Micro-nano porous throttling static pressure air flotation cylindrical bearing

A cylindrical bearing, micro-nano technology, applied in the direction of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems that restrict ultra-compact machining, ultra-precision positioning, weak stiffness, micro-vibration, etc., to improve dynamic characteristics and reduce self-excitation Vibration, high stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to describe the technical means and advantages of the present invention in more detail, the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings. The embodiments described here are only illustrative, not limiting, and the protection scope of the present invention is not limited by these embodiments.

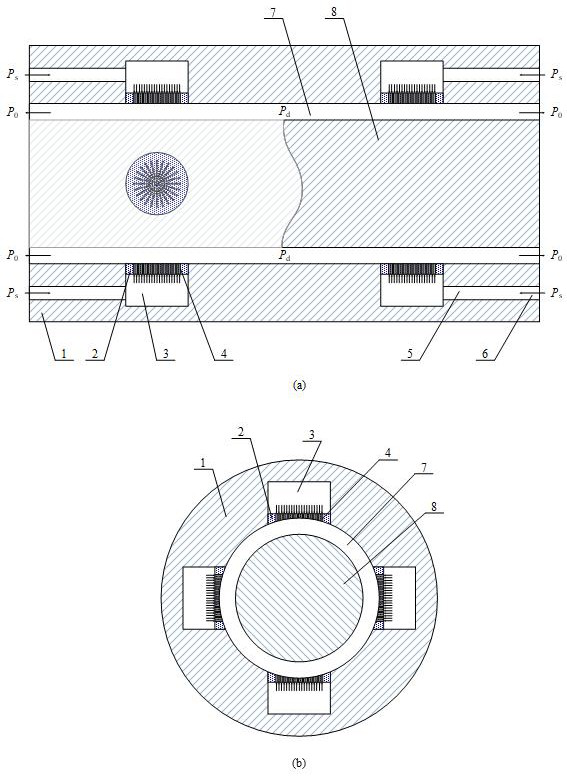

[0018] figure 1 It is a structural schematic diagram of the micro-nano porous throttling static pressure air bearing spherical bearing constructed according to the preferred embodiment 1 of the present invention.

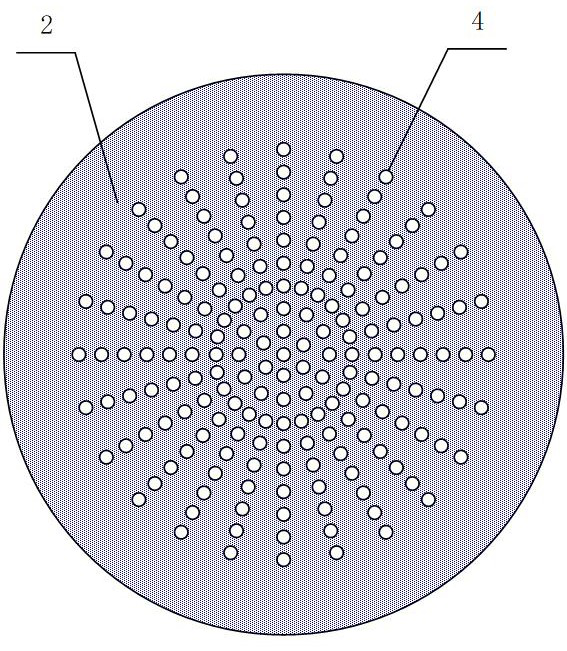

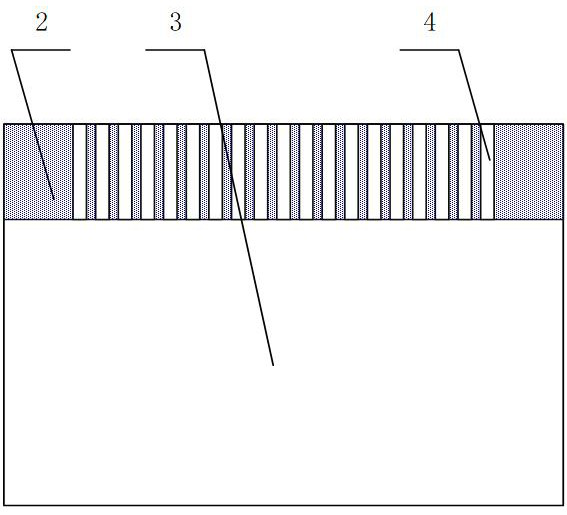

[0019] like figure 1 As shown, the micro-nano porous throttling static pressure air-bearing cylindrical bearing includes three parts: the air-floating cylindrical bearing body (1), the micro-nano porous throttle (2) and the cylindrical support member (7).

[0020] like figure 1 As shown, high-pressure gas flows into the gas channel (5) along the air inlet (6), passes through the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com