A high-precision wood-panel sander that can be polished on both sides at the same time and its working method

A double-sided polishing, high-precision technology, used in grinding/polishing equipment, grinding/polishing safety devices, manufacturing tools, etc. Improve the efficiency of polishing work, improve the polishing accuracy, and improve the effect of the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

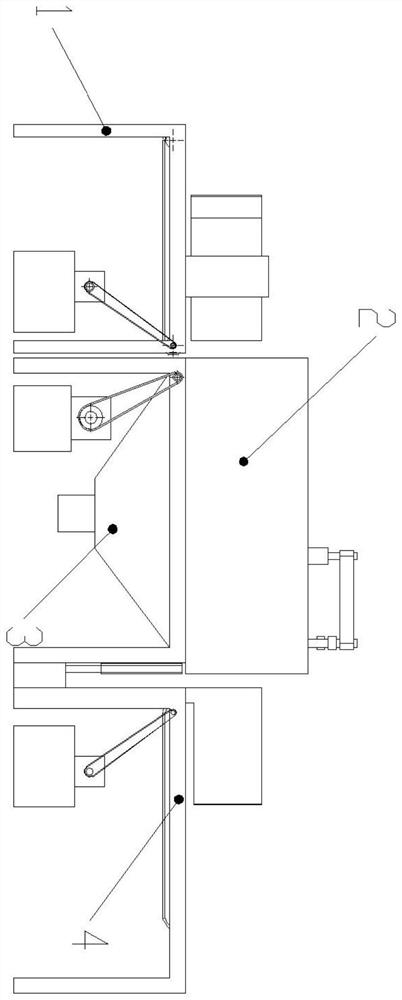

[0034] like figure 1 Shown is a front view of the present invention, including a feed structure 1, a double-sided polishing structure 2, a discharge structure 3 and a dust collection structure 4, and the double-side polishing structure 2 is arranged on the feed structure 1 and the discharge structure 3 At both ends, the dust collection structure 4 is arranged at the lower end of the double-sided polishing structure 2 .

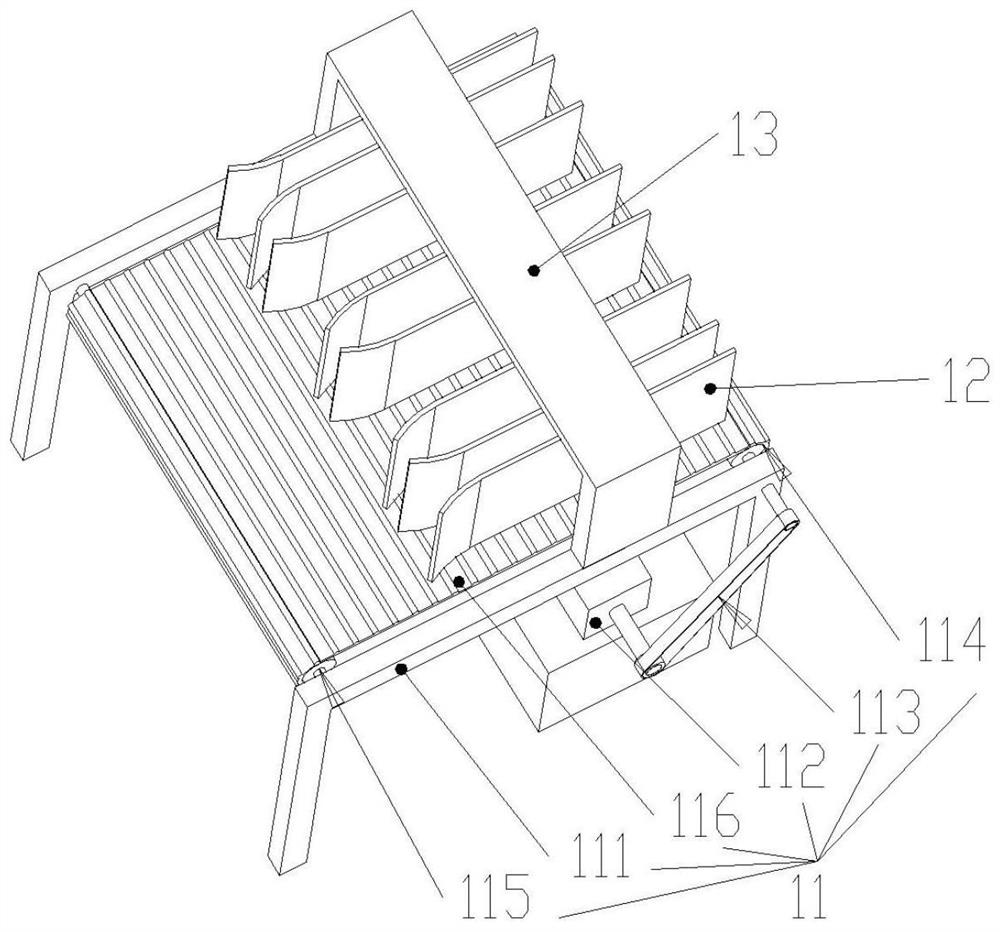

[0035] like figure 2Shown is a perspective view of the feed structure 1, including a feed conveyor structure 11, a feed guide structure 12 and a feed limit frame 13, and the feed guide structure 12 is arranged above one end of the feed conveyor structure 11 , the feed limiting frame 13 is arranged at one end of the feed conveyor belt structure 11 above the feed guide structure 12 .

[0036] The feed conveyor belt structure 11 includes a feed conveyor bracket 111, a feed power structure 112, a feed conveyor structure 113, a first feed conveyor roller 114, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com