Aerodynamic heat source hot-pressing kettle

An aerodynamic and autoclave technology, applied in the field of aerodynamic heat source autoclave, can solve problems such as incapable of industrial high-efficiency production, and achieve the effects of improving basic industrial level, high heating efficiency, and no heat energy waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

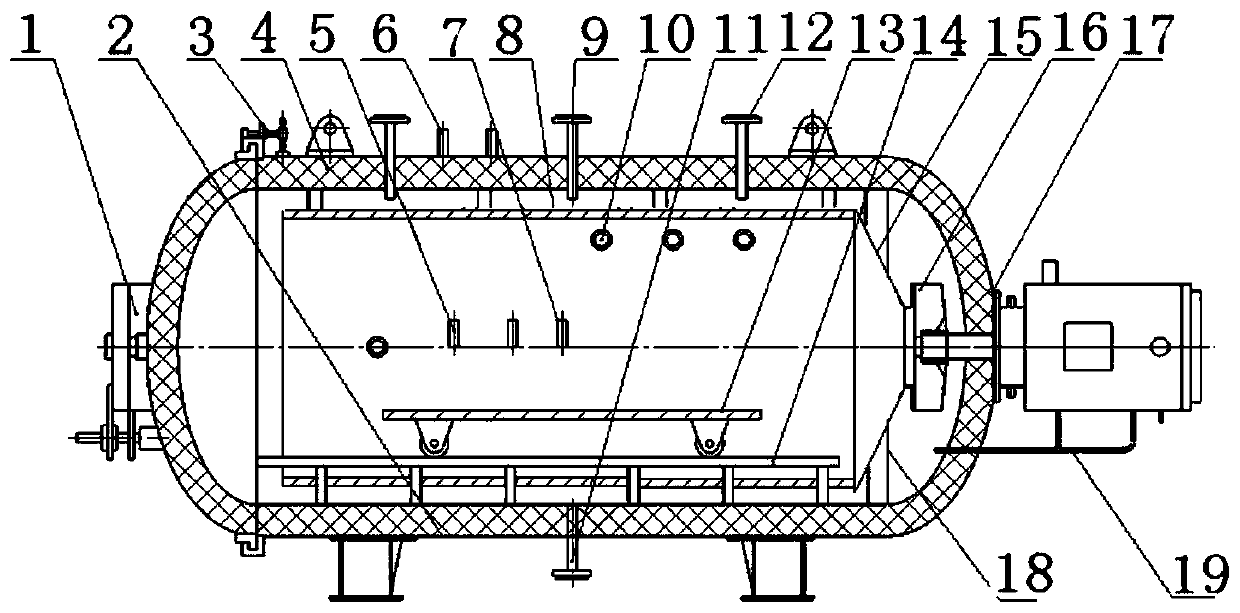

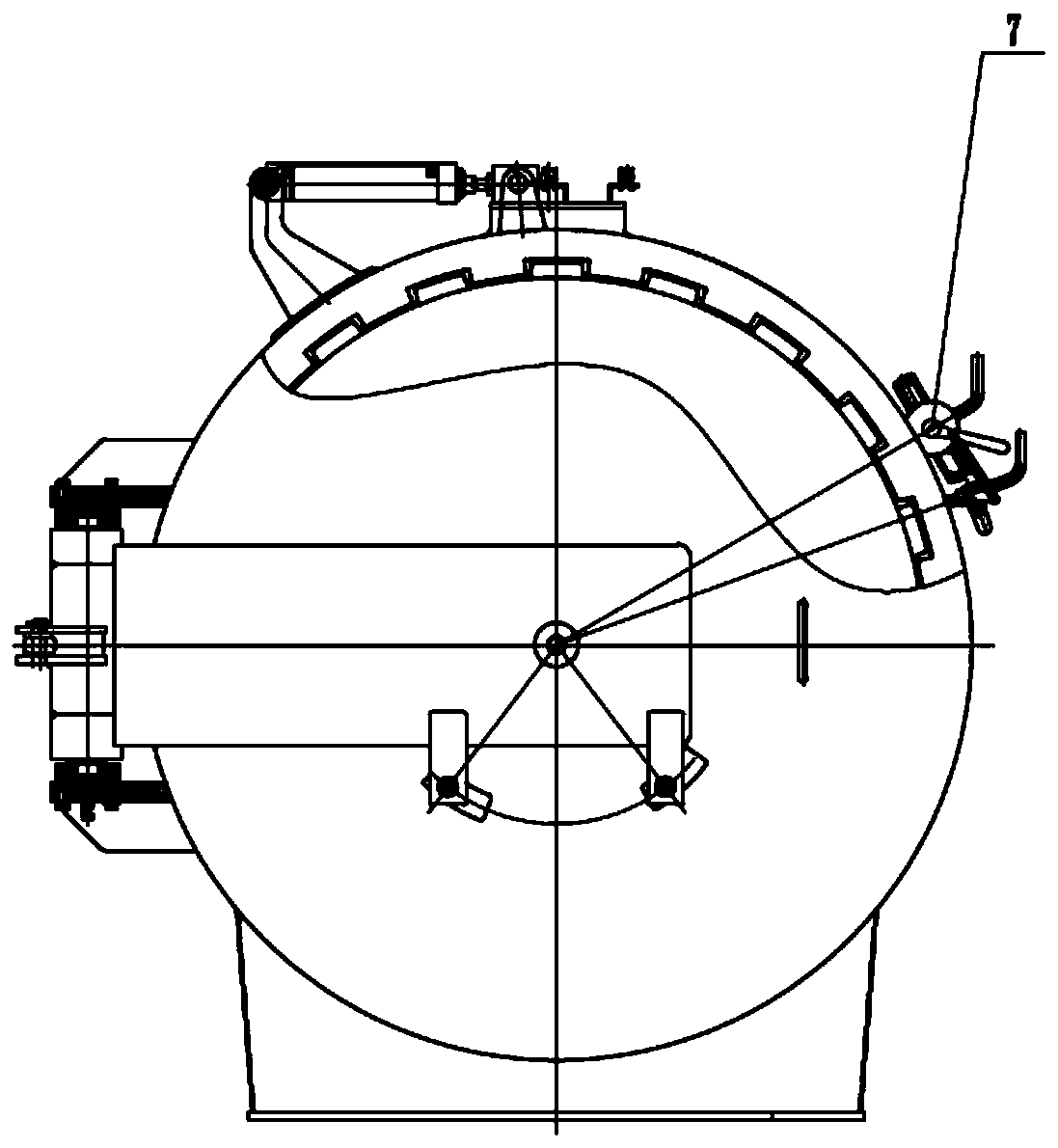

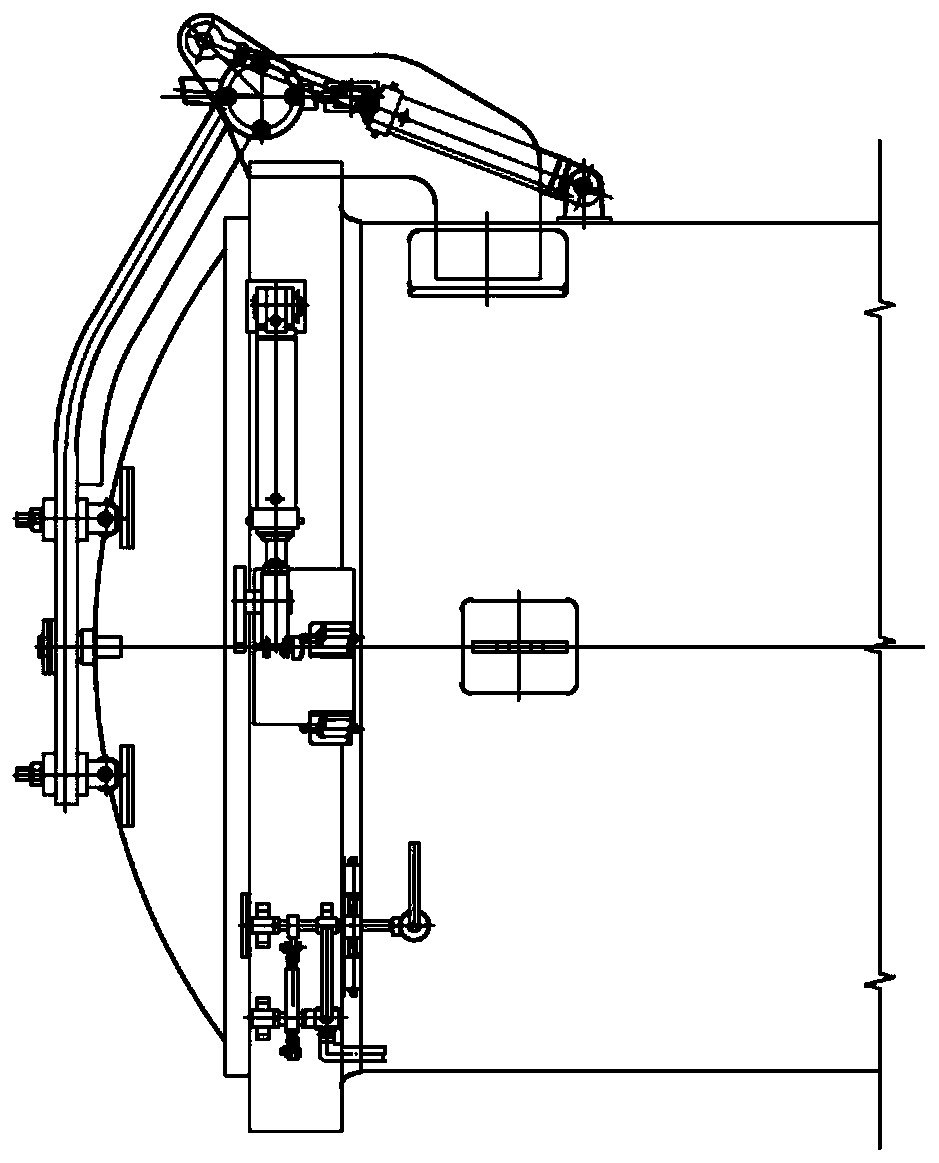

[0019] This embodiment is an autoclave of an aerodynamic heat source. It includes furnace door 1, autoclave body 2, frequency conversion motor, air guide cone 15, air guide tube 8, tank inner rail 14, product cart 13 and impeller 16. Wherein: the autoclave body 2 is a sealed tank body, and a furnace door 1 is installed on a furnace door at one end of the autoclave body. The frequency conversion motor is installed on the outer surface of the tank bottom at the other end of the autoclave body, and the output shaft of the frequency conversion motor is located in the tank body of the autoclave body; between the frequency conversion motor and the autoclave body The interface is sealed with a metal winding gasket 17; a balance pipe 19 is connected between the frequency conversion motor and the autoclave body, one end of the balance pipe is connected to the impeller chamber located in the autoclave body, and the other end is passed through The cooling water jacket of the frequency c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com