Design and manufacturing method of a special-shaped polishing disc for a double-rotor CNC polishing machine

A production method and technology of polishing discs, which are applied in the direction of grinding/polishing equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of not being able to adapt to the production requirements of complex pattern polishing discs and low design optimization efficiency, so as to improve the polishing quality, The effect of shortening the polishing cycle and meeting the needs of differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

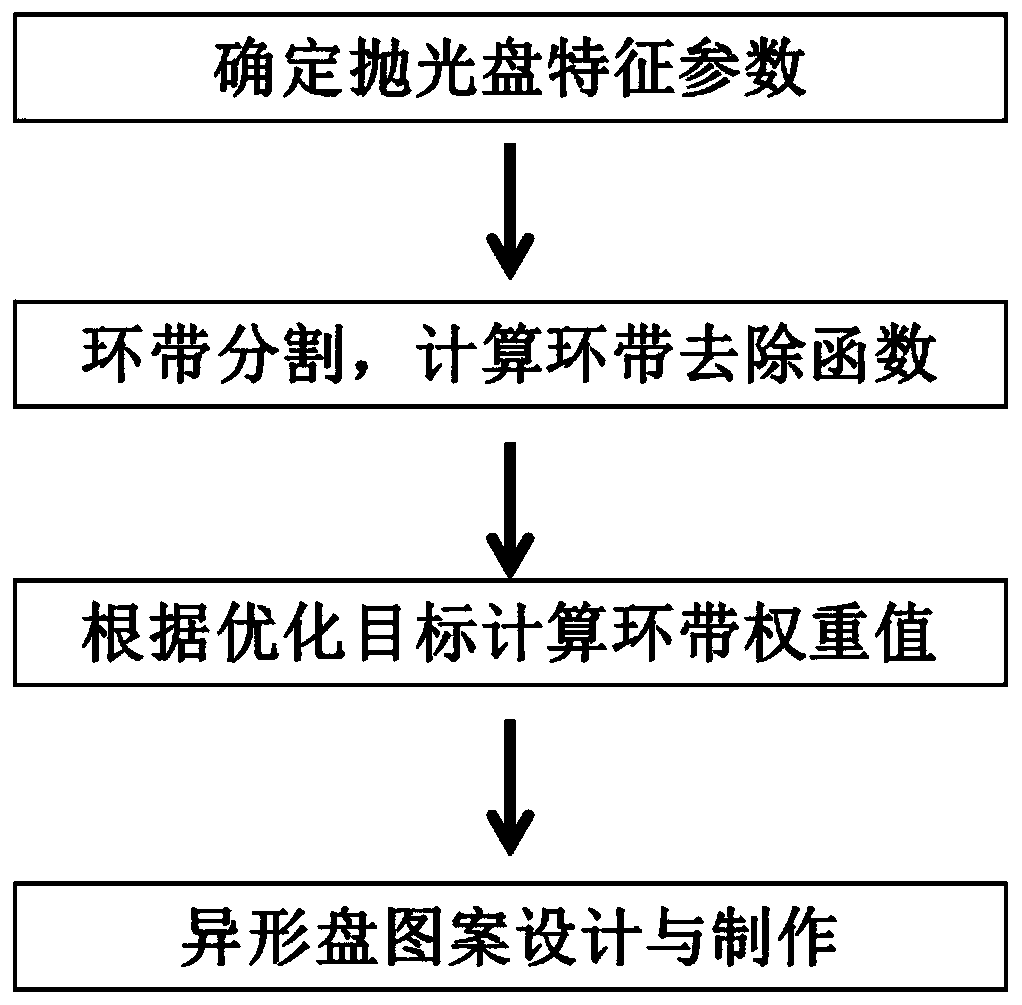

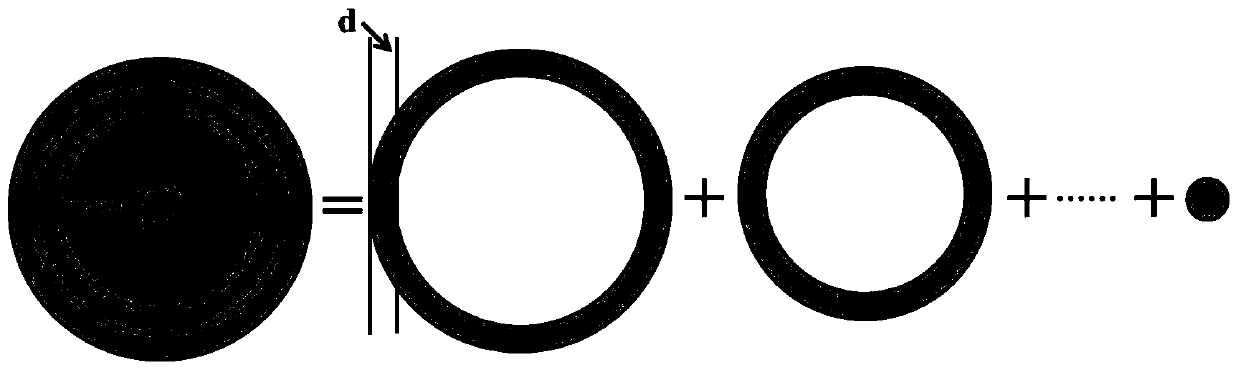

[0026] like figure 1 As shown, it is a flow chart of a method for designing and manufacturing a special-shaped polishing disc suitable for a double-rotor CNC polishing machine. The method includes the following steps:

[0027] (1) Determine the characteristic parameters of the polishing disc:

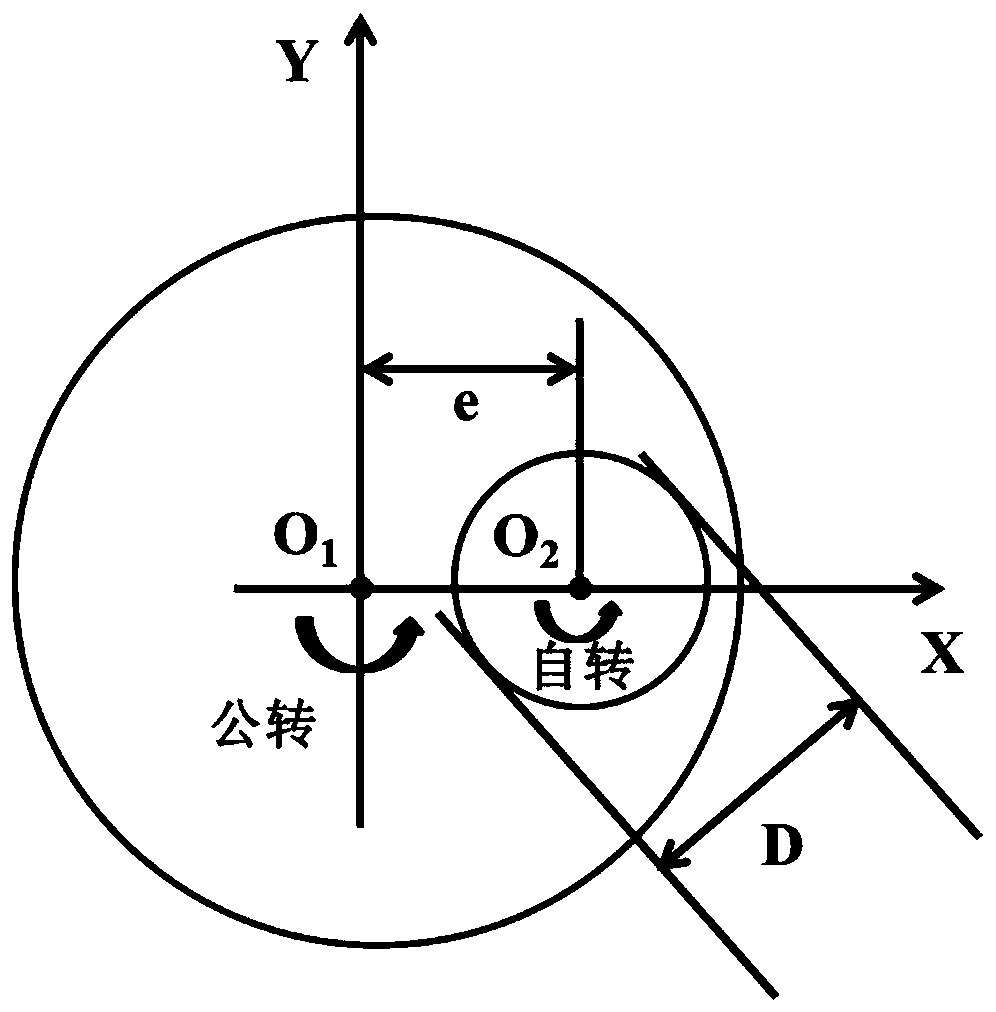

[0028] like figure 2 As shown, in the double-rotor CNC polishing machine, the polishing disc is in addition to the rotation axis O 2 In addition to the rotation, it also revolves around the revolution axis O 1 For rotation, the distance between the rotation axis and the revolution axis is the eccentricity. The characteristic parameters of the polishing disc movement include the processing parameter values such as the characteristic dimension D of the polishing disc, the eccentricity e, the rotation, and the revolution speed ratio m; among them, for a circular polishing disc, the characteristic dimension D is its diameter, and for other non-circular polishing discs, the characteris...

Embodiment 2

[0038] This embodiment provides a laser cutting device, which can be used for laser cutting of the opposite-shaped polishing disk in the foregoing embodiments. like Figure 5 As shown, the laser cutting device includes: a laser (1), the selection type of the laser includes CO2 laser, YAG laser, fiber laser, etc., and the laser adopts a continuous laser output mode and an electric excitation mode. By adjusting the laser power supply The excitation voltage and excitation current value change the energy of the output laser beam; the focusing lens (2) is used to condense the laser beam; The beam deflection angle realizes the precise movement and positioning of the beam in the working plane; the displacement platform (4) is used to carry the sample and realize the rough adjustment and positioning of the damping cloth polishing pad; the control computer (5) controls the breaking of the laser through the built-in software, In order to control the output energy of the laser and drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com