Large-capacity conveyor belt transport packaging structure

A packaging structure and conveyor belt technology, which is applied in the field of large-capacity conveyor belt transportation packaging structure, can solve the problems of time-consuming and labor-intensive joints, and achieve the effects of improving space utilization, good economy, and large transportation volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with specific embodiments.

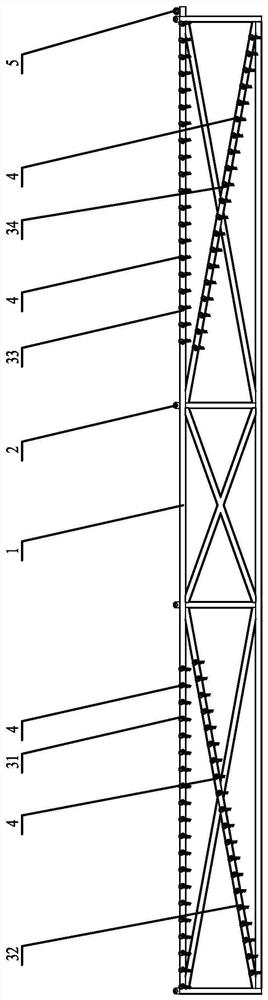

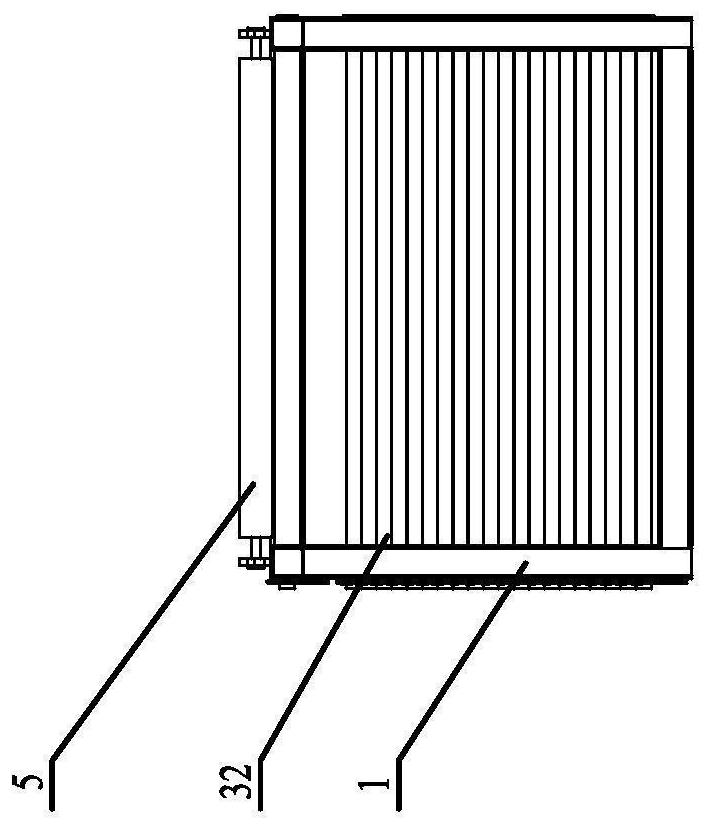

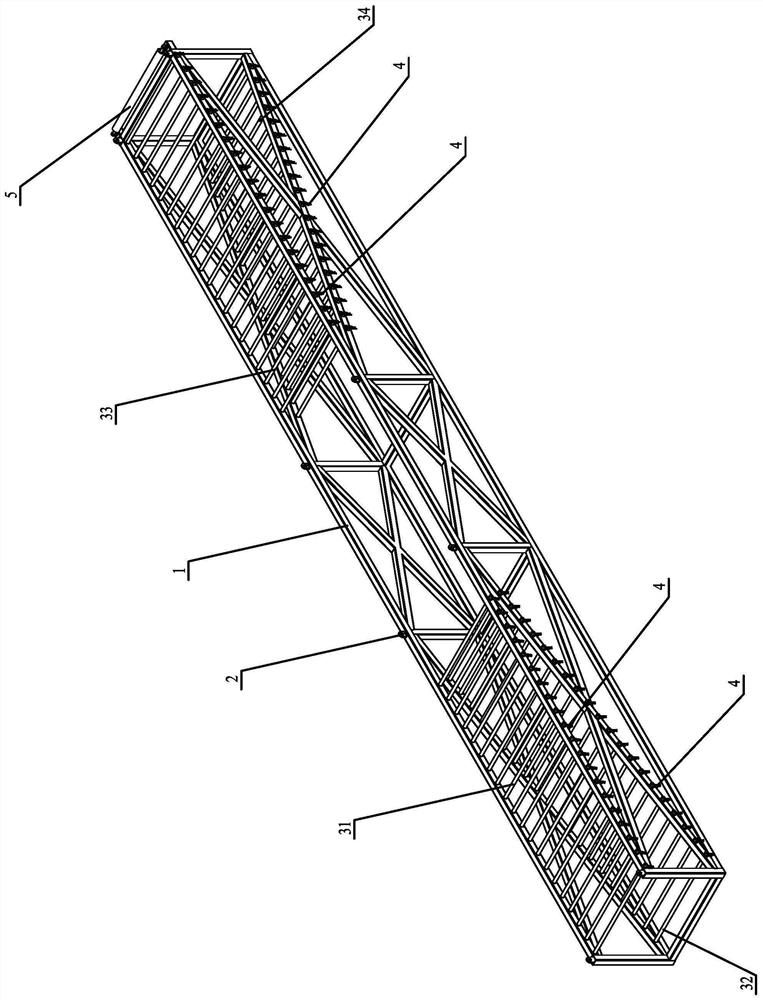

[0024] The large-capacity conveyor belt transportation packaging structure of the present invention includes a main frame 1, a lifting lug 2, a left horizontal positioning tube 31, a left inclined positioning tube 32, a right horizontal positioning tube 33, a right inclined positioning tube 34 and a positioning card 4;

[0025] A lifting lug 2 is fixed in the middle of the upper surface of the main frame 1 , a group of left horizontal positioning holes and left inclined positioning holes are opened on the main frame 1 on the left side of the lifting lug 2 , and a set of left horizontal positioning holes is inserted into the left horizontal positioning hole The left horizontal positioning tube 31, the positioning cards 4 are inserted at both ends of each left horizontal positioning tube 31, and the left inclined positioning tube 32 is inserted in the left inclined positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com