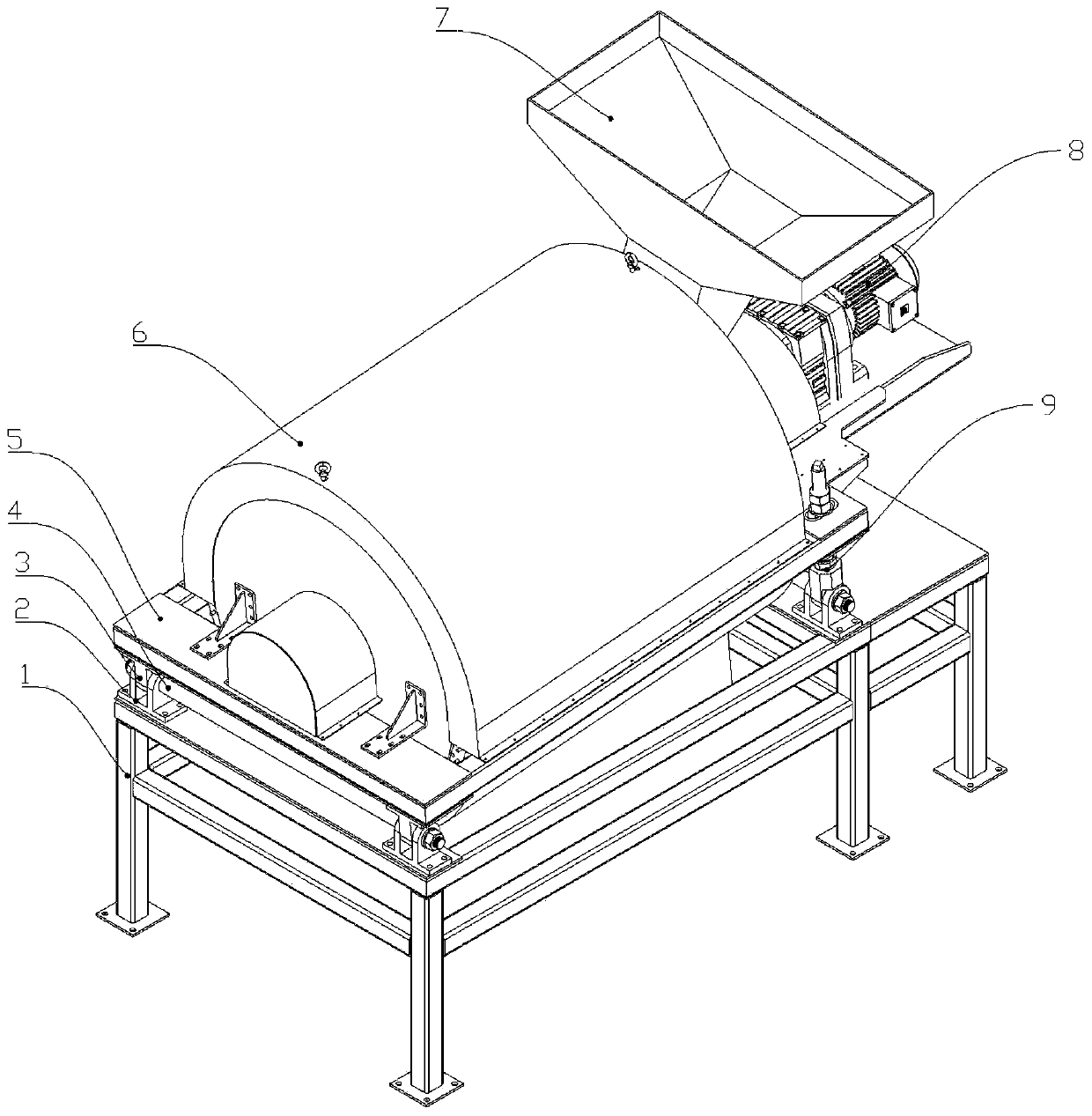

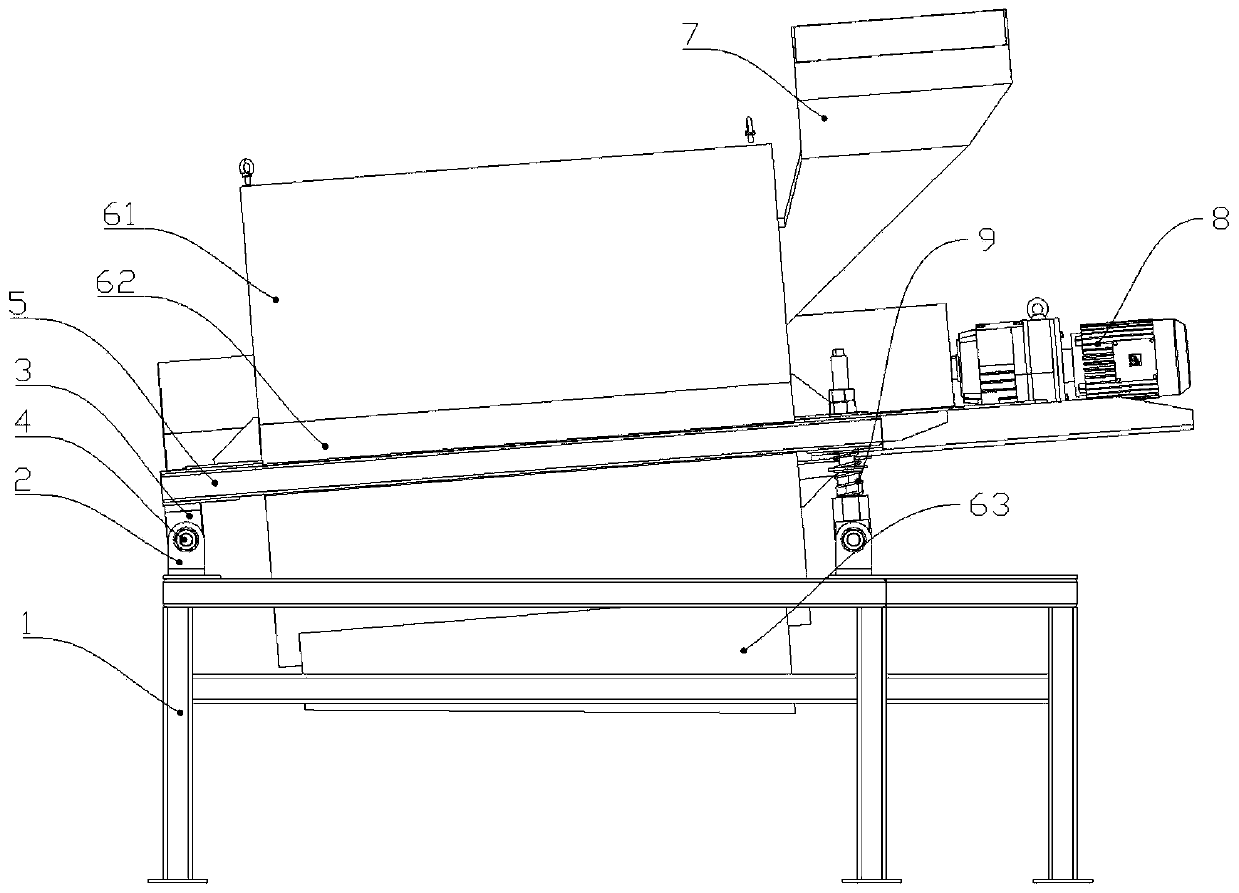

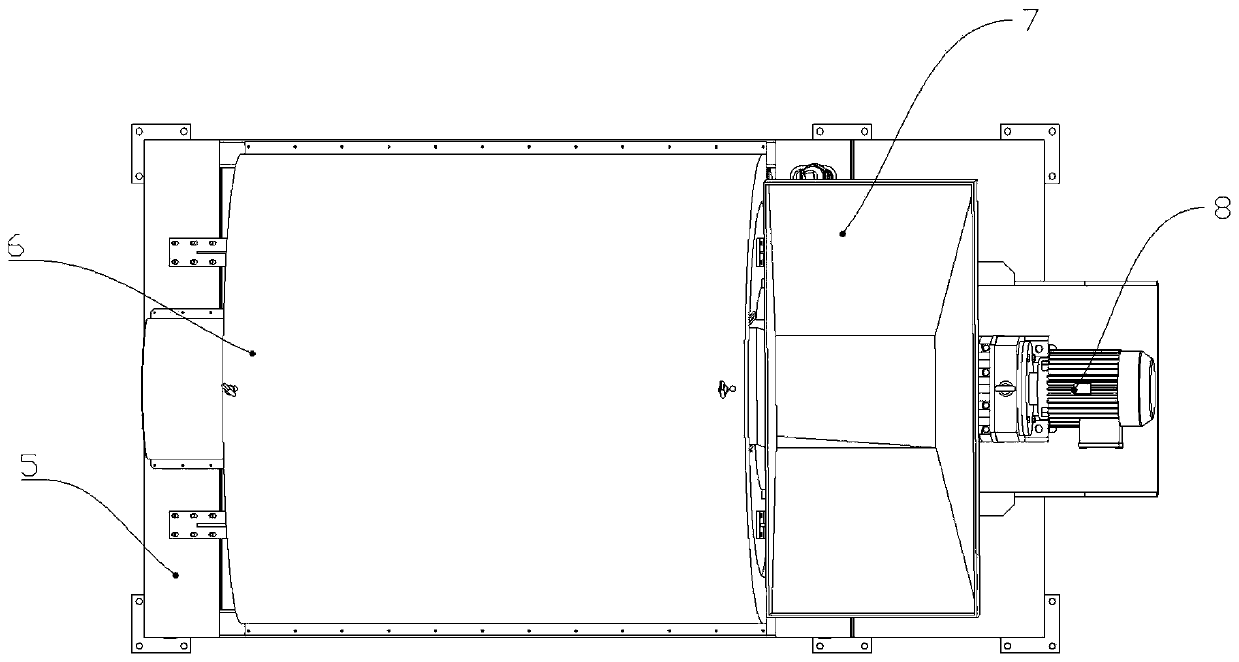

[0037] Such as Figure 1-11 As shown, a gravity drum crushing and separating machine includes a support frame assembly, a rotating mechanism 8 is installed on one side of the top surface of the supporting frame assembly, and a right flange 10 is connected to the end surface of the rotating mechanism 8, and a right flange 10 is installed on the right flange 10. Mesh sieve cylinder 11, the other end of the mesh sieve cylinder 11 is connected with a left flange 16, a crushing mechanism located in the mesh sieve cylinder 11 is installed between the left flange 16 and the right flange 10, and the side of the left flange 16 is connected with a The driving shaft 13 and the driven shaft 13 are installed in the bearing 14 on the other side of the support frame assembly. The support frame assembly is equipped with a cover assembly covering the screen cylinder 11. The lower end of the cover assembly has a discharge groove 621 to support The right closing part that can close the right fla...

Embodiment 2

[0040] Such as Figure 1-11 As shown, on the basis of the above-mentioned embodiments, this embodiment provides a preferred structure of the crushing mechanism. That is, the crushing mechanism includes a collision plate 17 and a collision bar 18 installed between the left flange 16 and the right flange 10. With the rotation of the screen cylinder 11, finished products such as alloy balls collide with the collision plate 17 and the collision bar 18 to form a crushing mechanism. Finished products such as alloy balls are broken.

[0041] Preferably, the number of collision plates 17 and collision bars 18 is multiple, and a plurality of collision bars 18 and a plurality of collision plates 17 are all evenly installed on the inner wall of the screen cylinder 11, so that when the screen cylinder 11 rotates, , The collision plate 17 and the collision rod 18 can evenly impact finished products such as alloy balls.

[0042] The remaining parts are the same as those in Embodiment 1, so ...

Embodiment 3

[0044] Such as Figure 1-11 As shown, on the basis of the above embodiments, this embodiment provides a preferred structure of the rotating mechanism. That is, the rotating mechanism 8 includes a motor 81 installed on the top surface of the support frame assembly, the motor 81 is connected with a drive shaft 82 , the drive shaft 82 is connected with a right end 83 , and the right end 83 is connected with the right flange 10 . The rotation of the motor 81 drives the driving shaft 82 to rotate, and the rotation of the driving shaft 82 drives the right end 83 and the right flange 10 to rotate in turn, and the right flange 10 drives the screen cylinder to rotate again.

[0045] Preferably, the right closure includes a right end plate 12 installed on the support frame assembly, the middle part of the right end plate 12 has a round hole 121, and the main shaft passes through the round hole 121; the left closure includes a left end plate installed on the support frame assembly 19. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com