Automatic concrete pouring device for building construction

A technology for building construction and automatic pouring, which is applied to clay preparation devices, construction, and unloading devices. It can solve problems such as high work intensity, increased concrete viscosity, and uneven pouring, so as to save manufacturing and use costs and add water. Uniform, labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

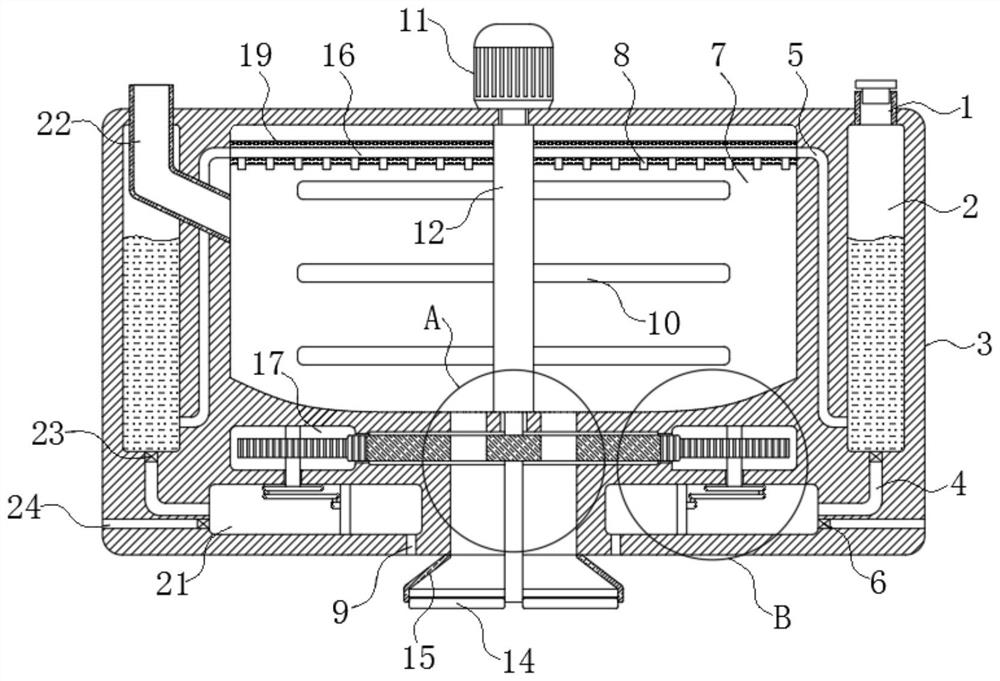

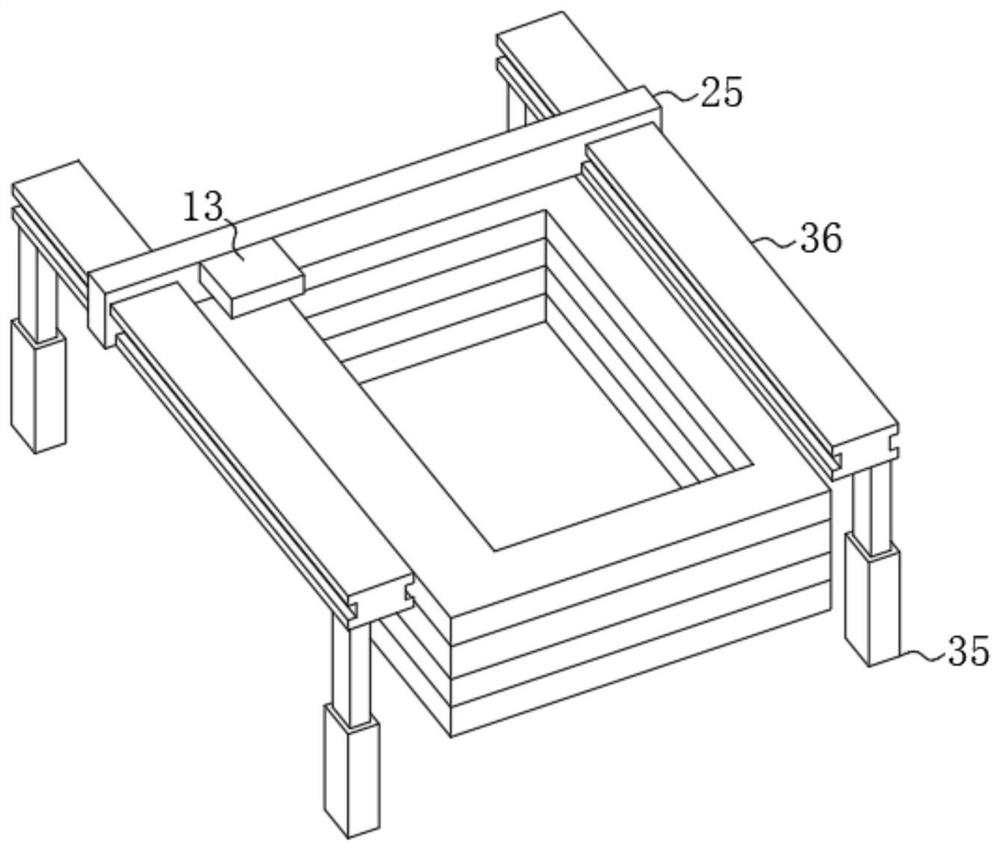

[0033] refer to Figure 1-6 , an automatic concrete pouring device for building construction, including two guide rails 36 fixed on the ground through two electric telescopic rods 35, a beam 25 sliding along the two guide rails 36, and a concrete pourer 13 slidingly connected to the beam 25 , a controller is installed on the guide rail 36, and a motion mechanism coupled with the controller is installed on the crossbeam 25 and the concrete pourer 13. The motion mechanism can be controlled by the controller to push the crossbeam 25 and the concrete pourer 13 to move. technology, so I won’t go into details here.

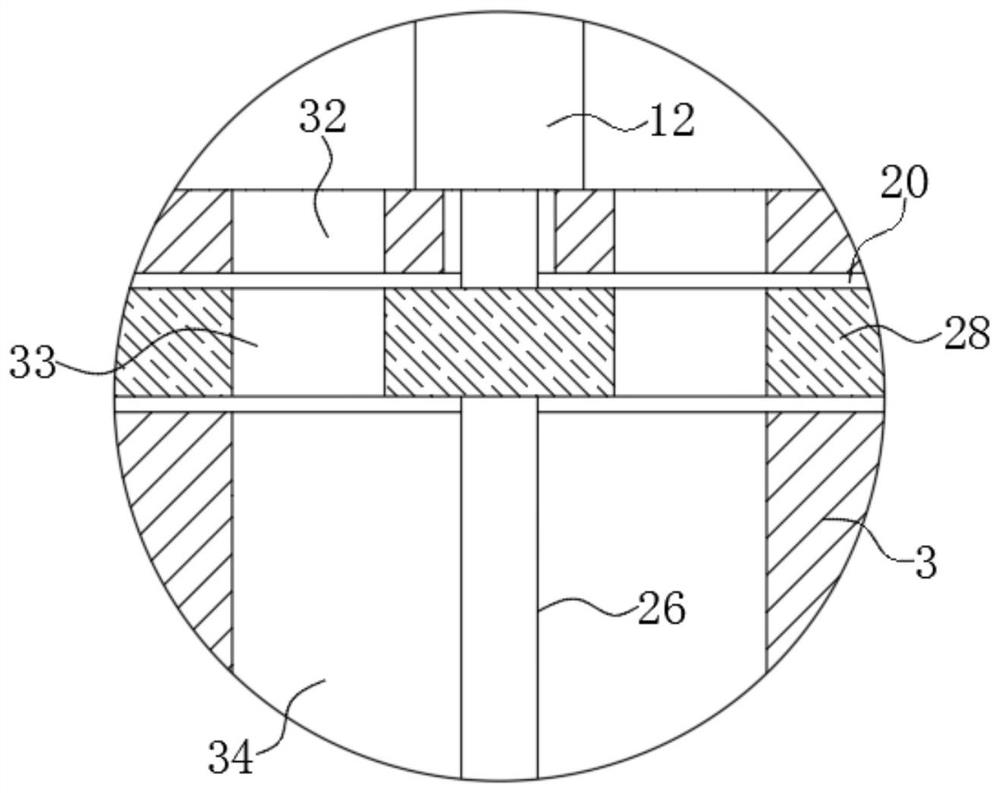

[0034]Concrete pourer 13 comprises pouring box 3, motor 11, stirring shaft 12 and a plurality of stirring blades 10, and motor 11 is fixedly connected on the upper end of pouring box 3, and stirring shaft 12 is fixedly connected on the end of motor 11 output shafts, and stirring shaft 12 Located in the pouring box 3, a plurality of stirring blades 10 are evenly distrib...

Embodiment 2

[0053] refer to Figure 7 , and embodiment 1 is different in that: the ram board 31 is an L-shaped plate, the air outlet 9 is a strip hole, the lower end of the ram board 31 is fixedly connected with a plastering board 18, and the plastering board 18 is slidably connected to the outlet Inside the stomata 9.

[0054] It should be noted that, in order to ensure that the pouring nozzle 15 does not hinder the movement of the troweling board 18, the troweling board 18 is designed to be in the same shape as the side of the pouring nozzle 15. It is located at the center directly below the pouring nozzle 15, and two plasterboards 18 are attached to each other in this state.

[0055] The horizontal reciprocating movement of the ram board 31 can simultaneously drive two plastering boards 18 to horizontally reciprocate slide in the air outlet 9, thereby smoothing the concrete spread by the spreading board 14, which not only saves a lot of labor costs, but also solves the problem of conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com