Well worker coal mine pipeline material conveying method

A technology for pipelines and coal mines, which is applied in the field of pipeline material transportation in underground coal mines. It can solve the problems of slow transportation of sand and gravel in underground mines, complex reverse transportation system, and long transportation time, and achieve fast transportation speed, simple system and convenient transportation. The effect of low labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

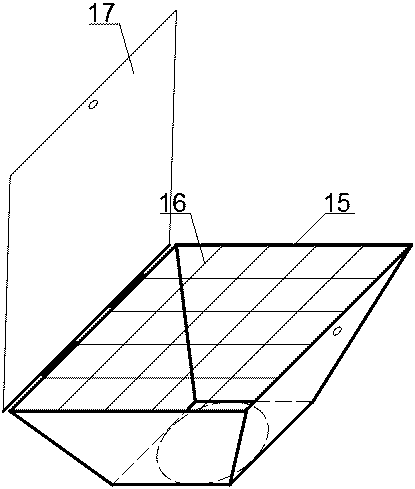

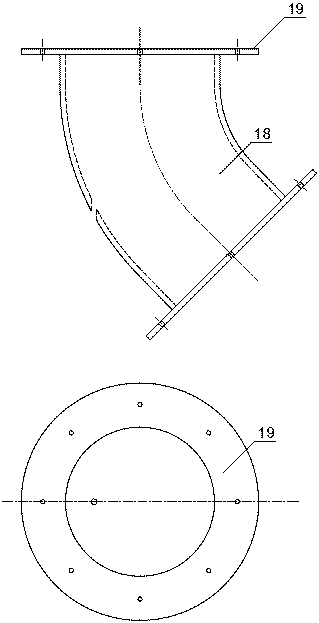

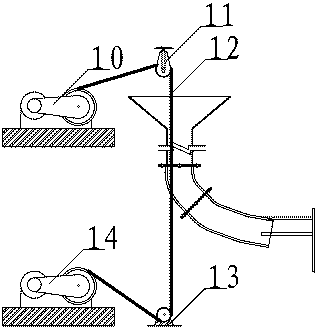

[0016] Such as figure 1 It is a schematic diagram of a coal mine underground pipeline material conveying system, including a ground funnel 1, a material conveying pipe 2, an underground material receiving chamber 3, an anti-blocking dredging device 4, an acousto-optic voice communication device 5, and a detachable anti-shock buffer elbow 6 , Outlet 7.

[0017] The material transporting steps of the method are as follows: the trackless rubber-tyred vehicle 8 for underground material receiving is ready → the underground personnel communicate with the ground personnel through the acousto-optic voice communication device 5 → use the acousto-optic voice communication device 5 to start ordering → the ground loading machine 9 loads sand Stone → Underground personnel observe the loading situation at any time → Finish when the material is full → Ground machinery stops loading → Transport to the specific construction site by trackless rubber-tyred vehicle → Ship the next trackless rubbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com