Damping face milling cutter with adaptive instantaneous change of tooth pitch and cutting speed

A cutting speed and instantaneous change technology, applied in the field of machining tools, can solve problems such as increasing the stiffness of the process system, self-excited vibration of the process system, reducing the precision and quality of the cutting surface, tool life, equipment durability, and processing efficiency, etc., to achieve Effect of reducing self-excited vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

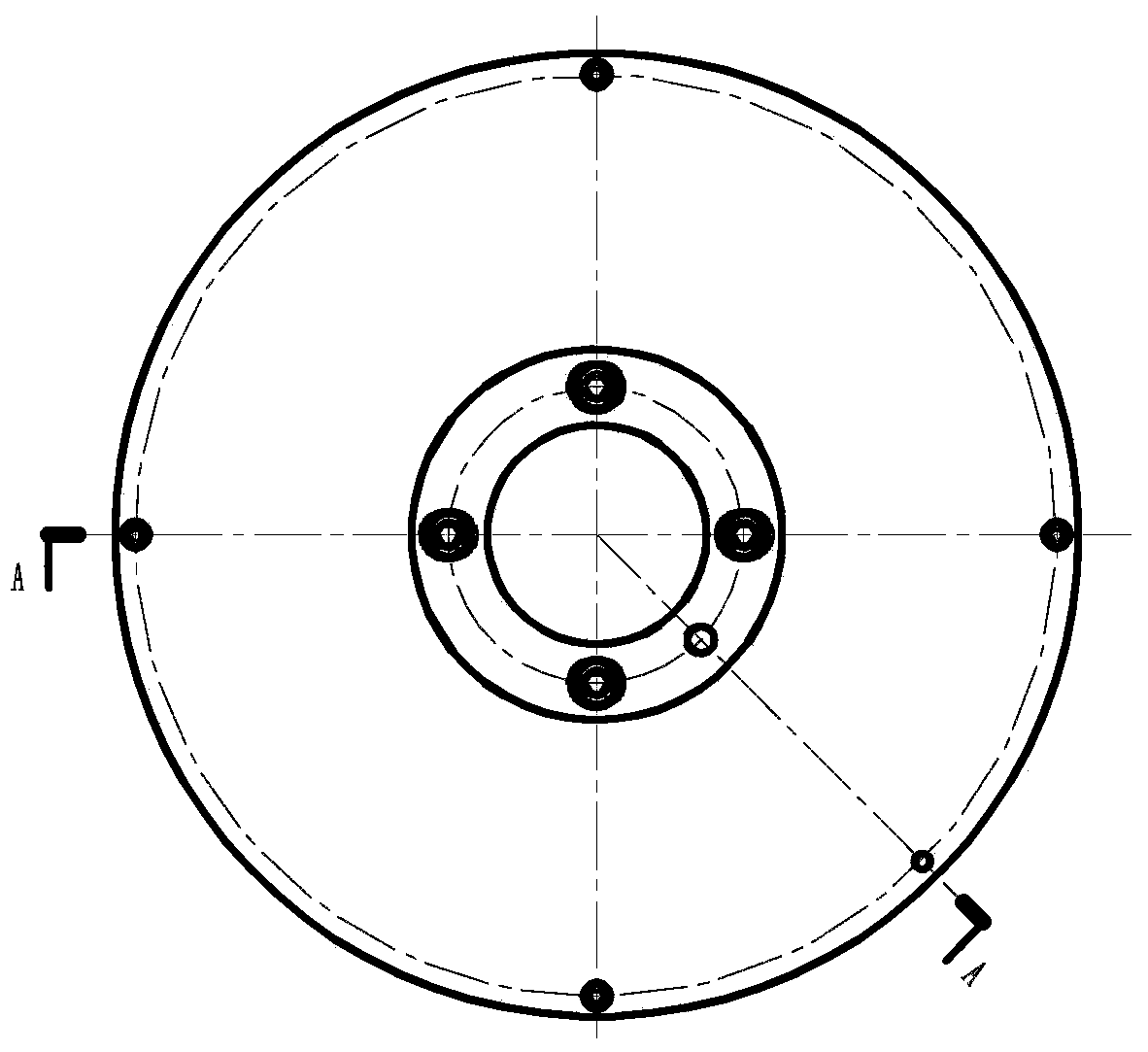

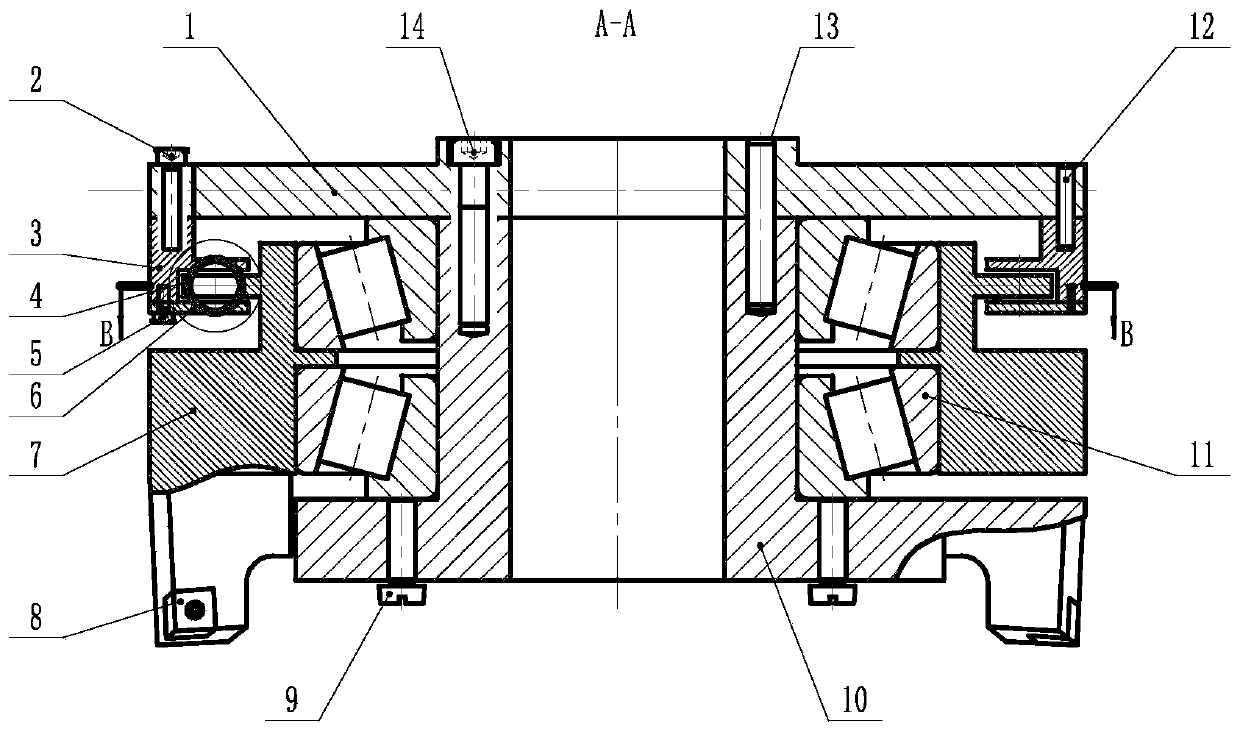

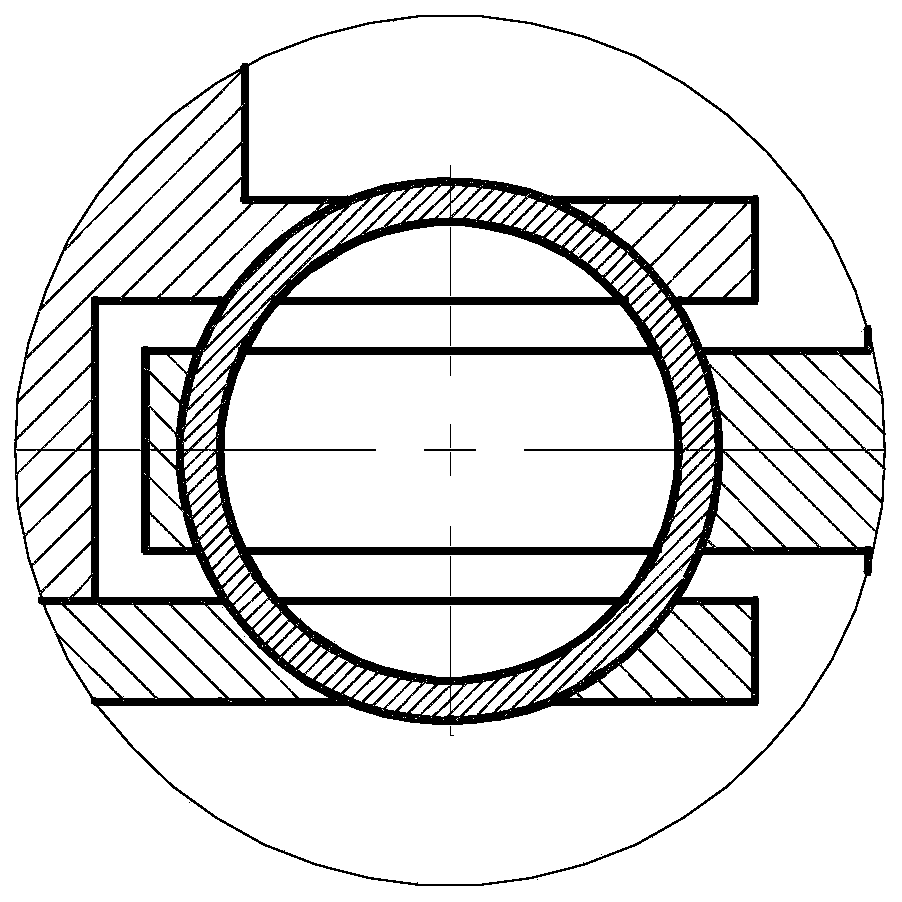

[0036] This embodiment provides a vibration-damping face milling cutter whose tooth pitch and cutting speed can be adaptively changed instantaneously, including a cutter body. The cutter body includes an outer cutter body 7, an inner cutter body 10 and a connecting outer cutter body 7, The bearing 11 of the inner cutter body 10; the outer cutter body is cylindrical, and the inner and outer sides of the outer cutter body have bosses, and the bosses on the inner side of the outer cutter body are used to contact the bearings, and the bearings can The boss on the inner side of the outer cutter body is tightened to clamp the outer cutter body, and the boss on the outer side of the outer cutter body is used to connect the spring.

[0037] Also includes a flange, the flange includes a flange body and a bottom cover 6 connected to the flange body, the top of the flange body is connected to the flange side 3 by a fastening bolt, and the flange cover is connected by a cylindrical pin It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com