A porous and microporous combined throttle gas hydrostatic turning electric spindle

A gas static pressure, porous technology, applied in the direction of manufacturing tools, metal processing machinery parts, positioning devices, etc., can solve the problems of small bearing capacity, long flow of pressurized gas, and reduced rigidity of the static pressure spindle, so as to improve the bearing capacity Effects of force and stiffness, reduction of self-excited vibration, and faster response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

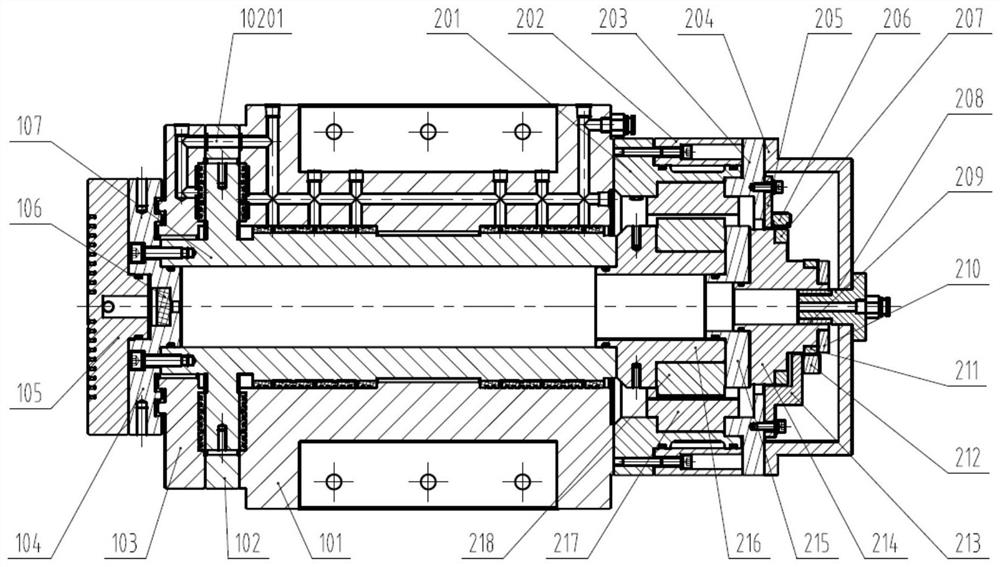

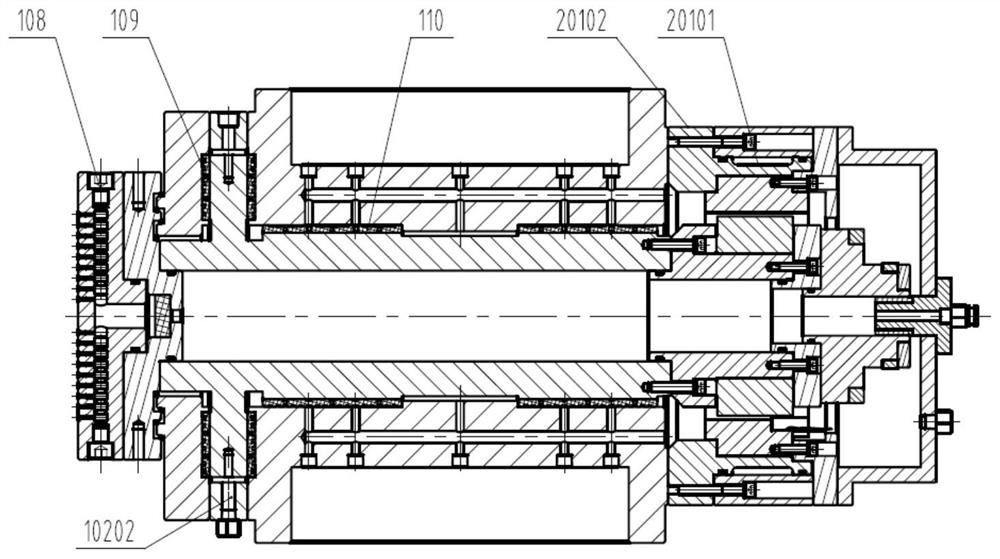

[0045] This embodiment is combined with the attached Figures 1 to 15 The porous and microporous combined throttle gas hydrostatic turning electric spindle of the present invention is described in detail.

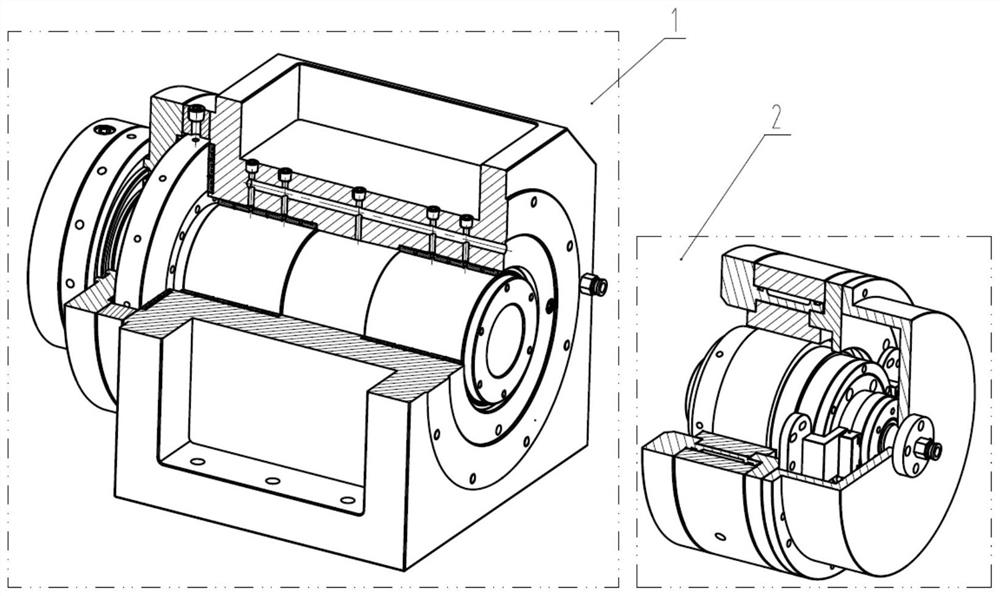

[0046] The porous and microporous combined throttle gas hydrostatic turning electric spindle of the present invention includes an air flotation support assembly 1 and a drive assembly 2, wherein figure 1 The left figure in the figure is a schematic diagram of the structure of the air flotation support assembly 1, figure 1 The figure on the right in the middle is a schematic diagram of the structure of the drive assembly 2; the air flotation support assembly 1 consists of a base 101, a backing ring 102, a thrust plate 103, a chip shield 104, a suction cup 105, a filter plug 106, a rotating shaft 107, and two air blocking Rod 108, 2 axial throttles 109 and 2 radial throttles 110, the drive assembly 2 consists of a stator mounting piece 201, a cooling sleeve 202, a stator pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com